Last modified: 2023-10-22 20:13:56

< 2023-10-21 2023-10-23 >I've generated all of the STL files for Boggle letters, with 15mm * 15mm cylinder cutout (works out to 12mm at 80% scale).

I think the eSun PLA+ will arrive later today, so I should be able to start the new base printing today.

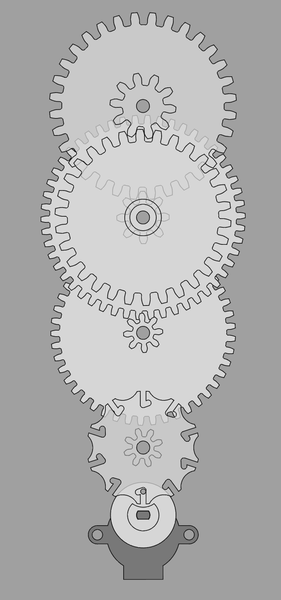

I swapped the second and third wheel back, to make clearance between the second wheel and the third wheel's shaft.

This then meant that the counter-wheel's shaft interfered with the third wheel, so I increased the module of the counter-wheel stuff to 2.1. And now all looks good:

Next up: a mechanism for setting the hands. I think I want a magnetic connection between the second wheel and its pinion. So that needs to be split into 2 bodies, and then one wants a steel washer and one wants magnets.

The pinion has a step in it that will locate inside a steel washer, the gear has a step for that washer to sit inside, and 3 holes for 8mm * 2mm magnets. From testing by hand, it doesn't feel like there's a lot of friction between the washer and the magnet, so even with 3 magnets I may need to rough up the surface of the washer. It would be very silly if the clock keeps poor time because of the magnets slipping!

Next up: crossing-out.

Lol, just noticed the second wheel no longer engages with the Geneva-driven wheel, obviously. Fixed that.

Something like this??

I noticed the stub on the hour wheel was 14mm not 12mm, needs to be 12mm to fit in the 6701 bearing. Fixed that.

I think I want the shafts to be supported by a thick back plate and no front plate, so that the gears can be seen clearly. Wonder how much trouble that is. Maybe I could make some bearing blocks that have 2 of the small bearings in, and screw these blocks into the back board.

If I make the shafts out of 6mm rod then they can seat up against the front bearing, and I'll just need a collar or cross-pin or something on the back to keep them from falling out. Oh, might also need something on the front to stop the wheels from coming off the shafts.

Most of the gears can safely slip on their shafts. The second wheel pinion needs to be able to slip in order to set the hands. But the third wheel needs to not slip else it won't drive the minute hand. Maybe I machine a flat on that shaft??

Here's a bearing block:

Still need to:

Emma wanted to do some pumpkin carving, and I had the idea to rotary-carve a wooden pumpkin, so I'm doing it. I got the model from https://www.printables.com/model/28400-pumpkin/files

I scaled it down, and squished it a bit to make it a short fat one, and I'm making it out of a piece of random wood that the conservatory roofing was delivered on. With Meshmill obviously. My phone battery is flat but I took this picture before it died:

And this is after it was done:

I'm kind of disappointed with it because the segments aren't really very obvious. It looks more like a badly-made sphere than a pumpkin.

Emma painted it orange:

< 2023-10-21 2023-10-23 >