Last modified: 2023-09-18 16:19:31

< 2023-09-02 2023-09-04 >Made a minimal testcase to show my issue with Matter.js and reported on github: https://github.com/liabru/matter-js/issues/1240 https://incoherency.co.uk/matterjs-test-case/

But actually, having made that test case, maybe that is an easier place to construct a model of the pallets, and then when I get it to work without the erratic movements I can just copy it back to the main simulator project.

I revisited this in the afternoon and did manage to find a solution: https://incoherency.co.uk/matterjs-test-case/fixed.html

I needed to make the two balls be separate bodies and constrain them with constraints, instead of trying to make one compound body. Seems like it's a bug in compound bodies, but never mind.

Last night I was thinking about making the pinions for the watch, and I'm not really sure how I'm going to hold the shafts on the 4th axis, far enough away from the chuck that my gear cutter can reach them without hitting the chuck. Maybe I need like a "steady-rest" behind it to react the cutting forces, and then I can have it sticking out a long way without worrying about bending it.

Problems still unsolved on the watch project:

pivot polishing

4th-axis concentricity

cutting pinions

making the pivots in the plates

designing an escapement

cutting the internal teeth on the barrel

affixing the mainspring to the barrel

affixing the hairspring to the plate and balance wheel

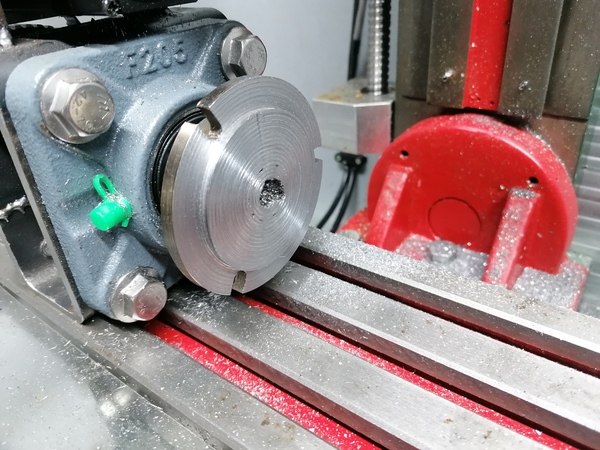

Let's go and look at re-cutting the register on the 4th axis...

Well I think I made an improvement.

It was clearly cutting slightly out-of-concentric with what was already there, which is good. I had to cut down the front face because the protrusion ended up too long for the chuck to fit over it. It feels slightly looser than it did before, but I can't exactly feel play. Maybe there is <0.1mm of play, but that's better than no play and 0.3mm of error. Will have to see how it goes.

Printed a bracket to mount the binocular microscope on the lathe carriage.

Looks like a great success so far. I may need to remake the bracket in a stiffer material if it proves too wobbly. Getting the image in focus requires moving the microscope all the way to the limit of its travel, so maybe a taller bracket would be a good idea too.

Also might be better if it angled towards me a bit, instead of having to stand directly over the lathe.

Parallel-axis verge and foliot

Having fixed the pallet model in Matter.js, I fiddled with the escapement simulator a bit.

I discovered this configuration:

It seems to act like a verge and foliot but without the requirement for intersecting axes. The impulse faces alternately push the pallets one way and then the other. If this idea works reliably then it would obviate the need for a hairspring (although a hairspring would obviously improve accuracy).

The main reason not to favour a verge and foliot for my own watch is the size and complexity of the perpendicular axis, so this could be a real winner.

I don't know if there is any precedent for a parallel-axis verge-and-foliot type escapement, every example I can find has the verge perpendicular to the foliot.

Slightly more reliable:

And note that both of these are using code around c34ce68776bfdc3266a5e12e9a4e562c74e6eaf4 which has bugs related to banking angle and impulse face angle!

Come to think of it, this escapement is just an ordinary recoil escapement, except the pallets are made of pins.

The anchor escapement was invented in 1657, but pocket watches were still using verges until the mid 1800s. Why didn't they just put an anchor on the foliot? Is it because you can't get enough amplitude?

There aren't that many examples I can find of clocks that have balance wheels but an escapement other than a lever escapement or a verge. Brian Law has this, with gravity escapement: https://www.youtube.com/watch?v=DehSYhBEnDQ (he also made a full clock with same: https://www.youtube.com/watch?v=CsBXfaWNS84 )

I also can't find an example of a recoil escapement where the pallets are simple pins.

The main issues with using a "foliot and anchor" are:

low amplitude, because the pins need to clear and catch the teeth

all the energy in the foliot is removed and restored on every tick, so needs a lot of power, which will wear the pivots

not isochronous, so will run slower as the spring runs down, and as temperature changes and as the watch wears

I should add a "scope" view to the escapement tool like the one on the oscillating engine tool, so that I can actually plot things like amplitude, recoil, beat error, period.

One option to improve the amplitude would be to put the anchor on a "crutch", although once you take that step you're getting a bit close to "lever escapement" territory. Reducing the number of pivots should be taken seriously. Maybe when I get to prototyping I can try both options and see if the amplitude is worth the complexity.

At module 0.2, I have 156 teeth on the barrel, which need to pass in 12 hours. So we pass 13 teeth per hour.

We need to gear this up to 5000 escape wheel teeth per hour, which is a factor of 384. 3 lots of a factor of 8 would be more than enough.

If the escape pinion has 7 teeth, and the escape wheel has 20 teeth, then that leaves a factor of 134 for the rest of the train. 3 lots of a factor of 5.5 would be more than enough.

barrel turns 13 teeth per hour. This turns the first wheel which has 5.5x as many teeth on its outer, so the first wheel passes 71.5 teeth per hour. Thus turns the second wheel with the same setup, so the second wheel passes 393.25 teeth per hour, which turns the third wheel with the same setup, so the third wheel passes 2162.875 teeth per hour, which turns the escape pinion, so we get 6179 escape wheel teeth per hour.

If we wanted to lose a wheel, then instead of 7:36 on three wheels, we could have 7:81 gearing on just two wheels. Ah, but then the first wheel will extend beyond the bounds of the barrel. Probably stick to three wheels in the train, plus barrel, plus escape wheel.

< 2023-09-02 2023-09-04 >