Last modified: 2025-04-24 21:27:38

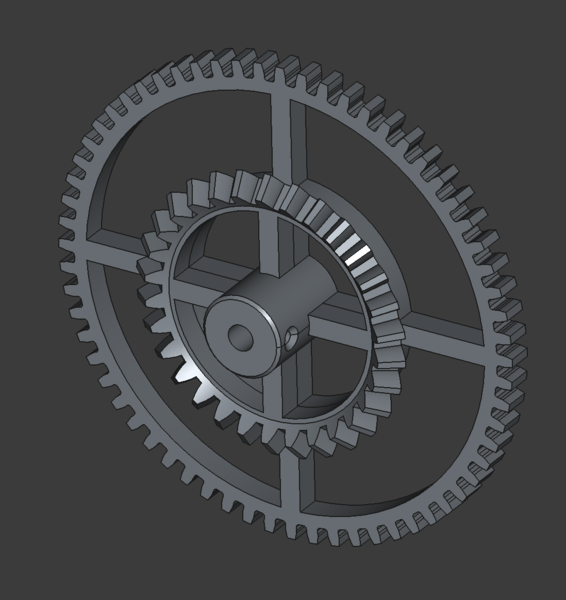

< 2025-04-18 2025-04-26 >I fitted the adjacent-arm thing with smaller gear, still too tight.

So now I'm going to finally get around to thinning the teeth on the gear that drives it. And then hopefully leave the clock running and get back to CAD.

Before:

After:

Also slimmed down in thickness slightly. Not as much as I intended. Really the bevel gear and the big gear could be in the same plane, but it is slightly annoying because you don't want the spokes interfering with the bevel gear.

Looks to be working!

I have also soaked some alcohol into some of the bearings, and put a second bearing on the remontoire middle piece, so that it is constrained a bit better.

Hmm, not working perfectly. Definitely better than before.

Both pallets escape at about 50 degrees.

Maybe it just takes a while for the bearings to get settled in their new orientation? To distribute the oil or whatever to places where it's not in the way?

Seems unlikely, but I can keep setting it running and see if it frees up.

It looks like it only winds successfully when the screw on the remontoire drive gear is pointing towards the adjacent shaft, and it is worst when it is pointing away.

That's actually the opposite of what I'd expect, because the screw should be pulling that side of the gear closer to the adjacent shaft. Is it possible that the issue was the size of the teeth on the big gear all along, and actually I want the larger pinion instead of the smaller one?

That's not the full explanation, it doesn't always work better when the screw is pointing towards the adjacent shaft.

Another idea I have is that one/some of the bearings are in at a slight angle and therefore there is constant pressure from one of the races. Unsure what to do about that. Maybe take it all apart and reassemble carefully?

I'm going to try the old catching-arm shaft again, just in case it helps.

It hasn't helped, might have hindered.

One thought is I may be focusing too much on the interaction between the big gear and the adjacent shaft, and not enough on the actual work being done of raising the remontoire weight.

But, no, actually, that's not the problem. With the remontoire failing to wind, I can lift the weight with my finger and it doesn't make any difference at all, it stays stuck. But if I push the catching arm around then it does start to move.

So it is hard to know what the actual problem is.

I've taken out the adjacent shaft and its bearings, and it definitely feels like one of them has more friction than the other.

< 2025-04-18 2025-04-26 >