Last modified: 2024-11-25 15:07:33

< 2024-11-20 2024-11-25 >Ideas to try were:

Let's try 6 nuts.

About 205 deg. average amplitude. Definitely getting into frictional rest, but the period variation is still dominated by the fluctuating drive torque due to the gears meshing.

I tried putting oil on the teeth of the meshing gears but it didn't produce any observable effect.

The idea is this will increase the dominion of the balance over the train.

The downside is it will put more weight on the bottom pivot, so increase the friction of the balance. And we would probably want a stronger balance spring to suit the heavier balance.

I've put 2x M12 bolts on the balance wheel.

It's not running with enough amplitude to enter frictional rest even with 6 nuts drive weight.

I raised the frame spring clamp by about 1mm and it increased the amplitude from 125 deg. to 145 deg., so weight on the balance pivots is a major consideration.

The period varies a lot more with the gear meshing now than it did before (150ms vs about 40ms).

So perhaps the reduced amplitude caused by increased friction has actually reduced the dominion of the balance.

And here it is with just 1 bolt on the balance wheel:

This is not necessarily sound because the balance is obviously badly out of balance, but it does show that reducing the weight on the pivots helps, bceause now the period variation due to meshing is mostly within about 60ms.

What's the easiest way to test out a roller lantern pinion? It should mesh with the existing driving gear.

I wanted to use sections of PTFE tube as rollers, but the gaps between the teeth is just slightly too small.

I could 3d print the rollers? Or I could print a new driving gear with larger gaps between the teeth?

I have some 2mm blued pivot steel rods which are a good fit in the PTFE tubes. And I'll design a modified driving gear that has more space between the teeth. The PTFE tube has about 4mm outer diameter.

So now I need 7 pieces of PTFE tube a bit shorter than 15mm long, and 7 pieces of 2mm pivot steel about 29mm long.

Here we go!

And now running with 6 drive nuts again, no balance weights, and spring re-adjusted so that the balance pivots have approx. no load.

It occurs to me that adjustable depthing might be very helpful. Maybe if you can get the depthing quite precisely correct then maybe that would smooth out the power transmission?

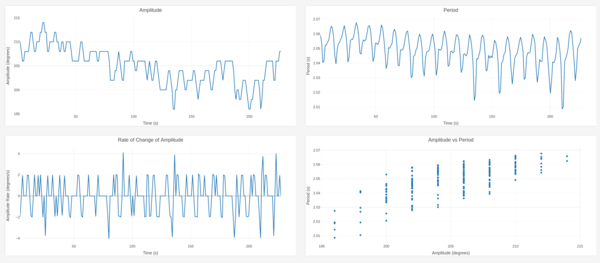

So we have amplitude from 205 to 230 deg., and period from 2.045 to 2.085 seconds.

Whereas previously we had amplitude from 195 to 215 deg., and period from 2.010 to 2.065 seconds.

So this is not obviously a massive improvement, but it's definitely not worse.

It doesn't look like the rollers are actually rolling, I'm going to try adding some oil to the pins.

Doesn't seem to have made any difference. Does adding oil ever do anything?

I have adjusted the depthing by loosening the mounting bolts and wedging a pair of tweezers between the shaft bearing block and the frame, and it has reduced the variation in the period! So depthing matters.

Looks like another error where a half-period was about 0, but apart from that you can see the period variation is much reduced, and also minimum amplitude is increased, from 205 to 220 deg.

Reduce radius of resting surface

It occurs that this will probably want yet another new escape wheel. Never mind. I'll just use the smaller pallets with the existing escape wheel and see what happens. Probably I'll be able to put more teeth on it which would be good.

I've installed the smaller pallets, but twisted the lower one around to reduce the "drop".

This looks like a big improvement over before.

Even with the depthing experiments undone (so, back to "default" depthing by just clamping the parts up tight), the period variation is down to single-digit milliseconds, and the amplitude is getting up to 290 degrees!

One issue is that the amplitude goes so high that the twisted pallet sometimes falls off the end.

The period is up to about 2.11 seconds now. The natural frequency of the balance is about 2.12 seconds, so we are getting closer to it, which suggests the balance is gaining dominion.

And the "heartbeat" from the gears meshing is basically gone.

We are now seeing a "heartbeat" from the rotation of the escape wheel, approx. every 2.1 * 37 = 77.7 seconds. Presumably caused by the slight wobble in the escape wheel. Not obvious to me why this still affects the period but the meshing of the gears doesn't. Maybe it means the point of unlocking is now more important than the exact drive torque?

That's a trace of it running for over 20 minutes.

And every single tick of the balance here was within a range of 16 milliseconds! And the biggest outliers are caused by skipping when the amplitude gets too high. Plausibly the amplitude could go even higher if it was allowed to keep the extra energy.

I let it run until it ran out of string:

(That's the same trace, but continued slightly longer).

The balance only barely speeds up as the amplitude drops off when the power runs out, so perhaps it is pretty much at the natural frequency already?

McEvoy and Betts' "Harrison Decoded" has this plot of Clock B's rate:

Wow! That is on another level. That is a plot over 16 days where the time of a 1-second beat never changes by as much as 0.005 milliseconds! Although I don't know how much smoothing is being applied, because we're obviously not seeing 86400 datapoints per day. If I averaged over 20 minutes' worth of data points from my run I would see a pretty smooth line as well. I wonder what the actual jitter in the rate was.

It says at the top that the number of samples is 14095, which over 16 days works out to about one per 100 seconds. Maybe the MicroSet device is not even reporting the rate more frequently than that?

I wondered if I took only every other amplitude/period reading if the chart would look any smoother. It turns out it doesn't:

So I'm just going to stick with the prior chart.

Resting-wheel verge escapement

I saw this picture in Daniels' "The Art of Breguet":

It seems basically equivalent to what I have now, except it removes the recoil because when a tooth escapes one pallet, the tooth landing on the other pallet hits the resting after the point that the impulse surface has already gone past. This seems like an obvious improvement.

It's like 2 copies of the "one-way roller escapement", from 2023-12-29.

With the new reduced resting radius I think this might work with the existing balance wheel.