Last modified: 2023-10-25 20:57:54

< 2023-10-24 2023-10-26 >I've uploaded it to printables: https://www.printables.com/model/625901-self-aligning-boggle

Now what do I want to put in the demo video?

https://www.youtube.com/watch?v=ykt3Z8U7-CI

I submitted it to "Hasbro Spark", which seems to be designed for kids to submit crayon drawings of their toy ideas.

And I wrote a blog post: https://incoherency.co.uk/blog/stories/self-aligning-boggle.html

So, great success. I'm finished with the Boggle project.

I realised I don't want retaining collars on the fronts of the shafts. I want the gears to just fit tightly. So I've got rid of all the front collars, and on the second wheel shaft, where one of the gears needs to be able to slip, I will make the front one tight and the back one loose, so that the front one stops them from both falling off the shaft.

For a heatsink I will just bolt a bit of aluminium to the back of the case in such a way that it presses on the motor.

I'm not going to make the bearing blocks longer, I think this will be fine.

So the next bit is making the hands attach to their shafts. To make the hands I need to know how big the dial will be, which I'm struggling with a bit. I don't want the clock to have to be too much wider than the diameter of the largest gear, but I also don't want the dial to obscure any of the works.

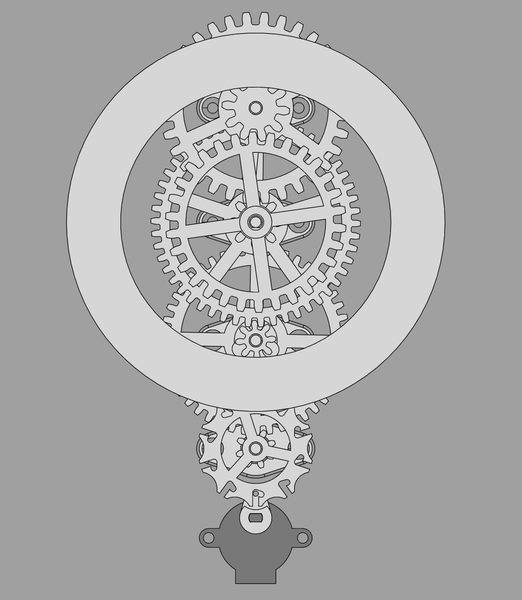

Maybe something like this?

I think that doesn't obscure any of the interesting parts, all of the interacting parts are still visible. That's 140mm across. This clock is going to be smaller than I thought.

One issue is that if the dial is hollow in the centre like that then there is nothing to hold the 6701 bearing, so the hour wheel might end up wobbly.

< 2023-10-24 2023-10-26 >