Last modified: 2025-06-13 22:31:25

< 2025-06-09 2025-06-14 >I'm expecting the motor to arrive today, would be good to spin it up and see that it works.

The motor listing says that its "rated speed" is 2750 rpm. I don't know if that is the speed it tops out at or not, will have to see when it arrives. But let's assume that's how fast it will spin at top speed.

The rear wheel diameter is about 430 mm.

I want the tractor to go maybe 6 mph, which is 9.65 km/hr, or 9650 m/hr, 160 m/min.

So in 2750 revolutions of the motor we want to travel 160 metres. 160 metres is 372 revolutions of the wheels. So we need to gear the motor down by 2750/372 = 7.4x.

That may be a bit much to do with just one stage of sprockets. The motor comes with an 11-tooth drive sprocket, so I'd need a ~81 tooth rear sprocket. The sprockets it comes with are described as "25H".

An 80-tooth 25H sprocket is available on eBay, so maybe that isn't outrageous. It has 160mm diameter, so fits well within the size of the wheel. So maybe I just buy an 80-tooth 25H sprocket? It's only £7, can't go wrong.

I think try to measure the chain that arrives to check that it actually is 25H, and spin up the motor to check that it actually does spin at 2750 rpm, and if both are so, then buy the £7 sprocket.

And then for the rear axle I think I want some 19mm diameter steel that is 800 mm long, and matching bearings.

And for the front axle I want some 16mm diameter steel, which I'll maybe bend (?) or else somehow fabricate into stub axles and kingpins. Kick that can down the road I think. Maybe an M16 bolt would be better.

The closest Rapid Metals had to 19mm round bar is 19.1mm, I guess that is slightly over 3/4 of an inch, which is 19.05mm. Oh well, probably close enough. I just need to be able to jam it through the wheels I have.

And, great, of course nobody makes bearing blocks to take a 19mm bar. Maybe I would be better off getting a 20mm bar and turning the ends down to 19mm? I'll do that. And I'm getting "UCF204" bearing blocks for the rear axle.

OK, the motor kit arrived. I got it all wired up. The motor spins at 3660 rpm with no load on it! So that is 1/3 more than specified, so I'd need a sprocket with 108 teeth to make it top out at 6 mph.

I haven't seen any larger than 80 teeth available. So the other option is to go down to 8 or 9 teeth on the front sprocket. Or else reduce the top speed by limiting the throttle pedal travel, or adding some constant friction brake to the axle.

With the suppled 55 tooth rear sprocket it would go 11.6 mph, which I feel is too fast. If I put an 80 tooth rear sprocket but kept the 11 tooth front sprocket then it would go 8 mph. Maybe that is acceptable to start with.

ChatGPT reckons 4 mph is more sensible.

Well I definitely can't get a 162 tooth sprocket. Maybe I just fit the 80 tooth sprocket and limit the throttle pedal travel.

Actually, update: I can get a 92 tooth sprocket. Will do that and see how we get on.

Mark suggested 3d-printing the bodywork. Obviously it is too big, but I could use plywood for the flat parts, 3d-print the rounded parts, fix it all together and bodyfill the joins. Maybe that is the best way.

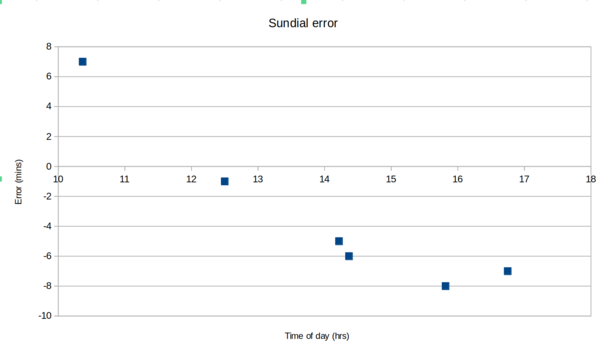

I have been collecting some samples of the sundial indicated time and the time of day, and plotted the implied error throughout the day:

It is ahead in the morning, pretty much right at noon, and behind in the afternoon.

I think this means it points north pretty accurately, but is tilted towards the west? Or east?

Actually, I think the shadows are basically always pushed further towards noon than they should be, which means it is tilted north? Or south?

< 2025-06-09 2025-06-14 >