Last modified: 2024-08-30 14:04:06

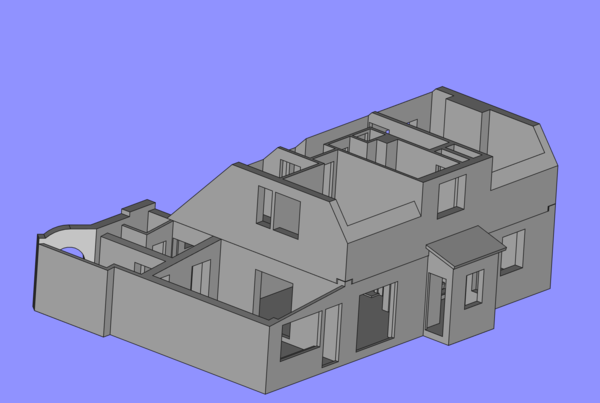

< 2024-08-29 2024-09-09 >Some progress:

Walls are now in the correct places for the first floor, and sloping rooves.

Windows and doors are just guesses, need to go back and measure them at some point. Also the wall in the cupboard thing is at a guessed position and thickness. Will be interesting to see if there is actually a void in there between the cupboard in the bedroom and the shelving in the nursery.

Now that (I think...) I've settled on using piano wire as a suspension spring with a more conventional anniversary clock escapement, I want to design a 3d-printed prototype escapement.

The frame will need to support the top of the suspension spring and hold all the gears etc., and then it'll be clamped in a vice and the balance wheel will hang underneath.

Most of the clock will be a normal deadbeat escapement, but the anchor will be linked to a lever that is clamped to the suspension spring.

Maybe I could use the "deadbeat spring" prototype, but with a lever on the anchor, and some external mechanism of suspending the balance wheel?

Either way I'll need a more convincing balance wheel than the mole grips, so I may as well make one. I noticed that the one in the video from the other day was hanging from the bottom of the suspension wire, I think that is a good way to get the centre of mass directly under the suspension point. It only seemed to be pivoted in one axis though, seems like hanging it with a U-Joint would be better. Perhaps the idea is that the flatness of the clamping part makes it perpendicular in one axis, and it only needs to pivot in the other?

I don't know how well 3d-printed parts will be able to clamp the thin wire I have. Worth a try though, if it doesn't work I can make some metal clamping parts.

The "Horolovar" website is actually quite good: http://www.thehorolovarcompany.com/

Balance wheel with hanger/clamp:

The holes around the perimeter of the balance wheel will take M12 bolts for weights.

< 2024-08-29 2024-09-09 >