Last modified: 2023-09-17 15:44:30

< 2023-09-15 2023-09-17 >Contrary to the "plan" I wrote yesterday, I decided to try and make some staking tools today.

I wanted to make a big flat piece of metal with various-sized holes in it that I can use to hammer shafts through gears etc.

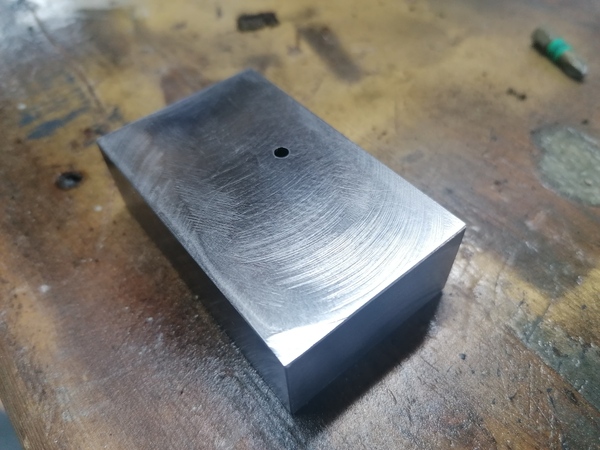

I went to great pains to square up the piece of D2 tool steel that I had, fly-cutting every surface, draw filing, chamfering the edges, and even polishing the two large flat faces (a bit).

Then I put the 1.1mm PCB drill in the pillar drill, and... I couldn't drill a hole. Eventually I snapped the drill off. This steel is too hard.

Then I tried a 2mm drill, but because it doesn't have the large shank like the PCB drills do, I couldn't hold it in the chuck.

Then I tried a 3mm drill, and I did manage to drill a hole but it was tough going. It felt like if I paused at all, the material work-hardened and was then very difficult to push through, until I broke through and it drilled quite well for a while.

So I think D2 tool steel is not a good material for me to use, it is too difficult to work with.

I do have a block of mild steel that I could use instead, but if I try this again I won't bother going to so much trouble to make the material nice before I've managed to drill any holes...

This guy has a decent homemade Tourbillon project on YouTube: https://www.youtube.com/watch?v=PlT8Gdg_m4c He has a big and professional Haas machine, but some of the techniques are applicable anyway.

I had another go in a piece of aluminium:

I did try to drill a 0.6mm hole in the middle (where the "X" is) using the pillar drill, but snapped off the PCB drill. I then tried a 0.7mm PCB drill, while wearing the 5x loupe, and managed to drill it some of the way! I stopped pretty early though, didn't want to push my luck. Then I wondered if I could make the hole deeper by drilling by hand using the pin vice, and I snapped off the 0.7mm drill, leaving part of it behind in the hole.

Probably I should be using either the router or the milling machine when drilling these tiny holes. Or don't make them so deep. I only need the top 1 mm or so to be at the correct diameter, the rest of the depth can be counter-drilled from the other side to whatever arbitrary diameter is easy.

I saw this video on YouTube: https://www.youtube.com/watch?v=5CeCxkFVCdM

It details a homemade EDM machine. It's simpler than it sounds.

The clip features a segment running at 72V 0.8A at 2kHz. Is that really all there is to it? Make a 72V 0.8A 2kHz square wave and off you go?

You can buy a 72V power supply capable of providing 8.3A for £48 on eBay, maybe can be done cheaper.

He also uses a PCB resistor (like a 3d printer heated bed) for current-limiting, presumably to limit the impact of short circuits. But his first revision used 7 off-the-shelf power resistors, which are less than £5 each.

He also implies that there is some sort of short detection that (presumably) switches off the power supply if it detects a short. You can do this with a voltage divider and an analogue input.

The part is suspended in a bath with distilled water pumped across the surface of the stock. An aquarium pump would do. £15.

I think the part is grounded and the electrode is connected to the 2kHz supply.

So I'd need to spend less than £100 to acquire a power supply, power MOSFET, resistors, and aquarium pump, and then make a bath of some kind which can hold the stock submerged and grounded near the inlet/outlet to the pump.

Then make an attachment to hold the electrode on the Z axis.

Then make the over-current detection trigger the emergency stop in Grbl so that Grbl stops moving when something shorts out.

Is that all? Would that work? Ponder this some more! Maybe this is a better way to make small parts than tiny end mills is.

More info about making EDM machines: http://www.homebuiltedmmachines.com/

Don't do this. This is a pointless side project that won't help me make a watch any faster!

Let's carry over yesterday's todo list...

I'm wondering if it would be a good idea to buy ready-made pivot steel in (say) 0.5mm diameter and 1mm diameter. The 1mm pieces would be bored to 0.5mm so that they can be fitted over the actual pivots, and then we'd have a nice square shoulder and a good quality pivot without having to turn tiny features, and the gears and pinions can be pressed onto the 1mm piece.

Making the long 0.5mm bore may be more challenging than learning how to make good pivots myself.

< 2023-09-15 2023-09-17 >