I'm working through the book Lathework: a complete course, and it is suggested that benchtop lathes really need to be bolted to something sturdy in order to do accurate work, because they lack the required rigidity. Bolting to a plywood workbench is not enough, because to make the lathe turn parallel you need to adjust the mounting to take the twist out of the ways, which means the stand needs to be broadly as strong as the lathe bed otherwise you will twist the stand instead of the bed.

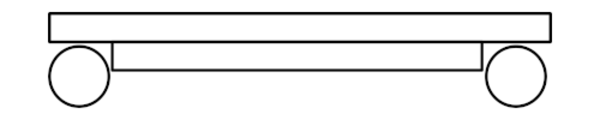

The stand I have built is a "spanning beam" stand, which means the lathe is bolted to a beam which is only supported at the ends. Supporting the beam in the middle is supposedly to be avoided, because if supported in the middle it is possible for the beam to be bent by changes in the load distribution, whereas 2 points always describe a straight line. However for my purposes I think it wouldn't make any difference.

There is a good page about making such a stand, along with several examples: Make a spanning beam metal lathe stand easily.

A while ago I removed some old gates and kept them around for the steel tubing:

I prefer using box section because then you don't have to notch the tubes, but it's hard to beat free.

Spend a few hours cutting the welds off, grinding them back, stripping the paint with a wire wheel, and cleaning up the big dusty mess of rust and bits of old paint, and you have a collection of usable tubes:

I was surprised to find that some of the tubes had been galvanised before they were painted and some had not, also some of them had welded joints in the middle. Were these gates DIY'd by someone who had themselves rescued the tubes from something else? I wonder what previous life they had. I wonder what future lives they may have.

I didn't take any pictures of making the actual beam. As you can see, it is a piece of rectangular box section with some thick lugs welded into it. (This was not part of the steel gates, it is steel I bought for the racing mower front axle but ended up not using).

I laid out a "jig" for welding the end supports on a piece of MDF:

This worked quite well, and I got a nice matching pair of supports:

Welding the rest of it together in thin air was a bit more Heath Robinson, but eventually I arrived at this:

There are nuts welded into the bottom of each tube, to provide for the leveling feet.

It is painted in silver Hammerite paint:

The paint is meant to have a hammered effect, but I would describe the effect as "subtle".

And here is the stand installed, with the lathe bolted to the top:

My garage floor is not very level (compare the adjustment of the leveling bolt on the rear left corner to the front right corner).

Around this time Emma and I tore down an old shed, and I managed to salvage a couple of big sheets of OSB, from which I made shelves for the lathe stand. I prefer plywood, but again it's hard to beat free.

The idea is that the bottom shelf would just be used for storage, and the top shelf would be used as a working surface, and would likely collect lots of swarf. To make the OSB more palatable as a working surface, and to aid sweeping of swarf, I decided to seal the surface with a healthy coat of PVA:

I came back out the next day, ready to fit my shelf, but it still wasn't dry:

I suggest if you are going to do similar you should probably dilute the PVA with water. I left it by a radiator for another day and it eventually dried to my satisfaction.

The top shelf is mounted with screws through the steel tubes. The bottom shelf just sits there under gravity. Since the OSB is a bit too thin to be used unsupported, I have doubled up on the material to stiffen it up, with the top layer spanning across the steel tubes, and the bottom layer sitting between them, like this:

With the shelves installed, the first lathe job was to make some nylon bungs to block up the tops of the exposed tubes:

And finally an Ikea "Helmer" drawer cabinet screwed down to the lower shelf to house the various lathe paraphernalia:

(Yes, I deliberately spaced the horizontal tubes exactly far enough apart to fit a Helmer cabinet. I really like the Helmer cabinets. I have 4.)

I'm still working on the first project in the lathework book (it's a "mini surface gauge", you can see a drawing of one of the parts on the wall behind the lathe), and so far I have found using a dedicated stand to be much more convenient than dragging the lathe out and plonking it on the workbench, although I can't say I've noticed any performance improvement from the increased rigidity. But the second project in the book involves measuring and correcting the twist in the bed so that it turns accurately parallel, which is when my lathe stand will really prove its worth.