Last modified: 2023-11-12 22:58:52

< 2023-11-11 2023-11-13 >Next step on this is to have another go at making the pinion, but to do that I first want to make a new cutter, out of silver steel, and with a suitable profile for a 7-tooth gear.

So I'll try and order some square-section silver steel. The cutter holder wants 6mm square bar.

Apparently "silver steel" specifically refers to round bar. How do you find similar steel in other shapes?

"College Engineering Supply" have something that they call silver steel.

Rapid Metals only have silver steel in round bar, but have square in O1 and D2.

I've ordered some 6mm square O1 from Rennie Tool on eBay, it is expensive but what can you do?

I had a good idea for the escapement design, to allow amplitudes larger than 180 degrees.

The balance wheel should have its "top" pivot supported by a balance cock, and the impulse pin should stick up higher than the balance cock, and that way the lever can cross over the top of the shaft. Then the amplitude is limited by the width of the balance cock. But 270 degree amplitude should be fine I think. Would be good to make a 3d-printed prototype of this.

Also include:

So if we go for 3x final scale, then we have:

I'm making this in the 3dp-escapement directory.

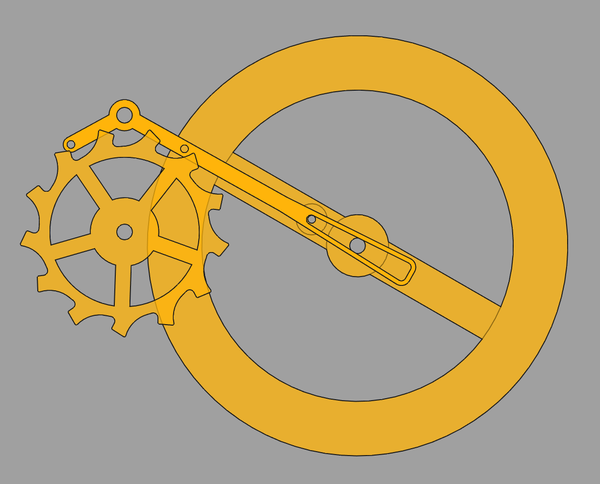

Here's the sort of arrangement I'm looking at:

And you can see that it would be able to work with an amplitude beyond 360 degrees, if not for the impulse pin colliding with the balance cock (not pictured). It would be possible to make the balance wheel sit "above" the balance cock (like all the wheels in the stepper motor clock), and then there would be nothing for the impulse pin to collide with, but it complicates the mounting arrangement.

Since I don't have any 3mm pivot steel I'm going to switch from 3mm with 1.5mm pivots to 2mm with 1mm pivots. And for the barrel I'll let the 2mm pivot slide all the way through, like on the metal prototype, so that it can be removed for winding.

Something like this?

Btw, would I be able to print the watch parts at final scale using a 0.25mm nozzle? Might be interesting to experiment with one. Then I could potentially print the entire mechanism, get it working, and iteratively replace plastic parts with metal ones.

Maybe this would be a good excuse to have 2 printers! One with a 0.6mm nozzle and one with 0.25mm.

Observations I made of Harrison's sea clocks:

I blogged most of it, skipped the parts that are too annoying to explain or I don't have good pictures for: https://incoherency.co.uk/blog/stories/harrison-clocks.html