Last modified: 2024-01-07 17:21:56

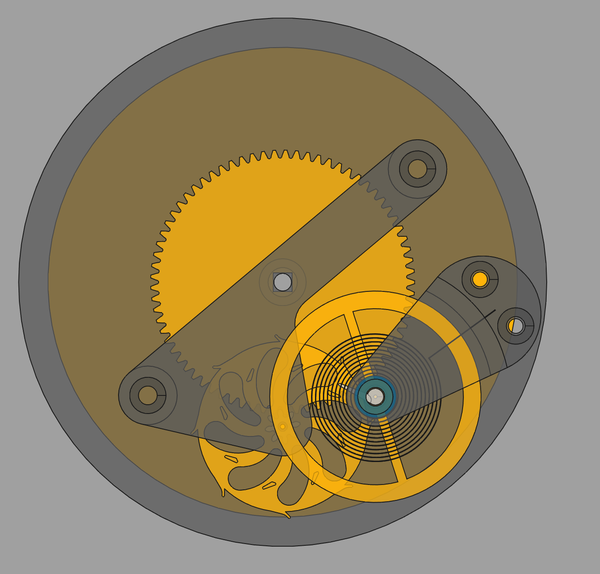

< 2024-01-06 2024-01-09 >Got a balance cock and a bridge in place:

The total height is 11.25mm, but I could lose 1mm off the barrel thickness by making the barrel surfaces 0.5mm instead of 1mm.

It occurred to me that I can press things onto shafts square by using the lathe! Put the shaft in the chuck and a pusher in the tailstock, and use the tailstock to push the part onto the shaft.

Now with bridges, shafts, hairspring:

I think that's mostly it now, just missing the click/clickspring. And the adjustable cone pivot hole for the balance, but I think I'll just turn that in the end of a grub screw, doesn't really need CAD. (Famous last words).

Also missing a hole to pin the hairspring in.

Here's the plan for the balance shaft blank:

The impulse pallet and locking roller will be machined directly onto the shaft.

What are my chances of successfully making this? Especially given that it has to be made out of soft steel, because I don't have any silver steel with a 7mm+ diameter.

To turn the sharp shoulders I'm probably going to need to make my own lathe tools.

Maybe I'll go and have a first pass at making this part, with the expectation of scrapping it, just so I know what I'm up against.

The second operation bruised the surface that the collet gripped on. Maybe I did it up too tight? Maybe it would not be a problem with harder steel? I had to do it up quite tight though because I was using a 3mm collet to grip a 2.4mm diameter.

The shaft is only 7.05mm long, should be 7.30mm. Some of the clearances are as small as 0.25mm, so being off by 0.25mm is probably not good enough.

Cone pivots are easier to make than normal pivots:

I burnished the pivots with the blunt end of a broken carbide tool, which seemed to do a good job of making them shiny, but I couldn't get into sharp corners because of the radius on it, and I had a lot of trouble making sure I was holding it flat against the surface.

The hairspring is loose on the shaft, so this is probably not going to work. Dimensions, compared to intended, are (best to worst):

So that mostly looks pretty good! Maybe it would work, if I could fit the hairspring collet.

Just realised the CAD has the hairspring collet partially sitting on the cone instead of on straight shaft:

I did manage to squash the hairspring collet to make it fit tightly on the shaft, but it is not obvious that it will stay on if it only grips on a tiny portion.

Probably the next thing to do is make the balance wheel, fit the balance wheel to the shaft, and then see if the collet can be convinced to stay in place above the balance wheel.

If so, good, proceed; if not, I probably have to change the CAD to give more space for the hairspring collet, and make a new balance shaft?

< 2024-01-06 2024-01-09 >