Last modified: 2023-11-02 08:41:12

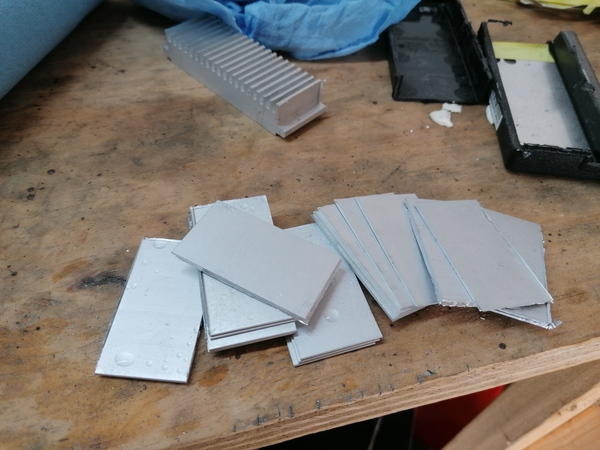

< 2023-10-30 2023-11-02 >I used the bandsaw to cut down an old CPU heatsink:

So now I have 20 aluminium rectangles, about 49.5 * 27 mm, and 1.1 to 1.3 mm thick (slightly tapered). What could I do with these? Use them to make small watch parts? Maybe I could make my "micro CNC mill" and make it hold blanks of about this size?

I used the milling machine to tidy up the cut edges, and trim some more fins off to provide space for mounting screws. Great success:

Ruari says it will be an expensive clock to run if it needs such a big heatsink, but I'm not so sure. The transformer says the output is "12v ~ 2W", and the transformer isn't getting appreciably warm, which makes me think it's drawing less than the 2W that the transformer is rated for. I think the motor just gets hot because basically all of the power it draws is turned into heat, and it's not very efficient at shedding heat.

But I went to measure how much current it is drawing, only to find that my multimeter can't measure AC current, so I've ordered a clamp meter. I'm also going to leave the motor running for a bit and see how hot it gets. Started at 14:20. Without the heatsink it got too hot to touch in well under an hour.

Next to the material I cut it out from:

There's hardly any of the original surfaces left, but probably still slightly less work than machining fins out of a solid block.

14:43: it's warm but not excessively so, maybe the temperature of a hot bath. Maybe about 40 deg. C?

The heatsink feels hotter than the front of the motor does (the back of the motor is the hot bit), so I think the heat transfer into the heatsink is adequate.

15:38: broadly the same as before. I reckon about 40 deg. C. So I reckon it has stabilised, and the heatsink works. Great success.

< 2023-10-30 2023-11-02 >