Last modified: 2023-12-24 16:42:37

< 2023-12-23 2023-12-26 >Thin barrel, direct-drive hands

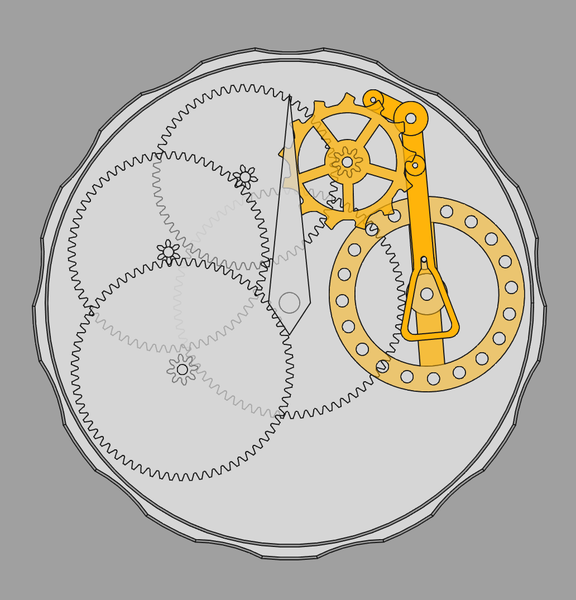

I kind of subconsciously discarded this idea the other day, but it might be easier to make the "thin barrel" with much stiffer wire, and make it turn only once every 12 hours, and have the hand driven directly off the barrel arbor, instead of having the 24x reduction thing on top.

Like this:

That one works out to about 17600 bph, so obviously a workable arrangement. It does have some 6-leaf pinions but if they became 8-leaf it would still be about 10000 bph.

Total gears: 8

Pros:

Cons:

I think this is strictly an improvement over the "hollow barrel". It has all the same pros and much fewer cons.

But I would move the thin barrel so that it sits between the movement and the dial, with both of the movement plates beneath it. The barrel arbor will run all the way down to the lower plate so I think it will be well supported, and that's the only piece that turns. It's OK if turning the barrel itself has a lot of friction because that will only be done by hand when winding.

Next up on making the thin barrel is machining the slot for poking in the wire, and drilling the hole to hook it on.

And testing with a piece of the wire, it looks like the depth is about right, which is good.

I extended the slit down into the surface of the disc slightly to give some more space for the bend radius.

So now I just need a brass disc for the end cap, and then a shaft for the middle.

Here's an end cap:

Made using the superglue arbor, might have been quicker to use the CNC router, not sure.

I've been trying to work out how to keep the 2 parts of the barrel pressed together so that the spring can't overlap itself. Ideas include:

Maybe for now I'll just forget about it and use clamps. So for now I just need a single ~0.4mm cross-drilled hole in a shaft. I'll make the shaft 2mm and drill the barrel holes out to 2mm.

To do the cross-drill I held the rod in the collet chuck in the 4th axis, packed underneath the rod with wood, machined a small flat with the 1mm end mill, and then drilled straight down slowly with a 0.4mm PCB drill. Seems to have worked:

Now to try to assemble it and wind the mainspring.

I tried it out with a random short piece of wire first:

Seems to be sort of working, but not as springy as I had hoped.

I hooked the end into the main piece of the barrel and tried to test it out, and it was sort of working, but I discovered I was tightening it the wrong way and I lost the spiral and then snapped the centre hook off.

I'm going to try with a longer wire now.

Here's my clamping setup:

Hmmm, this isn't really working. I managed this much:

And then the centre hook sheared off. But those aren't acceptable coils anyway, they're packed too tightly even when not tensioned. Also the central coils have ridden over each other despite being clamped in the vice, it looks to have bent the brass out on the side that wasn't clamped by the vice.

Well the obvious cure for the coils being too tight is to wind 3 at a time, like with the hairspring winder idea, so that they space each other automatically.

But I don't know how to stop them from riding over each other. Maybe make the winding tool out of thicker material, and then transfer the wound spring to the thin barrel.

I'll be interested to see what George Daniels says about making mainsprings.

From https://watchmaking.weebly.com/mainspring.html it sounds like he just says to buy them, disappointing.

Well I think the hook shears off because the coils ride over each other which then binds them up. So if I can make a more substantial winder, that won't happen, and then I should be able to wind it further. Also if I make the inner diameter of the winder larger, then the coils will start out packed against the outside of the barrel, and winding the barrel will pull them to the middle, and the spring tension will pull them back out, which I think is what I want.

What's the easiest way to do this? Maybe I could just get a couple of thick pieces with a hole in the middle and use them in the vice to clamp this barrel, then try to wind the spring, and cut off the tight central coils when done? Worth a try.

I'm lazy so I'll try wooden ones first.

Same problem: the central coils rode over each other, bent the brass out, bound up, and then snapped the hook.

Another explanation could be that the brass plates are too tight, which prevents the wire from being pulled in, so the only part that can be move is the central coils, which just get tighter and tighter until they snap the hook. I think that might be the problem, because if I put a wire in the entry slot and squeeze the plates together, I can't move the wire. What a blunder, seems like I could have worked this out sooner. So the barrel needs to be deeper.

I re-measured the piano wire and it is 0.35mm diameter. Why did I think it was 0.25mm?

Putting a sheet of paper between the discs seems to create the required clearance, so I'll try and make a ring of paper and try again.

Maybe??

Well I had to back off on the vice pressure slightly, but I managed to wind the almost-entire 1 metre length into the barrel!

The central coils are still bad, but this is much better:

The centre of the inside of the cap is getting quite badly worn which I think isn't helping.

I cut the central coils off again and wanted to assemble it with the loose end hooked into the hole drilled in the barrel, but it proved almost impossible to assemble. So instead I formed a hook on the loose end and let it catch on the outside of the barrel:

And this is working! I can wind up the pin vice and the spring spins it back. Great success! My first metal mainspring.

Improvements required:

But this is good progress.

https://www.youtube.com/watch?v=8OGLP-gmmj8

Probably next I will shift back to getting the 3d-printed spring-driven mechanism to work.

< 2023-12-23 2023-12-26 >