Last modified: 2023-09-14 16:01:25

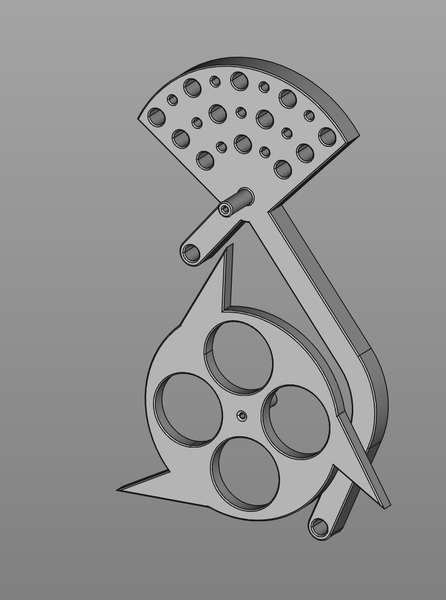

< 2023-09-07 2023-09-10 >First thing, I modelled the weird 3-arm escapement:

And waiting for it to print. That's a fun distraction but not necessarily relevant to the watch project.

It works but not very well, and is very sensitive to the positioning of the weights: https://www.youtube.com/watch?v=4VKekXIMRhg

I think it would work a lot better if the "balance wheel" were actually balanced.

I think next things to look at on the watch are:

Here's the process I want to use:

Wish me luck!

Update: the 4th axis is out of concentric by about 0.25mm now. So that's an improvement on 0.4mm but not as much as I had hoped. I don't know if it's going to be 0.25mm every time or if it depends how it gets bolted on. Will monitor it. It's possible that there is an optimal orientation and I just need to centre-punch next to one of the bolt slots.

So I better work on the Perl script to help me cut concentric gears on an eccentric axis...

The Perl script is in ~/concentric-gear-cutting. I plan to maybe put it on jesref or something.

It went really well! I forgot to bore the hole until after I'd cut the teeth, so it had to be transferred back to the lathe for that, but that's fine. I can just try not to forget in future. It looks pretty central anyway.

It's a bit bigger than the last one (33 teeth instead of 26) so harder to fit in shot for the microscope.

But the teeth are much more uniform. I think the Perl script is a good success. Just crossing-out left and then I think that's gears solved. I'll probably do crossing-out on the CNC router. First mill a circular pocket that's a good fit for the gear. Superglue it in. Leave the coordinate system alone. Cut the crossing-out with a tiny end mill.

Oh, also probably wants a better cutter (made of silver steel?) and maybe a better finish. But I think those are small problems, pinions are next.