Last modified: 2024-12-02 09:18:43

< 2024-11-30 2024-12-02 >Issues were:

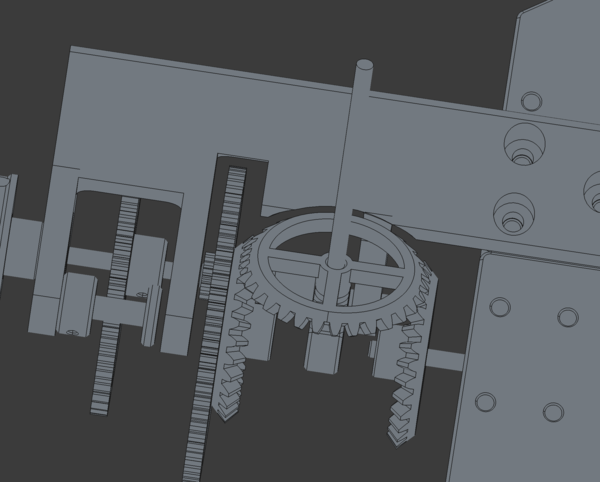

Lol, what an error on the gear ratio thing. I can't even just swap the gear sizes over because of the thing I did there the gearing is "inside" the group of bevel gears - the big gear won't fit!

It also won't fit through the frame.

I can still make the big gear integral with the bevel gear, just put it on the other side.

Cut-outs in the frame:

The catching arm and its small gear:

I made them as two parts because I thought each end would want to print against the bed, but the gear is actually small enough that that's not the case. But I can't be bothered redesigning it to be one part, I'll just print these two as is.

To reduce friction in the pivots I am making the through-holes 6mm, and just putting a 2mm-long 5.1mm diameter at each end.

Need to print:

I need to stop using grub screws to attach things to shafts, they damage the shafts too much.

The benefit of grub screws is it doesn't require any machining of the shaft, and the parts can be freely positioned axially, and the CAD is easy. The downside is you need to tap the thread.

Other alternative methods of keying things to shafts:

We can immediately discard splines, keys, woodruff keys, d-shaped shaft, and cross pins, because they all require machining of the shaft.

That leaves only clamps, press-fit, and glue. So I think it has to be clamps, but then the CAD is a faff, and I don't actually know how to do it in a way that can be 3d-printed and doesn't distort the associated gear.

Maybe a clamp piece with threaded holes in it, and then we bolt the gear to the threaded holes? With enough clearance in the clearance hole that the distortion of the clamp doesn't pull the gear out of shape.

It's working!!

There is still a lot of friction, so I am running it with 5x M20 nuts plus a big allen key, but it is working!

I still have 3 bolts as balance weights.

Hmm, sometimes it is getting stuck and not doing a full wind, but it does catch up eventually. A bit like how it was running yesterday.

I think the problem is with the friction in the pivots. Adding more drive weight just puts more weight on the pivots which wastes most of your extra torque as friction.

I think the most important friction is the pivots on the "remontoire-catching arm", because that spins faster than anything else.

I dropped some oil on those pivots and I think it might have freed it up? I also oiled the teeth on the pinion, not sure if that was more or less important.

The catching arm is now slamming quite vigorously, I may need to reduce the drive weight.

I don't have anything constraining the middle part of the remontoire axially, and it sometimes drifts to one side and binds up. I have added some shaft collar clips.

I'm going to stop messing with it now and let it run for an hour or so and see what the plot looks like.

This is 5x M20 nuts plus a large allen key plus a pair of nippers.

Averaged:

Non-averaged:

The amplitude was rising the entire time. Almost an hour! Is that because of parts wearing in, oil getting distributed, etc.? Or is it just that with so much weight on the balance wheel it just takes a long time for the amplitude to change?

The amplitude-period relationship looks quite tight, but it varied by like 20 milliseconds over 40 degrees, which is pretty bad compared to previous runs.

I'm going to rewind it, make no changes, and start it off with about 240 degrees of amplitude.

I noticed that the remontoire was slamming very violently, so I removed the allen key and nippers, but now with less weight hanging off the back of the frame, the frame is able to spring together slightly which now pinches the balance pivots which I've had to re-adjust. FML.

I really need to switch to a metal frame.

I found that the remontoire was again not rewinding reliably, so added the allen key back.

Adjusting the balance pivots was a big help, amplitude is now up to about 255 degrees, with no change to the weighting of the remontoire.

The escape wheel skipped some teeth on one occasion, so I decided to move the remontoire weight to reduce the amplitude

Check this out:

The period-amplitude relationship was initially inverted!

Then I reduced the remontoire weight and we have the widely-spaced dots during the transition, and then with less remontoire weight it's much closer to isochronous, just moving left and right at about the same period. The Y axis spans about 9 milliseconds, so the region at the bottom is easily under 0.5 milliseconds.

But I've learnt here that the relationship between period and amplitude is affected by the amount of drive torque, beyond just the effect that torque has on amplitude.

Zooming in on that region:

(After running for a bit longer).

It kind of looks like it reaches a minimum around 250 degrees, and goes up either side. The trailing off at bottom right is because it ran out of string.

Tomorrow I should run it for longer without touching it and see what happens.