Last modified: 2023-10-30 19:55:25

< 2023-10-29 2023-11-01 >The printer has been having trouble with the first layer height, and now the nozzle is jammed and I can't unload the filament.

I've cleaned out the extruder, which had a lot of gunk in the filament drive gear thing, including some bits of solder from when I tried to 3d print solder. So that should be better, but I still can't pull the filament out of the hot end.

I've rebuilt the hot end and cleared all the gunk out, and fitted a brand new 0.6mm nozzle.

Still won't feed filament through the nozzle :(. It acts like it's blocked. I didn't check that the nozzle does actually have a hole in the middle, but you'd assume it does as it's brand new.

With the nozzle removed it pushes filament out of the hot end with no issue.

I removed and reinstalled the nozzle, seems fine now. Don't know what was wrong.

I'm going to try and address all of the tight spots. I've pulled all of the gears off (which is pretty easy, except for the first wheel, which is very tight in its bearings).

I'm installing pairs of gears one at a time and spinning them together to check how free they are, and using a Stanley knife to trim the teeth that are tight. Is there a better way?

I also found that the reason the magnet friction joint had tight spots was due to the hole in the large gear binding on the shaft. I drilled that out to 6mm and it is much improved.

I took the first wheel shaft to the lathe and turned it down very slightly using a file and green sanding sponge, and now it fits nicely.

I've fitted the dial feet.

So next up, let's do some CAD for a dial.

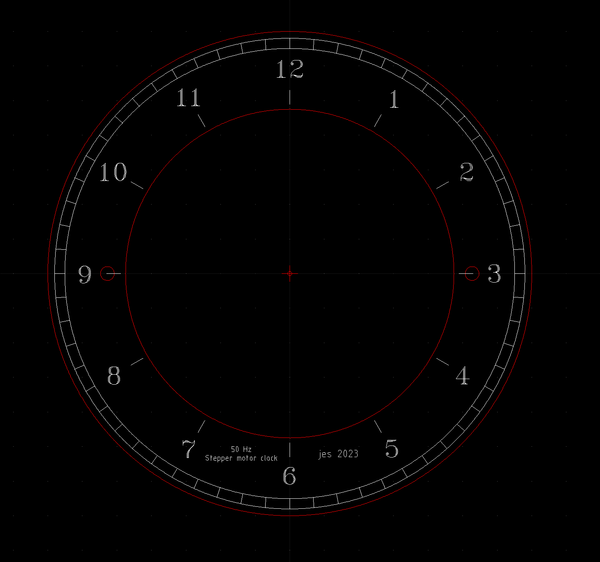

Done in LibreCAD even though it has no CAM and I said I wouldn't use it again. I imported it into Inkscape with scale factor 0.264583, used Gcodetools to make a path, and then loaded the path in FreeCAD to check that it is scaled correctly, it looks OK:

So now a quick FreeCAD Path job to cut out the circle, and then get it made. Out of 5mm plywood I think.

Looking good:

I sprayed it white and then engraved with the 0.5mm tapered ball end mill. The smallest text is too small really, it could just as easily say "Stopper meter clock". But this is fine. I will spray lacquer the dial at the same time as the frame. Annoyingly the dial has to be removed to install/remove the gears.

I left it running for a little while, and found it stopped. The motor was still going round, but the train was slipping at the magnetic joint. I've left it parked in the tight spot. (Update: think I've fixed it).

Next up: