Last modified: 2024-03-24 14:55:20

< 2024-03-23 2024-03-25 >Same as yesterday: CAM & machining for first side for each of the remaining pieces that I can, then once I'm done with that I can set up a square on the machine for indexing the second sides and do the second-side machining. And once I'm done with that I can consider how to make the uprights.

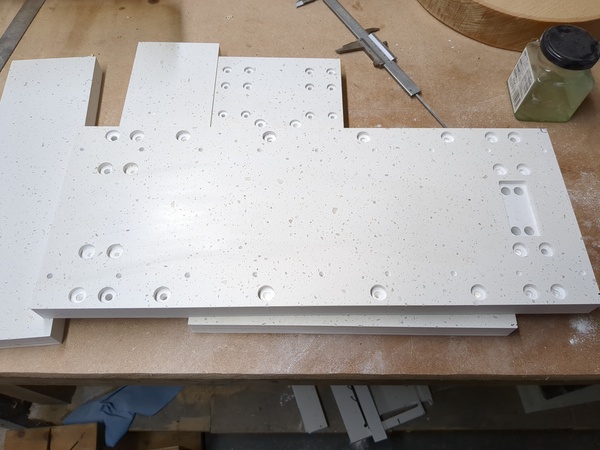

Gantry done, looks good:

Now the base pieces.

These might be slightly tricky because they're almost at the limit of what I can cut on the X axis, so need to position the material carefully. And actually I might be able to fit the material for the uprights on the machine as well, even though I can't cut both uprights in a single setup, I'll just have to position the material and cut the first one, then move the material and cut the second.

Got both base pieces done, plus the X carriage cut out of the middle of the lower base piece.

I discovered that my counter-bores are not all the right depth! Because the Helix operation in FreeCAD makes all the helixes go down to the same depth, so I think all the counter-bores go down to the depth of the shallowest counter-bore on that part. Might be fine.

Next time: try to make the uprights, then move on to second-side machining, then glue in threaded inserts, then assembly!

< 2024-03-23 2024-03-25 >