Last modified: 2024-11-26 14:58:00

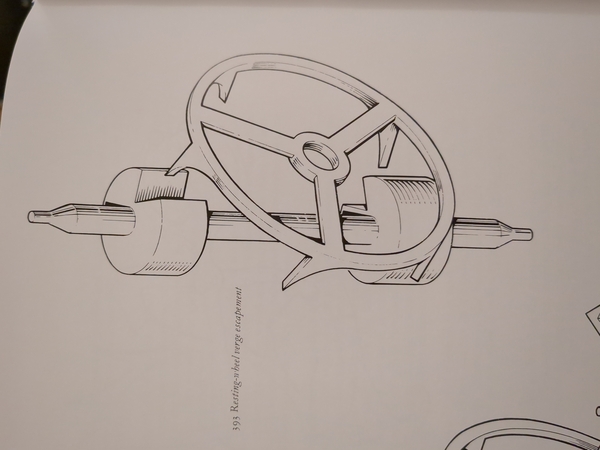

< 2024-11-21 2024-11-26 >Resting-wheel verge escapement

The plan is to make a version of:

to put on the test frame, and see how it goes compared to the previous versions I've tried.

And then stop messing about with the escapement and build the rest of the clock!

I think reduce the resting radius further, and make the escape wheel smaller accordingly. (Later on, could increase the number of teeth, but better to compare like with like for now).

Also I've put some washers on the second shaft bracket to increase the depthing slightly. From spinning it by hand I noticed that the tooth tips are catching on the rollers as they come into engagement.

This is looking really good.

So here (after the initial ramp up while the amplitude is reaching a steady state), every data point is within a range of about 6 milliseconds. The previous best was 16 milliseconds, so this is a lot better.

Also, I'm only running this on 3x M20 nuts for a drive weight and the amplitude is over 200 degrees.

We see a very clear cycle with a period of about 78 seconds, so that will be the rotation of the escape wheel.

The period is getting much closer to the 2.12 seconds that I previously noted was the natural frequency of the balance, so that's good.

I also have a new feature in clockwatcher:

74 samples is one rotation of the escape wheel, so this completely averages out the variation throughout the escape wheel rotation.

And the amplitude vs period plot looks pretty linear! After the initial ramp-up period.

And running faster in the longer arcs.

The period averaged over a full rotation of the escape wheel stays within 3 milliseconds here.

Scrolling the moving average up/down and looking at the amplitude/period plot is a good way to find the variation period! If the number of samples is not synced to the variation period then you get loops in it:

Which are minimised when your moving average size matches the variation period, which in this case indeed minimises the loops at 74 samples.

Also one of the pallets is catching on the escape wheel teeth as it swings back towards it. It is making a "tick... ta-tock" sound. So I should move the escape wheel slightly further away. Also keen to try with more drive weight. And maybe try to make the balance shaft more perpendicular to the escape wheel shaft.

OK, I have improved the depthing and straightened up the balance shaft.

The escape wheel is showing a slight recoil just before escaping from the upper pallet. I think perhaps the resting surface is slightly bulbous near the corner?

This is even better. The averaged period is within 0.6 milliseconds over a 25-minute run. And the absolute period is within 2 milliseconds.

The period seems to be trending down over time, perhaps because it is night time and the heating has gone off, so the room is getting cooler? I should add temperature monitoring.

It would be good to get a trace of it running over an entire day or so to see how it varies throughout the day. Need more gearing for that.

I have a suspicion that some of the variation is from the tension in the winding of the string, and the snaking of the string across the winding drum. I should put a helical groove in the winding drum so that it doesn't snake, and add some sort of winding ratchet so that I can keep consistent tension. And maybe replace the cotton string with fishing line or something.

Now I'm going to go up from 3x M20 nuts to 6x, like before, and see how it performs.

If you ignore the first ~78s worth of data (because that's not averaged over the full 74 samples) then we're within 0.3 milliseconds over almost 20 minutes, and the amplitude is up to about 285 degrees.

I adjusted the balance spring so that it was closer to taking exactly the weight of the balance. Still running with 6 nuts.

The amplitude is up to maybe 305 degrees, but it is occasionally skipping teeth and the period stability is much worse.

I tried to adjust the depthing to fix the teeth skipping, but I can't get it to work. I think the balance shaft perpendicularity is out again. This can move every time I adjust the pivots if the pivots aren't properly concentric. I probably want independent adjustment of the pivot location and height. I.e. like it is now, but in a separate piece that can slide around on its mounting holes slightly, so you set the height of the pivot, and then with that fixed in place you can move it around to adjust the upper and lower depthin independently.