Last modified: 2026-02-06 21:13:57

< 2026-02-03 2026-02-09 >I made up some discs on the CNC machine the other day to hold the spacers for the rear wheels, and today I welded the spacers to it and did a test fit of a rear wheel. It didn't go very well.

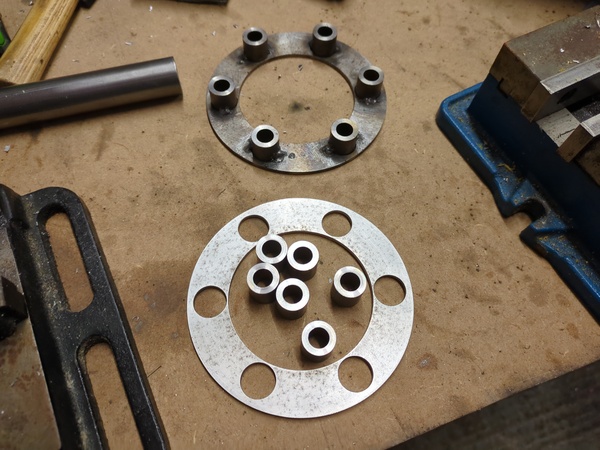

Here's before/after welding:

But when I tried to tighten the bolts on the wheel, this happened:

The hub cracked! Bugger.

So this is not going to be a viable way to mount the rear wheels, I'll have to find new rear wheels with a better way to mount them. I may still be OK for the fronts because the fronts are drilled at 80mm PCD instead of 100mm and they have more material on them.

If we say that a comfortable engine speed is 6000 rpm (I have no idea; but red line is 9500 rpm), and you'd want to be doing 50mph in top gear at 6000 rpm, then with a 16-tooth front sprocket on the engine (already) got, and a 10-tooth input sprocket on the gearbox and 12-tooth output sprocket on the gearbox and 1.3:1 ratio inside the gearbox, I think we want about 35 teeth on the rear axle sprocket.

I need to check that I can orient the 10-tooth and 12-tooth sprockets that way around. If not, then I think we want a 24-tooth axle sprocket instead.

And whichever size, I need to find the easiest/cheapest way to buy a sprocket that I can mount to the axle. The 24-tooth sprocket is smaller than the bolt circle on a BF12 hub which is slightly annoying.

OK so from having a look, the installed output sprocket is a 10-tooth 420 size sprocket, it seems to be pressed on to the shaft, I couldn't easily remove it. The installed input sprocket is 12-teeth and not clear what size it is. From a casual measurement it looks to be about 8mm between roller centres, and just under 4.5mm thick.

The eBay listing said it is for "#35" chain.

But it seems maybe a bit on the weak side, so I probably want to just use 420 sprockets everywhere.

One idea is that if the gearbox stops working but the input shaft is still OK, I could carry a spare sprocket to fit to the input shaft, and rejig the chains so that the input shaft is used as a layshaft.

OK, so to replace this gearbox input side gear - I could use:

The gearbox input gear wants to fit on a 5/8" shaft and have a 5mm keyway. I think I don't want to weld a different sprocket onto this one because I think the sprocket wants to be hardened and welding it would anneal it.

I can find 10T ones very easily on eBay that I think will fit, and can't find 11T or 12T, so 10T it is.

And then let's say a 28-30 teeth sprocket for the rear axle.

6000 rpm in top gear is:

Ideally I would find a cheap 420 sprocket with 28-30 teeth that takes a 1210 taper lock bush and then that's the end of the story.

I believe "420" size is the same as "#41". Also very similar to #40 but #40 is thicker so would need facing down on the lathe which is potentially OK.

For this one we could probably tolerate welding because the sprocket is bigger so loads are lower, still easier not to have to.

We have 3 degrees of freedom I think:

The approx. diameter will be 117mm, so to bolt to a hub the hub will have to be notably smaller than that.

I can get a kart rear wheel hub for a 25mm axle with 3x bolts at 58mm PCD for £20. Kart sprocket hubs are much too big.

Oh! They also have kart "split sprockets" that clamp directly to the axle with 2 pinch bolts and can be removed in 2 halves, this is interesting. Seems to only come in 428 size unfortunately.

There are Honda Z50 rear sprockets available in 420 size and 30T and with 3 bolt holes at 54mm PCD - seems like it wouldn't take a lot to make that fit on a 58mm PCD hub. Potentially the best thing to do is use an unmodified (or minimally-modified) monkey bike rear sprocket and eith make a custom hub for it, or make an adaptor to join it to the kart hub. That way I can easily get replacement sprockets without having to extensively modify them. Or maybe that's a premature optimisation and I should just do whatever is easiest.

I ordered a 29T 420-size monkey bike sprocket which has 54mm PCD, plus the kart hub with 58mm PCD. It's possible that the kart hub bolts are smaller than the holes in the sprocket and they fit already, otherwise it won't take a lot to open the holes up. I'm still unsure about hub-centric locating - there is a 30mm hole in the centre of the sprocket but unclear what size the spigot on the hub is, would 30mm be too much to ask?? Should be able to manage though.

< 2026-02-03 2026-02-09 >