Last modified: 2024-04-19 15:16:03

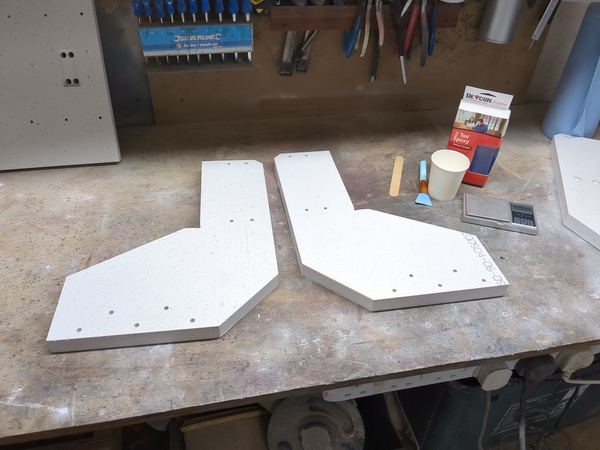

< 2024-04-16 2024-04-20 >My epoxy has arrived, so I think I'm almost ready to glue some frame parts together. First step is cleaning off the dust and then making a tidy workspace.

Mix the epoxy, apply to both surfaces, clamp together, what could go wrong? Then repeat for the other upright & for the base plate, then look at fitting threaded inserts.

Seems to have gone OK-ish. I used about 18g of epoxy (9g hardener + 9g resin). The epoxy was a lot more viscous than I expected very difficult to apply evenly. Also the parts wanted to slip apart as I tightened the clamps, I used a couple of drill bits as alignment pins to mitigate the problem. I'll give the epoxy some time to thicken up and then remove the squeeze-out.

I pulled the drill bits out shortly after tightening the clamps, once of them was already coated in epoxy and difficult to remove.

Second piece glued:

But I've run out of clamps now so I can't do the baseplate now unless I come up with another way of clamping. I think I'll just wait, and do the baseplate tomorrow.

I think the bolt holes may be filling up with epoxy, so I will try to drill those out when the epoxy is half-set, so that I don't have to try to drill it when it's fully hard.

I noticed that after the glue had squeezed out a bit I could tighten the clamps some more, so I am doing that periodically. Once the epoxy stops being runny I'll try to chisel it off.

After about 2 hours I tried to chisel the glue off:

I got most of it off, but it was still a bit soft and sticky, would be better to wait longer.

< 2024-04-16 2024-04-20 >