Last modified: 2023-11-19 21:55:25

< 2023-11-18 2023-11-20 >I'm reprinting the broken parts. The prints don't really look any better, maybe worse. And the elephant's foot is back.

The impulse pin boss sheared off again, this time while I was trying to fit the pin:

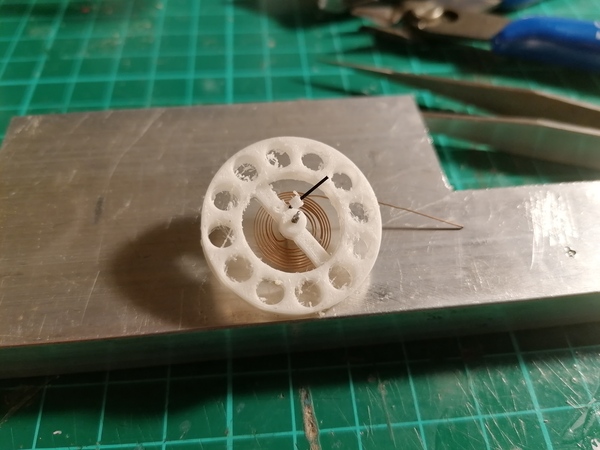

But I got the pin in anyway, and even successfully fitted the hairspring.

I also successfully put the escape wheel on its shaft:

But it is not going to work, the elephant's foot is so bad that the escape wheel can't turn because it hits both pallets at the same time.

So there is some progress today, but not a lot. I probably need to reprint the escape wheel with higher Z offset.

I'm going to start rearranging stuff, in particular I want to get the milling machine into its new position.

I must remember to fix the roof leaks.

OK, I've took all the stuff off the shelf in the back left corner, and dusted off the shelf and moved it next to the pillar drill, dusted off the walls and swept the floor and vacuumed the cobwebs off the ceiling in that corner, and moved the milling machine into its new position.

Control cabinet moved, and everything plugged in and working:

I think the desk is only temporary, because I want it slightly bigger, and I want to be able to sit on a chair and have my legs underneath.

I switched the power wiring over to the other switch, and it has the same problem as the first! So annoying. It switches on but won't switch off. I think the problem is caused by overheating it when soldering the wires on, but I was really careful not to get it too hot this time.

Thinking about the milling machine, I wonder if I would actually get more repeatable results with Z axis backlash compensation turned off, on the basis that once it settles into a cut gravity will do the work of always positioning it in the same place, and it's only the dial indicator that notices the backlash?

The "practical course in horology" book says (page 101) that the escapement should be "banked to the drop", i.e. the limit of motion of the lever should be just beyond what is required to allow the teeth to escape. In my escapement the banking is much further than this, maybe I should remedy that.

Principles it has are:

So let's measure mine (in CAD).

So:

Possible remedies are:

And I don't know how I can decrease the draw angle but also increase the drop lock. Maybe this is just a geometrical problem with using pins for pallets?

I'm not really inclined to make the impulse face steeper, feels like it will cause more friction. But I think I do want it "banked to the drop". Maybe I just need to increase the size of the escape wheel, but leave all the angles the same?