Last modified: 2023-09-04 20:12:05

< 2023-09-03 2023-09-05 >I've added some springs to pull the anchor towards the centre position, and configurable mass on the anchor - it's effectively now a balance wheel, although not rendered as such.

Next steps are:

How much torque can I actually get out of the mainspring?

How much torque do I require at the escapement?

Will it be too powerful for me to be able to wind it up?

How much variation in torque is there between fully wound and empty?

How far away from isochronous is the "pallet pins directly on balance wheel" escapement?

Can I make module 0.2 gears?

Can I make pivots smaller than 0.5mm?

How can I polish pivots?

Do I need to "cold-forge" the plates? How do I tell whether cold-forging has worked?

Do I need to burnish the pivot holes? How do I tell whether burnishing has worked?

I tried to add a balance wheel to the escapement simulator but it makes it behave weirdly. It seems like constraining the pallet pin to a wheel that can rotate around its centre acts very differently to constraining the pallet pin to have a fixed distance from that wheel's centre. Even though they mean the same thing. Maybe I kind of give up on Matter.js after all.

This evening I want to design a 3d-printable model of the "pallet pins directly on balance wheel" escapement (I should come up with a better name for it). And tomorrow hopefully I can try it out in between roofing. It should have support for adjustable weights on the balance wheel and adjustable springs. It probably wants to stand vertically (screw it to a piece of wood), so that I can drive it with a weight on a string. And I want to try to use pivots made of steel wire, running in tapered holes.

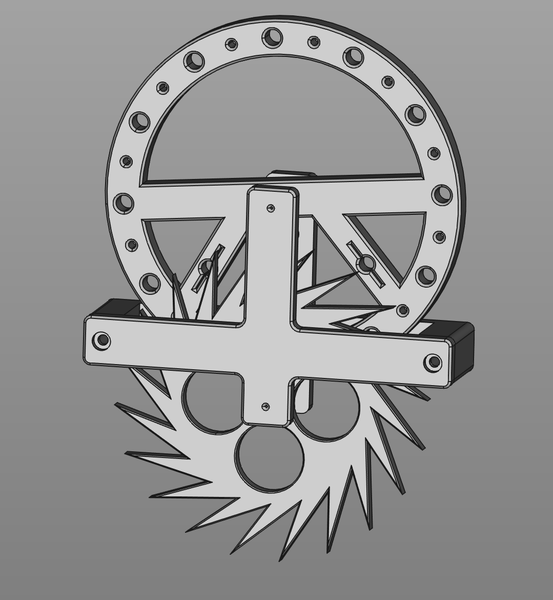

I took the parameters from the simulator into FreeCAD and modelled this:

It will get screwed to a piece of wood. 2x 6mm metal rods will form the pins. I'll wrap a bit of a string around the escape wheel shaft and power it with a weight. Sadly it is too big to print in one go, so I'm just printing the balance wheel for now, and will have to do the plates and the escape wheel separately.

It's designed to use my 1.75mm stainless wire as pivots, and I'll use the tapered ball end mill as a taper reamer to open up the holes in the frame. Not really necessary for this demo but good to get some experience of making tapered pivot holes.

I can add some screws into the wood and attach springs to the balance wheel to see what difference they make. This might be easier to experiment with than the simulator is.

< 2023-09-03 2023-09-05 >