Last modified: 2024-03-12 20:11:13

< 2024-03-11 2024-03-18 >4 new tyres on both cars today.

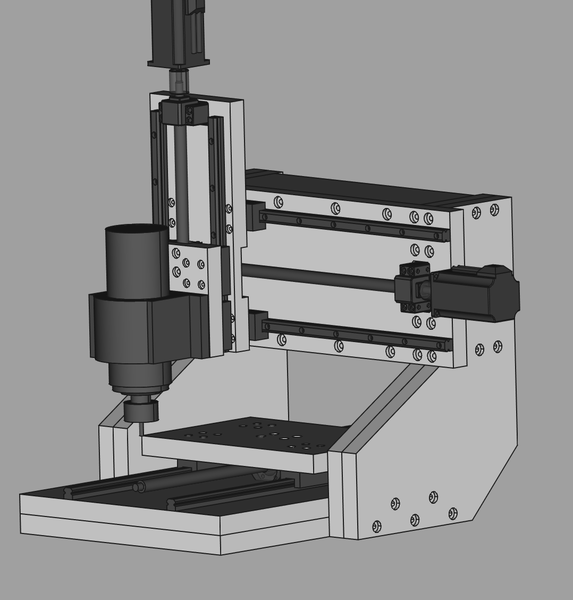

I'm going to put in the hole locations for bolting frame parts together with M6 flanged button-head bolts, then acquire some suitable bolts and threaded sleeves.

Update: the longest readily-available M6 flanged button-head bolts are 60mm, which would only give 10mm of thread engagement when it goes through 2 parts. That would probably be fine but I'd prefer a bit more. Maybe if I sink the heads a bit that'll do? Make the counterbores 15mm diameter and 5mm deep.

All of the frame bolts go through either the uprights (double thickness) or the gantry (single thickness).

I have 18 going through the uprights, want to be 60mm long, with 15mm+ threaded sleeve.

I have 24 going through the gantry, they want to be 35mm long, with 15mm+ threaded sleeve.

I've gone for 25mm threaded sleeves, the outside diameter is "approximately" 10mm. I don't think there's any merit in putting the sleeve holes in the CAD because I'll need to drill them by hand anyways.

Next tasks: