Last modified: 2024-11-20 23:23:01

< 2024-11-19 2024-11-21 >I have the new escape wheel and pallets installed. Going to run it with the monitoring, pallets parallel, one nut, and about the tightest possible depthing.

First go:

Compared to the previous test in same conditions (1 nut, "best" depthing, parallel pallets):

So, good.

It did look like the escape wheel is closer to the top pallet than the bottom one, some of the teeth were rubbing the shaft.

Maybe I now actually want some "rest of the clock", so that I can run it for longer?

Maybe I do it first without any kind of remontoire, and then add the remontoire and I get to see what improvement it makes.

I have run out of 5mm aluminium rod for making shafts, so ordered more of that. Also ordered more of those little bearings. They are 10mm outer diameter, 5mm inner diameter, 4mm thickness.

I was considering trying to design the frame part for the new addition so that it would be able to accommodate the remontoire later, but I think easier just to make a minimal frame part now and make a new one to suit the remontoire when I am ready for it.

The FreeCAD InvoluteGear "Profile Shift" setting is good, I am setting it to -0.1 to create clearance between the gears.

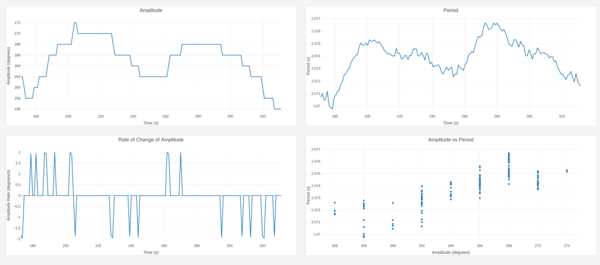

We see that the period goes up as the amplitude goes up, so to speed it up in these cases I think we would want to make the backs of the pallets get wider as they move further out, which is the opposite of what H4 had? We want excess power from the escape wheel to speed the clock up as amplitude increases, compared to what we have at the moment.

So why is that the opposite of what H4 had? Is it because my pallets have a lot more friction, so the retarding effect of the frictional rest is stronger than I want? Whereas in H4 the retarding effect was not strong enough?

Or is it more complicated than that, and the variations in period I'm seeing here are basically fine, and it's variation with temperature etc. that the shape of the pallets is really there to contend with?

Once I'm able to run the escapement for longer and get longer data traces out of it I'll probably have a better idea.

This is what I'm going with for now:

I'm too impatient to wait for the shafts and bearings to arrive, so I've rummaged in the garage and found a 5mm steel rod, it's a bit rusty but I polished it up slightly in the lathe, should do the job.

And I'm 3d-printing some simple bushes to go in the bearing holes in the frame, maybe I'll put a drop of oil on them, and hopefully I can see it working tonight.

I'm taking a trace with 2 nuts for drive weight. This is going to be less than half as much actualy drive torque as 1 nut was before, because the gear ratio is like 4.1:1.

The first observation is that the period varies periodically, with like a 11 second cycle or something. I think this is how the torque delivery varies at different points throughout the tooth engagement?

Whatever the cause, this effect basically dominates any variation in period caused by variations in amplitude:

So this is one good reason to use a remontoire. And I'm glad I took some measurements of how the clock was running before adding this extra gear, because I might not have guessed that it would make such a stark difference.

The first run today had a period variation of only 7ms, whereas that segment, which is basically the same configuration except the drive torque is geared down, shows a variation of about 50ms.

Actually maybe I should just increase the drive weight such that the amplitude is the same as it was earlier today, and see how it behaves then? The amplitude here is too low to ever enter frictional rest.

From watching the live plot and the gears at the same time, I have confirmed that the periodic signal in the period chart is synchronised with the meshing of the gears. So that's very interesting! Maybe a lantern pinion would help, I should maybe try that.

Here's a longer trace of the same setup:

But it's so long now that data is sliding off the left-hand edge. I will increase the amount of datapoints that clockwatcher tracks.

Although the variation from the meshing of the gears shows up starkly in the chart - it isn't necessarily a big problem, especially in the "later" gears, closer to the escapement, because the error will average out over time. If you have a gear that only moves through one tooth per day then maybe it matters on that gear.

Here it is with 4 nuts:

I guess it saw one datapoint with approximately 0 half-period which caused the weird spike, e.g. bouncing on the encoder. Annoying.

If 4 nuts will only run it for 20 minutes, then I'll need 26k nuts worth of weight to run it for a year, if my gear train has 0 losses. A nut is 87 grams, so 26k nuts is 2260 kg. So this is not going to work. I need lower friction pivots all around, and a more efficient escapement (smaller resting radius? or something else entirely?).

Another plot with 4 nuts, same setup as above:

One reason for the small number of random macro changes in amplitude could be that the drive weight starts swinging in resonance with the balance? I can see the drive weight swinging around slightly, and I don't see why it should be swinging if not for resonance with the balance.

So current ideas for things to try:

My ABS-GF spool has arrived, so to try it out I'm going to use it for the bracket that holds the new shaft on the clock.

I'm expecting from this material mechanical properties broadly in line with PLA, but better temperature resistance and a cool surface texture.

From https://bambulab.com/en/filament-guide :

I've just noticed the smooth plate says to apply glue stick before printing except for PLA, which I did not do. Oh well, let's see what happens.

Well it didn't damage the bed, and it prints really nicely:

< 2024-11-19 2024-11-21 >