Last modified: 2024-11-01 14:15:51

< 2024-10-29 2024-11-01 >Working through the TODO from 2024-10-29...

V-bit path: lighter cuts, and stepping over 1mm instead of 0.5mm.

Aligning the top and bottom sides: probably I have to drill a couple of alignment holes using the machine, and pick them up when I flip it over.

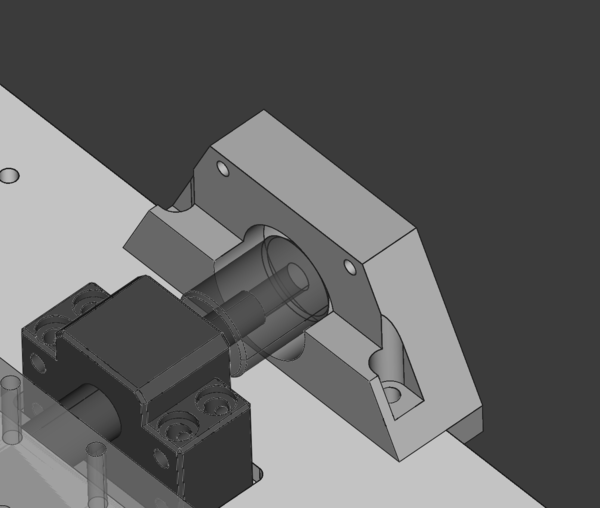

Y motor bracket: this wants redesigning to have a cut-out in it to let the table go back a bit further. I won't bother reprinting it, but it will be in CAD for if I make another in future.

Also gives better access to the coupler.

I've ordered a new v-bit.

More efficient slotting toolpath: skip the profile/slot at Z=-1.5, and for the small coins only do one lap of the final profile, at full depth.

One thing is that by copy-and-pasting the model across all the CAM files, if I make a change to the model it doesn't automatically get picked up in the CAM. That's maybe a drawback of this workflow. Although the other thing is that if I want to make changes to the model for any particular job, it doesn't break the other jobs. Very tricky.

This is where being able to use git and diffs etc. would be so handy.

Diffing is still handy, I've been merging the changes to the CAM jobs and diffing the generated gcode and noticed that the TagDressup on the profile has gone missing. Not sure how that's happened.

I added the TagDressup back and diffed my gcode to make sure it looked like the body was now 0.25mm shorter, but doesn't obviously seem to be? And loading the gcode in FreeCAD shows that it is unchanged. Why is the Path job not picking up the change to the model? And now FreeCAD has crashed. And FreeCAD can't even open the FCStd file any more, just nothing happens when I try to open it. Maybe try FreeCAD 1.0rc2?

Lol, and now the Ubuntu Snap Centre won't even load. What is going on? Probably nvidia driver nonsense. I think reboot.

The file opens now, but it's still not regenerating the path to match the modified model.

I opened up the Profile operation and closed it and now it has done it. Pretty bad.

Good, and now vimdiff is showing the difference. While I'm looking at the profile job I'll also slow down the feed rate and reduce the stepdown.

Woah, the ubuntu file picker lets you add bookmarks, this is super handy.

Maybe instead of changing the sizes of the slots I should have just put a negative "stock to leave". Never mind.

Clear the centre pip on the pockets: my strategy here is going to be to change the stepover until it looks like it will clear it. Actually, change of plan. I'll just manually write some gcode to

do a short line across the centre of the pocket and gcode-cat it into the path.

Make the stand wider: the beam is 8.5mm wide so the gap between the wings on the stand needs to be more than 8.5mm. The distance across the gap between the grooves measures 9mm now, maybe it will work this time.

Make a peck-drill job for the stand: done.

OK, great success, I think we're almost ready to have another go.

The plate is already bolted down to the table, which is handy. I will drill alignment holes and locating holes for the bolting holes without taking it off the table, then take both sheets off and drill out the bolting holes to 7mm, then bolt it back down using the new holes.

OK, parts cut out:

Looks like the stand was cut out in the wrong place.

Notes from running the gcode:

bolting-holes.nc has a bunch of M2 in the middle of it - is gcode-cat not working? same for stand-drill.ncslots-rough.nc has some XY moves at F50 instead of F100slots-rough.nc has a pointless Y moveMoment of truth: does the coin balance?

...No. The coin is much too heavy this time! How has this happened?

This time it only weighs 32.4g. There is a lot more material removed in the score lines, but I thought that should have been accounted for in CAD.

Oh! I haven't folded down the wings yet. Will that make enough difference? It makes a bit of a difference, but not enough. I think put the counterweight back to 40mm, and plan to manually calibrate them. I'm going to do a bit of vibratory tumbling of this one to see how it comes uot.

If you select a CenterOfMass object and then click the CenterOfMass button, it hangs FreeCAD.

I designed a coin box with a print-in-place hinge.

It is 2 identical halves like this:

Closes up like this:

It stores 5 coins together without letting them scratch each other.

Not too bad for a first attempt but: