Last modified: 2024-08-26 13:44:07

< 2024-08-24 2024-08-26 >The new anchor didn't help. Same as the old one, it loses energy with every oscillation.

So we're saying there is too much energy lost in:

A normal anniversary clock has the balance wheel suspended by the spring, so there is no friction in the pivots. And the spring is a real spring, so it doesn't lose so much energy when coiling and uncoiling.

It looks like it needs to move as far as +/- 90 degrees before the spring tension is enough to unlock the anchor. And then we only add 7 degrees to the spring centre position.

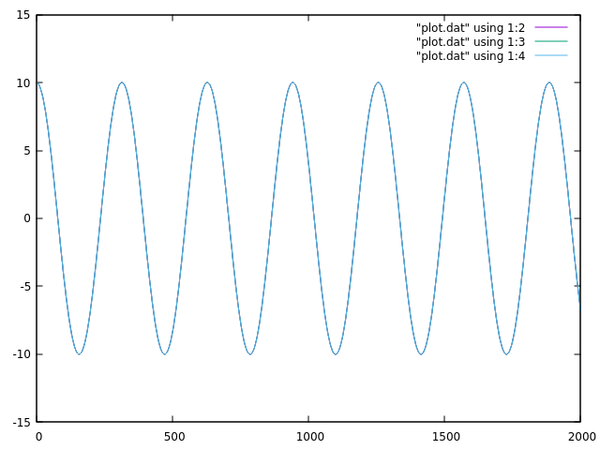

Here's the same plot from yesterday, but this time it needs to more 13x as far as the centre point offset before the centre point moves (e.g. it needs to move to +90 before the centre point moves to +7).

So it basically adds no energy at all, and if you waste some energy on unlocking the anchor every cycle then of course you're losing energy.

So we either need to make the anchor unlock with less force, or increase the stiffness of the spring (and probably increase the mass of the balance wheel as well). Either of those would make it unlock the escapement, and therefore move the spring centre point, earlier in the cycle.

OK, update: I got it wrong. My simulation wasn't moving far enough to go 13x as far as the centre point offset.

After I fixed that, I got this:

Which is now showing that it loses energy regardless of which way you move the centre, compared to not losing energy if you leave it where it is.

I'm calling "13x" the k value, I could do a plot showing how much energy is left after N cycles with different values of k.

Hmm, not looking so good:

It looks like the starting point is we gain some amount of energy roughly proportional to the amount that the centre point moves, but as k gets higher we just lose more energy linearly.

But, again: if the idea is fundamentally unsound, why do normal anniversary clocks work?

In a normal anniversary clock the spring is fixed to the frame at the top, and then the fork is on the spring near the top, and the balance wheel is at the bottom.

In my design the spring isn't fixed anywhere, it's just attached to the anchor (fork) at one end, and to the balance wheel at the other. Does that make a difference?

It means the normal anniversary clock has some reaction force from the frame, through a short length of spring, trying to push the lever, whereas I only have reaction from the wheel, through the entire spring?

In the normal anniversary clock you basically have 2 springs. One spring between the anchor and the balance wheel (like I have), and another spring pulling the anchor back to the centre point. Maybe I could try adding a second spring to my design.

I'm going to make a start on the aluminium surface. It needs:

I'm thinking I do the counterbores one-by-one with a FreeCAD Path Helix job that will just do one counterbore at X0Y0, and then jog to the location of each hole. Then I surface the top with either FaceMill or PocketShape, and then think about how to do the drilling, then take the aluminium plate off, tap the threads, and put it back on?

First helix worked, but was a bit "crunchy", I think perhaps it needs to be climb milling and it is doing conventional? I'll reverse that for the next one.

Seems maybe slightly better, not sure.

All 5 mounting holes counterbored and bolted down properly now, good.

Now do I surface the top with the single-flute 6mm tool or try out the fly cutter?

I think maybe try the fly cutter another time, stick to the 6mm tool for this because I know it will work.

I did quite a few passes because it kept leaving small ridges, I think the spindle tram could do with improvement after all. In the end I did 1.5mm steps, at 10000 rpm and 3000 mm/min, seems OK for now.

< 2024-08-24 2024-08-26 >