Last modified: 2023-11-15 20:58:48

< 2023-11-14 2023-11-16 >First job: make a better spring, out of the piano wire.

It is way too hard to install these springs in the collets. I'm going to look up how normal watches do it and try something closer to that. Oh, maybe an assortment of tapered brass pins would be handy. Though maybe I'd need a tapered reamer as well.

I'm browsing on "Cousins UK" and there is some quite interesting stuff, including:

I'm getting the hairspring assortment and a set of tapered pins. It's probably that this stuff will all be too big for the watch, but at least might be useful for larger models.

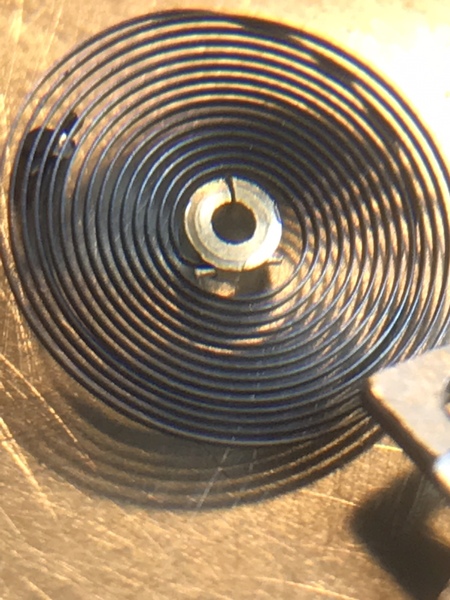

I found this picture:

Definitely looks like the spring is pinned into the collet.

I've stuck it in the side of the collet by heating with a soldering iron:

I'm trying to coil it up now. I could really do with those 3-pronged pliers from yesterday, spring-loaded please.

Could I 3d-print a forming tool that would slip over the Lindstrom pliers?

Maybe?

56 minutes with 0.25mm nozzle, or 12 minutes with 0.6mm nozzle. I'll time how long it takes to change the nozzle.

Starting at 6:24:30. Finished 6:26:58. So if the tools are already next to the printer it takes about 2m30s to change the nozzle. Not bad. I noticed if you remove the nozzle while it's only at 120 deg. C or so, the plastic comes off much more cleanly, instead of staying stuck to the inside of the nozzle.

Also, it's worth pre-heating the bed while changing the nozzle so that you don't have to wait for it to heat once you've changed it.

Maybe!

Pretty decent:

This tool works really well. So much easier than trying to use 2 pairs of pliers. I might have put too many coils on this spring, but I can always shortern it if necessary. Let's try and install it and see how it ticks.

Yeah, I reckon too many turns, it is way too weak. Also the amplitude is still pretty low. Not enough to lock properly. If I pull on the string harder it just stalls on the lock. So, let's take 1 turn off the spring.

Maybe locking is too ambitious. Maybe I should make it "dead-beat" instead of lock, and then it can cope with a wider range of amplitudes? Although, maybe the lock is required if the lever is able to detach.

Oh, actually, maybe I have worked out why it keeps stopping:

At this point, both pallets are in contact simultaneously! How has this happened? Did I blunder the scaling? Or is it just broken? This is just as it is unlocking the discharging pallet.

Ugh, the problem exists in CAD too:

How did I miss this?

First check is to overlay & scale the metal-escapement-2 version of the pallet fork in Gimp and see if all the holes line up.

Yes, looks like they line up:

So the metal escapement was never going to work very well either, and it is a miracle that the previous plastic version did!

I also think part of it is due to poor tolerances. Because if you look at the screenshot and imagine the escape wheel is trying to turn clockwise, it could actually work fine. It is moving clear of the entry pallet and providing impulse to the discharging pallet. It just has zero clearance.

So one problem is I need to modify something about the escapement to give it more clearance.

The other thing is: how long would I expect the balance wheel to keep swinging back and forth if the pallet fork is removed? I think Harrison said 10 minutes in "Concerning Such Mechanism". Mine swings for about 5 seconds. I can see the spring is rubbing against the frame a bit, can try and fix that.

Tweaking the spring and oiling the pivots (but... lol, I think this has no effect) has got it up to 10 seconds.

I'm going to take another turn off the spring and see what happens. It might stop quicker because the spring restores it to the centre more strongly, or because it will run faster which will make it experience more friction, or it might stop slower because it has more stored energy.

Maybe spins for 11 or 12 seconds, maybe no different.

I set it going with a bit more weight (this time the room spray bottle plus the colourful allen keys) and it actually goes really well... interspersed with going really poorly. At times it exhibits amplitudes in excess of 180 degrees, which is very satisfying. It is obviously working well when it does this, the escapement locks nicely, the balance swings freely, etc. But then the amplitude drops almost to nothing, and it sometimes stalls.

Things I noticed:

Do the teeth always skip at the same place relative to peak amplitude? If so, this would suggest that both the drop in amplitude & the skipping teeth are both caused by eccentricity of the escape wheel.

I should have marked the barrel and the escape wheel so that I could tell if effects were synchronised with one or the other. I can do that by counting teeth in a pinch.

I recorded a video, timestamps for reference:

At 00:26:06, the balance wheel has only swung to about 45 degrees. This means the cause of the failed lock was before this, i.e. it didn't get enough impulse, or it lost too much energy.

So the next good lock is 7 teeth later, and the next failed lock is another 7 teeth after that! That's close enough to 13 that I would suspect it is sync'd with the escape wheel rotation. If I spin the escape wheel on its own, can I see any run-out in its teeth? Yes, looks like maybe 1mm difference between high and low.

Measuring with the Vernier caliper from the opposite side of the shaft to the tips of the teeth, I measure a range from 20.8mm to 21.5mm. It is visibly crooked. I think reprint this part and try to put it on square.

Actually, before that, I heated it up with a lighter and squared it up a bit. It looks a bit better now. Maybe. Let's see how it runs. Much better! But still not adequate.

I think the property where the pallet pin lands on the corner of the tooth instead of squarely on the locking face is a bug. I will try and modify the pallet fork so that at the point of leaving the impulse face on one pallet, it lands on the locking face of the other pallet.

Well, this was a lot of work:

I still don't know the best way to constrain the sketch with the layout of the pallets so that it acts symmetrically. I'll print it and give it a go, it doesn't obviously look like it's going to make a lot of difference though.

I reckon it works a bit better, not really clear. I think the problem might be that the balance wheel spends too much time unlocking the escapement compared to receiving impulse. Maybe I increase the "base circle" of the escape wheel, so that the locking face gets shorter?

I recorded a new video clip to measure how much amplitude is spent on each phase of movement:

From a total swing of 275 degrees, it spent approximately:

(Also, at these high amplitudes, it does unlock the escapement again a bit towards the end of the swing. But that's not my biggest issue at the moment, and it can easily be solved by widening the slot.)

So this is msotly good! It spends almost the entire time free of the escapement, the only issue is that it spends almost twice as long unlocking the escapement as receiving impulse, which naively sounds like it is wasting more energy than it is gaining. Obviously not the case because it does run, but let's try and reduce the amount of time spent on unlocking, by making the base circle of the escape wheel larger and leaving everything else alone.

The length of the flat portion of the locking face was previously about 0.95mm, I'll reduce it to 0.5mm.

Also, I can repeat the measurement of how many degrees it spends on each phase, but in CAD, to see if it matches reality...

So that is pretty close, given that I had to measure the video to the precision of 1 frame. So that's encouraging.

And now let's repeat the measurement in CAD using the new escape wheel.

The new escape wheel is also going to need a new pallet fork, because it only moves by about +/- 9 degrees instead of 11 now, so the slot is not wide enough.

With the new escape wheel, it is free for an extra 15 degrees, and unlocking for 15 degrees less. So now, with a swing of 275 degrees, starting from max. clockwise position:

Oh, and does it behave the same on the reverse swing? i.e. starting from the position that ended at and returning to max. clockwise? We get:

So, yeah, not symmetrical, and still spending more time on unlocking than on impulse, and in this direction it is even worse.

Note we don't necessarily want to maximise the amount of impulse it receives. I think we would prefer to keep the total impulse as small as possible, and deliver it all at exactly the 0 degrees position. And similarly we would prefer to keep the unlocking force as small as possible, and deliver it all at exactly 0 degrees.

I'm tempted to print the new escape wheel with the 0.25mm nozzle. Not the pallet fork because that's too big, so let's widen the slot in the pallet fork, print the pallet fork with 0.6mm, then print the new escape wheel with 0.25mm.

Fuck, FreeCAD segfaulted while I was doing that, so frustrating. Try again after lunch. Also, why is the file picker so slow in FreeCAD?

New pallet fork and escape wheel:

Well the new pallet fork and escape wheel do work better I'd say. When running with just the room spray bottle for a weight, it runs continuously with no stalling and very consistent. The amplitude is quite low but it is just enough for it to mostly lock properly.

When I add more weight the amplitude goes up, but then it sometimes stalls at the unlocking.

I think I'll record it running for reference, then take another half turn or so off the hairspring. It's the ~15:50 video.

OK, yeah, making the spring stiffer has helped, and now running it with the spray bottle + allen keys gets really good amplitude: https://www.youtube.com/watch?v=NW2_8KEqEEE

I have noticed that the impulse pin sort of rubs against the underside of the top of the slot when it's in the upper half, and is miles away from the bottom of the slot in the lower half. Are the banking angles not equal about 0? Or something else is wrong? Check the banking angles in CAD.

It banks at the entry pallet at 9.5 degrees, and at the exit pallet at 9 degrees. Does 0.5 degrees make that much difference?

Errr... CAD has it rubbing against the slot when banked against the exit pallet:

Lol, and also rubbing against the slot when banked the other way, albeit not as badly.

So the real question is why isn't the real version rubbing against the slot at the bottom as well? Not sure.

It takes about 24 seconds for one revolution of the escape wheel, and that's geared down from the weight by a factor of 6.25, so 150 seconds for one revolution of the barrel. In the actual watch the mainspring will do one revolution per hour, which is 24x this, so would need (more than, because of losses) 24x as much torque on the mainspring as we currently have on the barrel. In that clip I was using about 570g, and the barrel radius is 10mm, so that is 0.057 Nm, so the watch would need (more than) 0.057 * 24 = 1.37 Nm of torque.

This forum thread discusses watch mainsprings with torque varying from about 10 to 20 Nmm, which means mine requires about 70x more. Not good! Although tbh not actually as bad as I thought it might be.

Err... the watch mainspring will do one revolution per 12 hours. So it will need 12 * 1.37 = 16.44 Nm of torque, or about 840x the watches from the forum thread. Great. So it definitely needs to be more efficient. I guess I'm kind of hoping that just making it smaller and metal will give me that for free, but maybe that is too naive.

Next steps on the watch project:

I had some trouble finding transformers that give me less than 6v. It was much easier to find 28BYJ-48 stepper motor variants that want more than 5v, so I've done that instead. It came to £50.04 inc. VAT on DigiKey for 3 lots of stepper motor, capacitor, and transformer. Just need cables/plugs and I think I have everything else already.

I'll skip the CAD changes until after the stuff arrives, that way the CAD will be fresh in my mind when I come to make the parts.

< 2023-11-14 2023-11-16 >