Last modified: 2023-10-06 16:00:41

< 2023-10-05 2023-10-07 >https://www.temujin.ai/CAM is a web-based CAM tool that makes CNC CAM as easy as 3d print slicing.

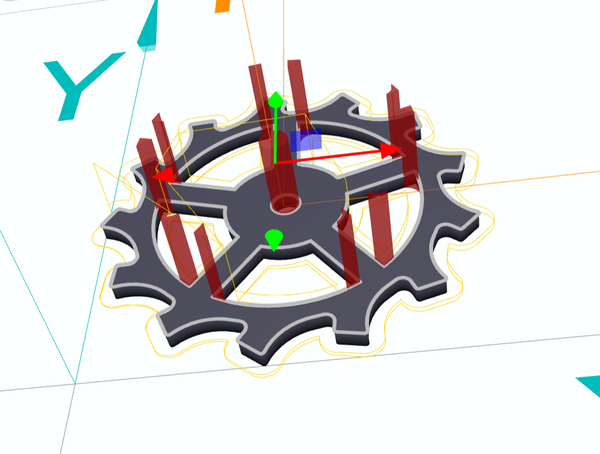

It even gives you a visualisation of the material "left behind" in the corners:

However it does think a 1mm tool can get all the way into the 0.3mm radius at the root of the teeth.

Also it's not actually open source, so maybe not to be trusted.

It ramps the cut though, which FreeCAD doesn't, and it seems to all run in JavaScript so maybe worth taking a local copy of this. And the code isn't minified!

I downloaded it with "Save Page As..." but it doesn't work.

First problem: it loads some stuff with crossorigin="anonymous", just deleted that.

Second problem: some of the JavaScript files are "modules", which result in Cross-Origin errors when loaded from local filesystem, even though it's the same origin. Is this deliberate or just not tested properly?

Looks like it is deliberate: https://github.com/whatwg/html/issues/1888 and https://github.com/whatwg/html/issues/8121

8121 suggests:

We have to spam <script> tags from <script src="./least_dependent.js"></script> to <script src="./most_dependent.js"> </script> rinse and repeat for however many libraries or extra program files we have, then we can finally do <script src="main.js"></script>.

OK, so will this work? No, I don't think so. I think you have to change everything to not use import syntax as well.

I think I just have to suck it up and run SimpleHTTPServer.

Now the problem is that "Save Page As..." didn't save all the files that were imported. Such fun.

I manually downloaded the rest with wget, but now it has the issue that half of the stuff refers to Temujin_CAM/files/ and half of

it refers to static/js/. I'm going to ditch the "Save Page As..." version and get them all manually. Probably once I

have it working I want a script to automatically download the latest version so that I can stay up to date.

Changes I want to make:

POSTsUpdate: actually I think all the toolpath generation is done by the /reach endpoint :(. Sad times, no self-hosting.

Ugh, I went looking to see if Temujin actually is open source, and now github makes 2FA mandatory. I've put the 2FA setup

key & the recovery codes in keys.

I tried to use Gnome Authenticator but it doesn't exist in Ubuntu 20.04 apt. I tried to install it from snap but it doesn't work because AppArmor blocks it from using the Gnome keyring, or something.

I'm using oathtool with oathtool -b --totp $key.

Lol, after going through all that, https://github.com/temujin is not even related.

The junction box is too small, annoying. Ordered a bigger one on Amazon.

I want to make a plate that can hold a chuck so that it points upwards. Requirements:

I have a piece of kitchen worktop offcut that might be fun to make this out of.

Actually, come to think of it, if a typical workflow involves moving the chuck between the lathe and the CNC router, then having to bolt it down to a separate plate is actually more faff than using clamps. Maybe don't bother making this.

For now I'm going to improvise a chuck mounting plate with plywood spacers and strap clamps, but it would be good to make a proper one.

Op 1: great success.

I ran this at 14000 rpm, with 150 mm/min feed rate.

Op 2: Success.

I broke the first 1mm end mill I tried, at the point where it went to do the first "finishing" pass, i.e. where it had 0.55mm depth of cut. I reduced feed rate to 40 mm/min, at 24000 rpm, and it completed OK. I think this feed rate was probably too low because the chips were very "dusty" and it left quite a burr, but it worked.

So next up is trying to use the 0.6mm fibreglass-cutting end mill. The plan is to have very low depth of cut and width of cut, and low feed rate, so as not to break it. But first: how much material is left in the roots of the teeth?

0.1361 mm left to go. So if the first lap has "stock to leave" of 0.1361 mm, then it won't cut anything. 0.1361mm is not a lot, so it's not a million miles away from being able to just leave as is. Would be good to try the other tool though. If I can't get the other tool to work then I'll just make it again but stop after the 1mm end mill. While I'm at it I may as well try to tidy up the corners in the crossing-out, but only after the teeth.

Using 0.1mm depth of cut.

Op 3: Cocked up.

You can kind of see that the teeth on left of pic are closer to the crossing-out than those on the right.

I lost the coordinate system and had to manually re-centre on the bore, and obviously didn't get it close enough.

But at least the 0.6mm tool didn't break! I ran it at 40 mm/min with 0.1mm depth of cut, 0.1mm maximum width of cut, and 24000 rpm. It seems to have a pointy end so I must remember to run it a bit deeper than the flat-ended tools.

I parted off with the lathe:

Sanded with the plywood sandpaper, and polished with autosol:

But at least I now know how to make this part! Just need to do it again and not fuck up the coordinate system. It ended up about 0.7mm thick, so I should have done more sanding before polishing it.

And I can use the same technique (machine on the end of round bar, part off later) for lots of other parts.

https://www.youtube.com/watch?v=LPaPfc_RRQM

I'm not sure if I should keep making the thin brass parts while I have the workflow in my mind, or whether I should try to make the shaft for the escape wheel first so I can see it spinning in the frame.

< 2023-10-05 2023-10-07 >