Last modified: 2024-10-24 12:48:46

< 2024-10-23 2024-10-25 >I'm going to CAD the "folded sheet metal" version, to see how big it ends up being. The good news is if I align the fold lines with the X axis then the centre of mass doesn't move in X when I fold them up. So I can get FreeCAD to tell me the location of the centre of mass, and I know it needs to line up with the origin.

Also, I can try moving the coins closer to the pivot, but making the beam wider so that they're still constrained, and see which direction that moves the centre of mass. It might be better to overlap the coins more even though it will require a wider beam, if the shorter beam means the centre of mass moves in.

First impression is that increasing the width doesn't change it by much, but moving the coins closer to the pivot makes a big difference. So we would prefer to make the beam wider and move the coins closer.

FreeCAD keeps segfaulting, very frustrating. https://github.com/FreeCAD/FreeCAD/issues/17447

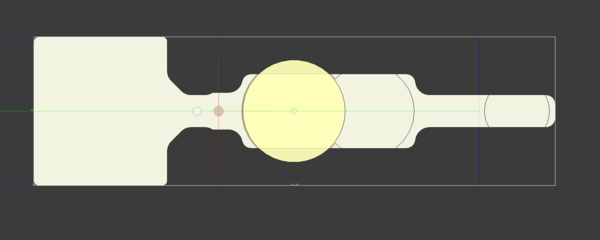

Something like this could work:

And they tessellate like this:

So there is room for 14 of them on the table, with gaps big enough for a 6mm tool to get through.

And actually if we tile them this way then there is room for 16:

Although then there is not a lot of room for bolts to clamp the plate down.

So I'm imagining:

I'm going to finally take the time to clean the chips off the machine, maybe tidy up the rest of the garage, check all the bolts on the machine, maybe Loctite them. And put an indicator on the spindle to see if that is where the chatter is coming from.

I hate cleaning the chips off the machine because I inevitably get tiny metal splinters in my hands. I've ordered some heavy duty nitrile gloves.

I did put an indicator on the spindle, and determined that there is about 0.15mm of free play in the Y axis. Pretty bad!

I have taken the BK12 bearing block off, and put an indicator mounted on the housing, touching the inner race of one of the bearings, and pushed the inner race from the other side, and saw about 0.1mm free play there, and I wasn't able to push very hard with just the end of my finger.

So I think this is the problem that "Piotr Fox Wysocki" https://www.youtube.com/@PiotrFoxWysocki/videos talks about in one of his videos. These bearing blocks just have 2 ball race bearings inside pushed up against each other. It is impossible to preload them unless the inner races can move closer together without touching each other.

His solution was to put a shim washer between the bearings to create space for the inner races to move in, I will do the same. Need some shim washers 28mm OD, maybe 22mm ID, 0.5mm thick? May as well do all 3.

"M20x28mm" is readily available, 0.5mm thick, I've gone for that.

In the mean time I have taken the other bearing blocks off and got them ready for installing shims, and finally tidied the rest of the garage.

< 2024-10-23 2024-10-25 >