Last modified: 2025-05-27 17:02:00

< 2025-05-25 2025-05-28 >The plan is to attach a Horolovar anniversary clock suspension spring to the existing frame and balance shaft, that the clock might use up energy much more slowly.

At this point I don't care how well it keeps time.

I have a suspension spring that is 140mm long, with rectangular cross section maybe 0.4mm by 0.1mm.

It seems like it would be hard to capture this with a 3d-printed part, I may need to make metal clamps for it. Or make my 3d-printed part take a small screw in each side and clamp the spring between two screws, like the upper clamp of the existing balance spring.

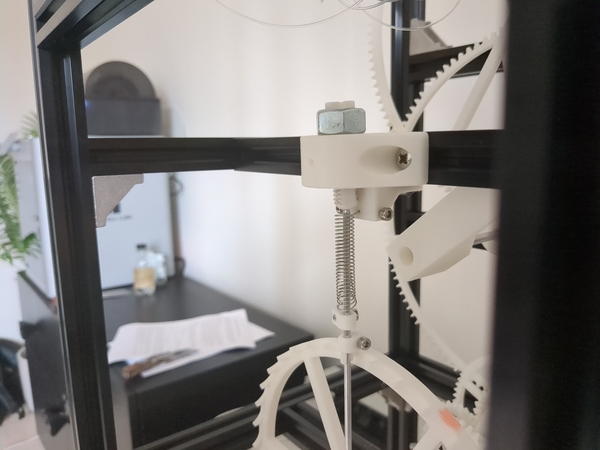

The top of the balance shaft is currently like this:

So let's imagine ditching the top pivot and existing balance spring, cut the shaft shorter, add a fitting to the top of the shaft to grab the bottom end of the new balance spring, move the horizontal frame member further up, and add a fitting to the frame to grab the top end of the new balance spring.

It may want to be quite finely adjustable in all 3 axes so that the balance shaft can be aligned with the escapement. But maybe worry about that later. Just make it work for now.

And I only have about 140mm between the top of the upper pallet and the bottom of the winding drum so I may have to cut the spring down slightly.

If the top clamp is centered on an M12 thread then I can use the existing bracket to attach it to the frame. Maybe unnecessary.

Something like this to clamp to the balance shaft:

So the balance shaft goes in the vertical hole at bottom left. Clamping screw at bottom right. Suspension spring goes down the small vertical hole at top left, and has clamping screws at top left.

And then a similar method for clamping the spring, but a bracket to bolt it to the frame...

Something like this:

OK, here it is installed:

I haven't got it aligned well enough to actually tick yet, but the balance period is about 38 seconds, up from 7.5 seconds. So yeah this now uses up energy much more slowly. If it would run for 2 weeks before then it would run for about 10 weeks now.

I think the spring could do with a bit more tension on it, because very small forces on the pallets can push them out of line by more than their size. So potentially we can get an even longer period by adding more weight.

Whoa, I got it to tick a few times! Just with hand pressure on the train. The balance shaft is wobbling a bit too much though, so it sometimes skips escape wheel teeth.

I think I have it aligned such that it works and doesn't skip teeth any more.

So next thing is to hook up the clockwatcher, hang the drive weight on it, and let it run for a while and see if it actually does work. And I still think it might benefit from more tension in the suspension spring.

It is still skipping some teeth. Amplitude keeps growing, I expect it will grow to the point that it skips teeth at the back of the pallet. It has got up to about 290 degrees.

The amplitude measurement is under-reading, because the quadrature encoder keeps reversing by one step which makes it reset the presumed extremity of movement in that direction. I think possibly because the balance shaft is wobbling.

The balance period when it's running in the clock is more like 42 seconds.

The cord is all tangled on the winding drum but it seems to be winding the remontoire anyway so I'm just going to leave it for now.

Update: it stopped after a bit over an hour. Remontoire not wound. I'll untangle the winding drum and give it another go.

Meh, it keeps skipping teeth still. I'm going to try adding more balance weight.

Darn, I'm out of M12 bolts.

It probably wouldn't help much anyway. I probably need to increase the pallet engagement.

< 2025-05-25 2025-05-28 >