Last modified: 2024-06-22 10:13:25

< 2024-06-18 2024-06-27 >I've got all the supplies I ordered except the rubber washers, which annoyingly means I can't put the machine in the tub just yet. But I can reassemble what I took apart, and see if I can try to measure how square the axes are. Also can potentially drill the gantry back support pieces.

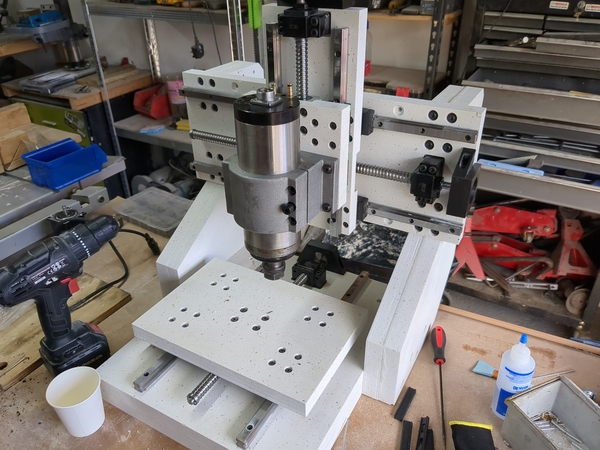

Looking good:

Just realised I don't have a connector to plug into the motor, what kind of connector is this? I know this is one that I fitted to it myself to match the one from the 6040, because this motor came with a GX20 or something on it.

Looks like I didn't say in the notes what kind of connector it was.

I think it's an H20 plug. (For the 2.2kW spindle motor, or 1.5kW spindle motor, or 6040 CNC machine).

Not very expensive but only available direct from China. Never mind.

Next up I can try to drill the holes for inserts in the gantry back pieces.

Clamped in place, drilled to mark the holes with 6.5mm drill, shuttled the carriage back and forth with "clamp sokoban" to keep it clamped in the same place but expose different holes. Unclamped, drilled the 8 front holes with the pillar drill, started drilling the 8 side holes using the cordless drill, but battery went flat. So the battery is on charge.

Next time:

For the wiring I'm thinking I'll mount a plywood board on the wall, which the VFD can screw into, and also the plywood board will hold strain relief for all the wires. And if I think it seems a bit dangerous, I can 3d print a cover to go over the screw terminals, which can also get screwed to the plywood board. Maybe use that on/off switch that I never fitted, to switch power to the VFD, so that I can turn the VFD off in a hurry if I need to.

< 2024-06-18 2024-06-27 >