Last modified: 2024-10-11 08:46:59

< 2024-09-28 2024-09-30 >The plan is to CAD up a new version, that will be made in one piece with integrated counterweight, as per yesterday's notes.

I'm going to draw out the rough shape I want, then do some approximate calculations of the weight/torque to calculate how big the counterweight needs to be, and iterate until it is about balanced. The counterweight wants to be left slightly heavy so that it can be reduced by drilling to make it balance.

I have some aluminium bar 20mm by 25mm.

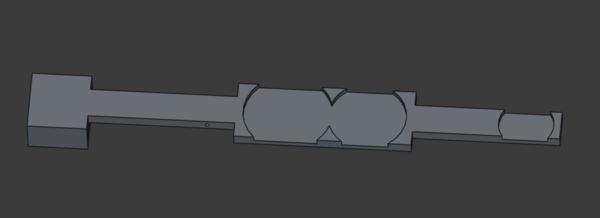

Starting from this shape:

On the right-hand side of the pivot, we have:

(I've approximated the cylinder pockets by reducing the diameter so that it looks like the amount of material removed by the cylinder is about right).

So the long thin rectangle is centred at x=88.8/2 = 44.4. And the 2 side rectangles are centred at x=7+44.7/2 = 29.4.

So now let's convert to volumes and centre positions.

We could compute a "volumetric torque" by multiplying the volumes by the distances from the pivot (which is at x=0), and then convert that to real torque by multiplying by the density of aluminium.

We could compute the distance to the centre of mass (= centre of volume) by taking the average distance from pivot, weighted by volume.

But I'm just going to multiply the volumes by the density of aluminium (about 0.0027 g/mm^3) and sum up the individual torques, in "gram millimetres".

So adding those up, the aluminium on the right hand side of the pivot exerts a torque of 244 g mm. Plus a coin of 8g at x=20, let's call it about 405 g mm that we need to balance.

On the left side of the pivot we have:

And we'll adjust the height of the counterweight to make it balance.

Volumes and centre positions are:

And then torques are:

So we have to solve:

28.2 + 25.6X = 405

25.6X = 405 - 28.2 = 376.8

X = 376.8 / 25.6 = 14.7mm

So the counterweight needs to be 14.7mm tall.

Here's an example of what it could look like:

After lunch I'll do the CAM and try and make one. Haven't quite figured out the best way to make the outline of the counterweight line up properly. Maybe I ignore it for now. Also, I still don't have a 1mm end mill, so we'll have to skip the slots.

In 20240824 I said I was using the single-flute 6mm cutter with:

I can't work out how to do a sensible facing operation, so let's just say I'll manually jog the tool around to face off the top.

Here we go:

Much better than the last one.

This is 135mm long, 16mm wide, and 18.5mm tall. The 18.5mm dimension makes it maybe too bulky to conveniently carry at a car boot sale etc., not sure. Perhaps it would be better longer and wider and thinner.

I don't have a good weight to test with (I could make a "calibration coin" of the correct weight but excess thickness, just haven't done it yet).

The most convenient thing to use for weights is small nuts, 6.7g isn't enough to move it and 8.8g tips it all the way, so I think it is within about 15% of being correctly calibrated.

For the next one:

New coolant pump installed. It wasn't very happy at first, seemed like it was stalling. I lifted it up and it managed to prime properly, and now I think it's not stalling any more. If this one stops working though I'll need to get a more powerful pump.

Here's how we're looking after top-side machining:

Y axis thrust bearing block came loose.

Probably want to slightly increase the height of the part so as not to machine vice jaws.

Tongue is too weak to be machine unsupported sticking out of the vice. I think machine bottom side first, with overhangs on both sides, machine the left-hand edge to full thickness, then use that edge as an X reference for second side. Also do a much more basic machining of the second side, just clear the material away in a cuboid, and do all the profiling from the top side, may need to hand-edit gcode.

Top/bottom alignment is very poor.

Could do with thin parallels or some other method to keep the device parallel when tipped on edge.

Breaking the edges with a stone is effective but my stone is too unwieldy, need a smaller one.

Now I need the block it sits in.

Could do with a profile around the edges of the coin slots to establish the fillets properly.

Don't know why surface finish is worse on 2nd part (because the tool got chipped?).

< 2024-09-28 2024-09-30 >