Last modified: 2024-06-10 15:33:53

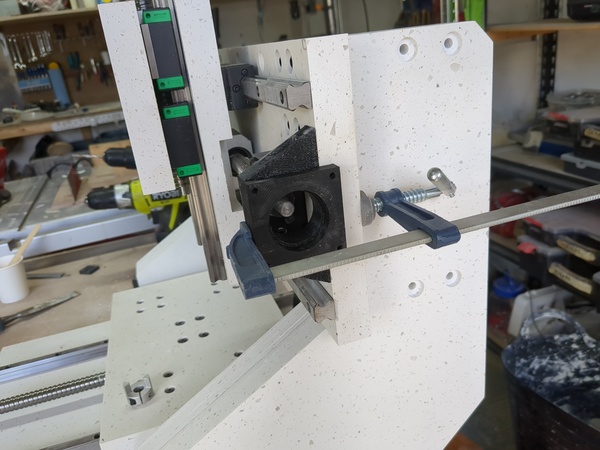

< 2024-06-09 2024-06-11 >I've finished drilling out the motor bracket holes, and am gluing the inserts in place using the brackets as templates:

I cut the inserts in half to work around the cross-threading problem.

Need to take the brackets off at about 1.30pm.

I held up the spindle motor clamp to the Z plate, but it's not obvious where I'll be able to bolt it on. Probably ignore this for now. I can probably get a decent bolting point on each side in between the upper and lower carriage, but not sure about the lower one.

I am thinking that I want to put "stops" on the far ends of the ballscrews to stop it from being possible to drive the nuts off the ends. I think just a cross-drilled hole with a split pin it that retains a suitably-sized washer.

Next up is probably designing the Z motor bracket.

I'm thinking I put some M6 inserts lengthwise into the "X carriage", with some long bolts extending out quite a long way to give some stiffness to the 3d-printed part. And then the 3d-printed part only has to carry torque from the motor-mounting bolts to the bolts extending from the kitchen worktop material.

Let's try this:

And while that's printing... what are my chances of successfully free-handing the cross-drilled holes in the ballscrews?

Not too bad:

Then I turned up 3 washers on the lathe, so there's one like this on each ballscrew:

Might have been better if, when I turned down the ballscrews, I'd made the circlip groove that is on the standard ones, then I could have used a circlip instead of a split pin. I think this will be fine though. It's just meant to prevent all the balls coming out if I accidentally try to drive off the end of the screw.

When I tried to undo the screws to pull the "template" off, one of the inserts stuck to the screw instead of the machine:

I did wonder if this was going to be a problem. I'll re-glue it when I do the Z motor bracket.

The Z motor bracket is slightly too short:

It wants to be about 5mm longer. It's good enough for now for gluing up with though. And in fact it might be easier to make just a square 5mm spacer to join the motor to the bracket. We don't really care about alignment, because the motor needs to be aligned on the shaft rather than on the bracket.

Need to de-template the latest gluing at 7.25pm.

< 2024-06-09 2024-06-11 >