Last modified: 2024-06-29 13:20:53

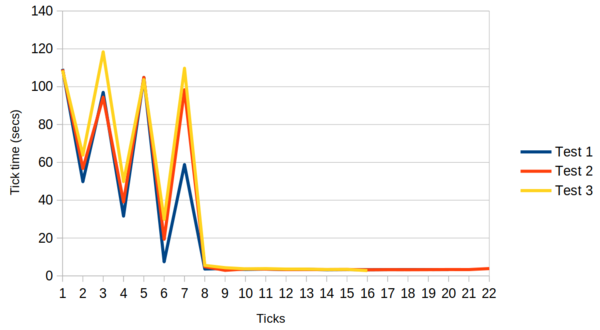

< 2024-06-27 2024-07-06 >I measured the time taken for ticks of the twisty-thread balance wheel.

I measured a datapoint every time the lever flicked across, i.e. every time the balance wheel crossed the centre position.

For the 3rd test I really tried to add more energy to the system at the start, but it doesn't seem to have made a lot of difference.

From that, and the fact that the thing is wildly out of beat for no obvious reason, I am inferring that the bearing is actually having a big impact.

All 3 tests started off in the same direction. The first datapoint is the time taken from crossing the centre point after the initial wind up, in the anti-clockwise direction as viewed from above, to crossing the centre again in the clock wise direction.

It looks like the clockwise move always takes energy out of the system and the anti-clockwise move adds some energy back.

To cancel out the beat error, here I have added 2 consecutive ticks together, to measure the period of a complete cycle:

You can see it drops quite quickly, which suggests a lot of energy is being lost somewhere. Obvious candidates are friction in the bearing, friction in the thread, air resistance.

So for the next test I definitely want the thread suspended from a hook above the bearing, so that the bearing has no weight on it. And maybe I want to take off the seals and try to dissolve the grease out, to reduce friction.

Also the thread had a knot in it in the active part, that is getting twisted up, I should slide the thread around so that the knot is not interfering with the twisting.

I did find that the period was actually very consistent at about 6.6 seconds once it lost energy to the point that the thread was no longer touching itself while twisting, so perhaps that suggests that most of the energy is being lost in twisting the thread, rather than in the bearing? Maybe we'd be better off with some fine fishing line instead of a cotton thread.

Also, maybe the reason for the beat error is that the thread is much happier twisting one way than the other?

< 2024-06-27 2024-07-06 >