Last modified: 2024-10-29 21:56:52

< 2024-10-27 2024-10-31 >It's time!

I'm just going to make one, and try to do it well.

So I need to know where I'm putting holes in the sheet, and then Gcode for:

I manually wrote gcode for the score lines, based on coordinates from CAD.

Drilled mounting holes need to be at:

First blunder: I got the top and bottom side reversed...

So we're putting the score lines on the good side of the brass and making the top surface out of the bad side. Never mind.

I ran it at 50% feed at first. Going down to Z=-2 at 1mm step down with the v-bit is not going to work.

Great, the v-bit is broken. Oh well, I have some grooves. May need to make the toolpath a lot lighter.

Now we need to flip over and run pocketing with the 6mm tool.

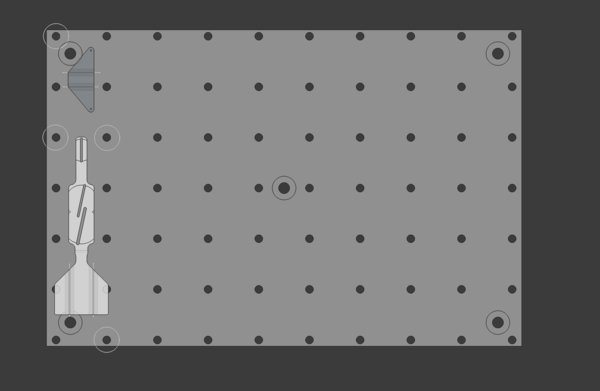

Workholding is like this: https://img.incoherency.co.uk/img/5649

The sheet was vibrating a bit during pocketing, maybe need to use tape to stick it down as well as the bolts?

Now we need a slotting path.

The best strategy for this was to do FreeCAD Helixes at the end points of the slots, and then manual slotting for the centre, and then a FreeCAD Profile to clear the outline, but skip the material that is already gone.

The chatter appears to be solved!

Is the cutter going to hit the screw heads?? FML, I thought I planned for this. The heads are a bit over 13mm.

I think it won't quite work. I'll replace them with bolts with smaller heads.

OK, slotting time...

Slotting went pretty well, but time-consuming:

Now we need to drill pivot holes in the stand, and then cut out both parts.

Pivot holes are at X28 Y187 and X28 Y150.

This went OK, quite chattery, I think the depth of cut was too much for this workholding. Also the tabs on the stand part weren't enough, it got flicked loose right at the end.

Next up is getting the beam loose from the sheet, filing down the tabs, and drilling the pivot hole.

The score lines on the counterweight are not very well aligned:

Now I guess try to make the bends. I'll try and wing it first, but I can 3d print some forming dies if it would help.

First the stand:

I found a couple of random pieces of metal to use as a die. And the bending worked, but the holes don't line up very well (maybe just due to alignment of top and bottom side?), and the gap is too narrow, lol. So this won't work.

And the counterweight:

This time I clamped the "wing" in the vice and folded down the body with my hands. It was difficult but worked. Again the alignment is poor. Also, as expected, there is not much of a gap once it's folded to 90 degrees, so I would want to increase the size of that gap to get a tighter bend.

And the most important question: does it balance?

...No. The counterweight is too heavy. In total it weighs 34.9g vs 33.9g in CAD.

Also the 2009 sovereigns are like 1.65mm thick. Are they fake?

Paul says his olde worlde scales have a 1.9mm slot! Maybe I need to be a lot more generous with the slot width.