Last modified: 2024-04-03 19:39:11

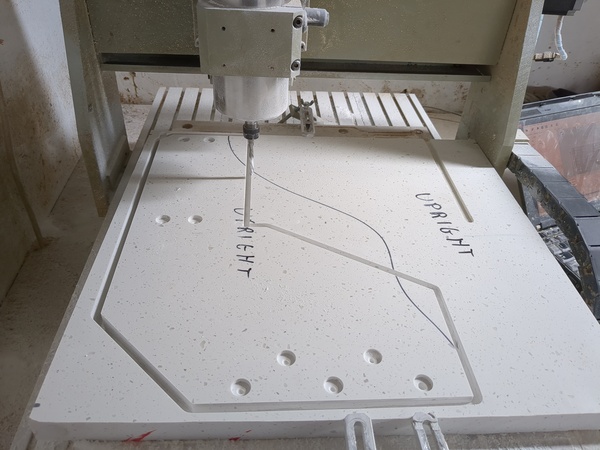

< 2024-03-24 2024-04-08 >Great success, cutting out the gantry parts works as I hoped:

Look how close the material is to the right-hand upright of the router!

Now just 3 more like this (2 with no counter-bores, one with counter-bores on the opposite side).

Just realised I left a radius on the inside corner, I will need to clean that one up with a file, and probably modify the CAD for the others to put a dog-bone type thing in.

For doing the right-side gantry parts I'm tempted to just invert the Y axis in Grbl. What could go wrong? We'd switch from climb to conventional cutting and vice versa, but I'm not sure I care.

Actually, I noticed the deflection around the outer profile is quite large in places (maybe 1mm), and is pushing away from the part - would that be reversed if I cut in the other direction? So it would deflect into my final part, ruining it? Maybe safer just to re-do the CAM with the part facing the other way.

All 4 uprights done!

So next jobs are:

In making these parts I've been repeatedly annoyed by the UGS bug where a continuous jog comes to a stop when you release the button, but then starts up again on its own. I never lost a coordinate system that way, but if I wasn't paying attention I would have done. Need to start using Pugsender.

< 2024-03-24 2024-04-08 >