Last modified: 2024-12-07 16:16:19

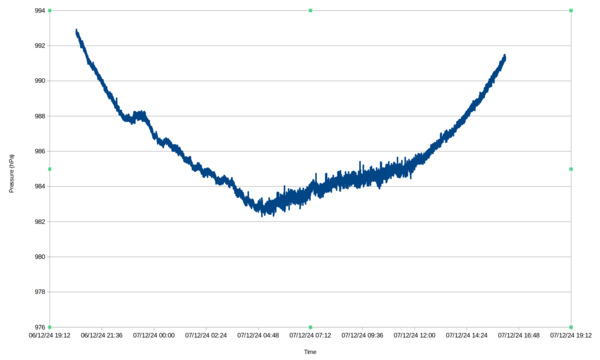

< 2024-12-06 2024-12-08 >This is the plot of pressure over time:

Reached a minimum of about 983 hPa at about 4.45am. Not sure why there is more jitter between the minimum and midday. Wind??

The wind blew down some of the fences in the night, annoying.

And twice as many weight nuts, modulo the allen key.

The frame is noticeably splayed apart but it still seems to run so I'll just see how it goes for 3 (?) hours. The balance pivots are very loose.

Aargh, I accidentally refreshed the clockwatcher page and lost all the data. I rewound it and started it again.

Definitely need to work on storing the data persistently.

I don't know what happened just before 1000 seconds. Best guess is that the drive weight is too marginal and the remontoire didn't rewind, but then at 1150 seconds or so it did.

At about 10500 seconds I came back to the office and noticed that the slotted disc was intermittently scraping the encoder housing. It's not obvious that it has made a significant difference to how the clock runs though. I speculate that it is caused by the drive weight moving further back and increasing the torque that is splaying the frame open.

It stopped after about 11000 seconds (just over 3 hours), the remontoire having failed to rewind.

Non-averaged:

Averaged:

From about 5000 seconds onwards, there was a gradual decrease in amplitude and increase in period. Is this when the slotted disc started rubbing?

I think I'd want to re-adjust the balance pivots to accommodate the extra weight, add maybe 1 more nut to make sure the remontoire always rewinds, and make sure it is not rubbing the slotted disc.

I'm going to ask Cursor what to do about the position and velocity data getting out of sync.

Actually I think I'm wrong about it getting out of sync. It looks like addReading()

always adds a velocity value if it added a position value, so I don't see why they'd get

out of sync.

And in fact I can see the velocity plot kind of pulsating, but although the timestamps on the x axis are scrolling from right to left, the data in the plot is staying basically still.

Meh, this is too annoying, and I don't even really care about this plot. I'll just delete the plot.

I am going to concatenate the 3 PDFs into one, and then get some quotes for printing as a book.

$ pdfunite 1.pdf 2.pdf 3.pdf output.pdf

And my OCD requires me to edit out the text "Printed by Copytech (UK) Ltd".

I tried opening it in LibreOffice Draw, but it messed up all the formatting.

Inkscape loads it up successfully. I can't easily edit the text, but I can draw a white rectangle over it. The export tool can't save as PDF, but I can "Print to file" to get a PDF.

It seems like the "print to file" tool in the Inkscape snap doesn't have permission to save to a file. I can't find anywhere that it does have permission to write to. (Update: it is just slow; the files did arrive eventually).

Apparently you have to use "Save a copy" to export a PDF, that has worked.

But somehow the Inkscape-exported one is 100 megabytes instead of 3 megabytes. I'll use the Adobe tool to shrink it.

Lol, only reduced it to 84 megabytes, oh well. But the image quality is ruined.

Seems like you should be able to draw a rectangle over a PDF without really changing it at all.

Next up is the Adobe "Sign your PDF" tool. ChatGPT says you can use that to draw boxes over things. Adobe want me to sign in with Apple or Google, no thanks.

Apparently "Okular" has a way to redact information from a PDF, let's try that.

It draws your "highlight" behind the text, but making a black highlight is good enough to redact it.

Good, that's done the job, and I now have the full book as a single PDF, with "Printed by" redacted, and it is only 12MB.

It's £23 from PrintPond, A4, black and white, bound with a "metal channel".

The boiler is having trouble meeting the target flow temperature.

The target is 60 deg. C and it is basically throttling down to minimum at 30 deg. C, so the radiators are not getting very warm.

This has been an issue in the past and I never solved it.

I think the issue is the difference between the outgoing temperature and the return temperature.

We have one radiator removed at the moment for decorating, so maybe there isn't enough flow through the system and the water is coming back still hot?

I reduced the target temperature to 45 deg. C and it seems to be doing a better job of meeting it now.

Must remember to put it back up once the removed radiator is back on.

I was thinking that instead of using conical pivots, I could have a steel wire pulled tight running from top to bottom through a hollow balance wheel, and PTFE bearings at the ends. This is similar to the balance suspension in my grandad's clock.