This post is a transcription, plus some commentary, of the Board of Longitude's 1767 document "The Principles of Mr. Harrison's Time-keeper", from scans on the University of Cambridge Digital Library.

I was trying to learn more about the escapement in H4, and I came across a great article on "watchesbysjx": In-Depth: The Microscopic Magic of H4, Harrison's First Sea Watch, from which the scans were linked.

I have turned the English pages of the scan into a PDF for more convenient reading, you can get it here: The Principles of Mr. Harrison's Time-keeper. Sadly the first couple of pages from the Preface, and the last couple of figures, are missing from the scan and therefore from my PDF.

(Btw, if you're into this sort of stuff, I scanned in my copy of Rupert Gould's John Harrison and his Timekeepers recently - Gould rediscovered and restored Harrison's clocks in the early 20th century, and he also wrote "The Marine Chronometer: Its History and Development", which is worth a read but perhaps not at the £615 that Amazon are currently charging).

The original from 1767 is typeset in the style of the time, including use of the "long s", and "vv" instead of "w", but it is quite readable once you get used to it. In this post I have updated spelling to match modern usage, and turned Roman numerals into normal digits, but left sentence structure and capitalisation the same.

The document is split into 2 parts. First we have "Notes taken at the Discovery of Mr. Harrison's Time-keeper" by Nevil Maskelyne, Astronomer Royal. Then we have "Principles of Mr. Harrison's Time-keeper" written by John Harrison himself, which ends with notes on the figures followed by plates containing the figures, which I've rearranged in this post to make it easier to read.

The text in blockquotes is my transcription of the original, the rest is my commentary.

Notes taken at the Discovery of Mr. Harrison's Time-keeper

This part is written by Nevil Maskelyne, who was opposed to the use of a clock for determining longitude, and who preferred the lunar distance method, although his notes here appear perfectly impartial.

The "Discovery" was the event at which Harrison took the watch apart and explained it. It began on Wednesday 14 August 1765 and took place at Harrison's house in Red Lion Square, observed by Maskelyne, plus three watchmakers (Larcum Kendall, Thomas Mudge, and William Matthews), two reverends (William Ludlam and John Michell), and astronomer and instrument maker John Bird (source: "Harrison" by Jonathan Betts, highly recommended).

The balance naturally vibrates largest arcs, when in a horizontal position; next greatest, when the hours 12 and 6 are uppermost, and the watch is in a vertical position; least, when the hours 3 and 9 are uppermost.

Large arcs are naturally performed in less time than small ones. This Mr. Harrison inferred, because the watch, before any correction was applied, went slower in a vertical position than in the horizontal one, and the vibrations are visibly larger in the latter case.

The watch is adjusted to vibrate great and small arcs in equal times, in the following manner:

To go the same when placed vertically with the hours 3, 6, 9, 12 upwards successively, by making the weight of the balance different in different parts.—To go the same when placed horizontal as when vertical, by the joint effect of the back of the pallets and the cycloid-pin.

I don't see how making the weight of the balance different in different parts can affect how the watch runs in different positions. If you keep the centre of mass in the centre (which you should, else it's not balanced) and the moment of inertia the same (which you should, else it will run at a different rate) then I don't see how changing the distribution of weight around its perimeter has any effect. Is it Harrison, Maskelyne, or me that is wrong here?

The curve of the back of the pallets is an arc of a circle, whose centre lies in the line joining the edges of the pallets and the centre of the spindle, the distance of the two centres being two fifths, and the radius of the curve of the pallets three fifths of the radius of the circle described by the edge of the pallets.

The description here suggests that the backs of the pallets are circular, but elsewhere they are described as cycloidal.

There is a good description of the escapement on the watchesbysjx article.

The action of the cycloid-pin, when it touches the balance-spring, tends to quicken its vibrations; and the spring, leaving the pin for a longer time in the large vibrations than in the small ones, is less accelerated by it in the former than in the latter case; and, consequently, the action of the pin tends to reduce the time of the different vibrations nearer to equality. The cycloid-pin was not applied to the watch until after it came back from the voyage to Jamaica.

If the balance-spring is too strong, it must be made weaker by rubbing it away a little; but, if it be too weak, it must be changed for a stronger.

The balance-spring is fastened at the outer end to a stud, which takes off the plate with a screw, and is put on again with the same screw, and steady-pins, exactly in the same position as before, without undoing the fastening of the spring to the stud at the end.

There is no adjustment for mean time, as in common watches; there was once, but it did not answer.

"Mean time" here is as distinct from solar time, which people of the 1700s would probably have been more familiar with. "Did not answer" presumably means that it didn't help with keeping time.

"Common watches" provided an adjustment to speed up or slow down the watch so that it would indicate the passage of about 1 day per day, but Harrison's watch had no such provision. This speaks to the purpose of the watch. To allow a human operator to determine longitude at sea, the operator had to be able to determine the time accurately. It was more important that the watch run at a known rate than that the rate be 1 day per day. Once the rate is known it is easy enough for the operator on board a ship to apply the rate to determine the true mean time. (If the watch loses 10 seconds per day, and 10 days have passed, then it's lost 100 seconds).

If adding a rate adjustment would upset the other adjustments, then in the context of a marine chronometer, it is preferable to forgo the rate adjustment and keep the known rate than to have the watch run at approximately mean time, but with larger errors.

As soon as the watch is put together, Mr. Harrison says, it will show its rate of going in three hours accurately the same which it will keep afterwards; so that he can soon determine it by comparison with his pendulum clock.

The balance-spring, when at rest, touches the cycloid-pin; and does not begin to leave it, until the balance has vibrated an arc of forty five degrees beyong the point of rest, while the spring is in the state of coiling itself up.

The thermometer curb is composed of two thin plates of brass and steel riveted together in several places, which, by the greater expansion of brass than steel by heat, and contraction by cold, becomes convex on the brass side in hot weather, and convex on the steel side in cold weather; whence, one end being fixed, the other end obtains a motion corresponding with the changes of heat and cold, and the two pins at this end, between whcih the balance-spring passes, and which it touches alternately as the spring bends and unbends itself, will shorten or lengthen the spring, as the changes of heat and cold would otherwise require to be done by the hand, in the manner used for regulating a common watch.

Mr. Harrison requires cold weather for adjusting the thermometer curb, and he places the watch near a fire, with a common thermometer by it, to try if it keeps the same time as in the cold air. If not, he alters or adjusts the thermometer curb until it goes the same in these two different degrees of temperature of the air.

The thermometer curb takes heat sooner than the balance-spring, and he thence concludes that brass takes heat sooner than steel, and that the brass rods of a gridiron pendulum should be made thicker than the steel ones.

Agreed. Brass has both a lower specific heat capacity than steel and higher thermal conductivity. Good idea about making the brass rods thicker than the steel ones in a gridiron pendulum.

Whilst the heat is increasing, the watch will sometimes go one tenth of a second slower in three hours, than when the heat is come to a stand.

It's remarkable that Harrison was able to measure this. What he's saying is that although the temperature compensation works correctly in a steady state, the difference between the rate at which brass and steel "take heat" means the temperature compensation is "wrong" while the temperature is changing.

The effect of the thermometer is increased by rubbing the sides thinner, and is lessened by thickening the edge by burnishing it.

I don't see how burnishing the edge makes it thicker. Does he mean by squashing it in the perpendicular axis to thicken it in the axis that matters?

Mr. Harrison adjusts the thermometer curb first, that is to say, before he adjusts the watch to go the same in different positions.

The watch may be put with figure 12 turned each day alternately different ways, for fear one part of the box in which it is kept may be hotter than the other.

This is advice for how the watch might be used on a ship: turn it around every day so that the temperature difference across the watch is averaged out.

The force or momentum of the balance, Mr. Harrison says, is as the square of its diameter, also as the square of the velocity, its weight being given.

Agreed. For a given angular velocity, the angular momentum of the balance is proportional to its moment of inertia, which for a "cylindrical shell" is I = mR2. And for a given moment of inertia and angular velocity, the kinetic energy is proportional to the square of the moment of inertia, K = 1/2 I ω2.

The momentum of the balance acquired by increasing the velocity is better than that acquired by increasing the weight; as friction is not thereby increased, perhaps, if any thing, diminished, and the resistance of the air only is increased, the effect of which is tolerably uniform, and of great service.

The idea of air resistance being a great service is peculiar to Harrison. Most watch and clockmakers, before and since, have seen air resistance as a source of error to be eliminated. Harrison liked air resistance for two reasons.

Firstly, you want a good amount of inefficiency in the balance, so that when the motion of the balance is disturbed, it very quickly gets back into equilibrium. If the balance hardly loses any energy during a cycle, then the escapement must be designed to hardly provide any energy during a cycle, so disturbances stay around for longer.

And secondly, if the clock can be provoked to run faster in longer arcs, then you get some temperature compensation "for free", because when the temperature increases, the air density decreases, which means there is less air resistance, so the balance swings further which makes it run faster; but also the increase in temperature makes everything expand, which increases the moment of inertia of the balance, which makes it run slower.

This second effect relies on the clock having sufficient influence from air resistance, which I'm not sure applied in the case of H4, but was definitely used by Harrison on pendulum clocks (source: "Harrison Decoded" by Rory McEvoy and Jonathan Betts).

The diameter of the balance is 2.2 inches, of the plate 3.8 inches.

The balance should be a little larger, or 2.25 inches, according to a memorandum taken by Mr. Bird.

The watch makes just five beats in a second of time.

If the balance vibrated faster, the resistance of the air would be too great.

A pocket watch of this kind would do better with six beats in a second.

?? Make your mind up.

A certain size is best for the pallets, or rather a certain proportion between the diameter of the circle described by the edge of the pallets and the diameter of the balance-wheel. This was first suggested to Mr. Harrison from bell-ringing; for he could bring the bell better into a motion, by touching it from time to time somewhere near the centre than near the circumference; because in the first case his hand moved quick enough to follow the bell.

I think this is quite clumsily worded. What he's saying is that the motion of the pallets needs to be small enough that the escape wheel is able to accelerate fast enough to interact with them. So the ratio of the diameter of the pallets to the balance wheel is not really what you care about.

The grand principle of the watch is that of giving the greatest motion possible to the balance with a given force. This is done by the scaping and proper quantity of the arc described.

This note was communicated by Mr. Mudge, as also the following; That the balance, by the force from the wheels, without its spring, tends to vibrate once in two seconds.

There are four springs in the watch; first, a main spring; secondly, a spring in the inside of the fusee, to keep it going while it is winding up; thirdly, a spring, which is wound up eight times every minute; fourthly, the balance-spring. The three first were made by Maberley.

The fusee has six turns and a quarter.

The fly serves to moderate the velocity with which the spring nearest the balance would otherwise be wound up.

This is talking about the remontoire, which we'll see in more detail in Harrison's part. The "fly" is basically an air brake. It has vanes that stick into the air and meet with air resistance as it spins around.

The pivot-holes are all made in rubies, with diamonds at the ends.

The pallets are diamonds.

It is apparently still unknown how Harrison managed to shape the tiny and precise radii on the diamonds (source: "Harrison" by Jonathan Betts) (but, as a point of philosophy: that fact shouldn't motivate any particular curiosity on your part - if you don't know either way, what difference does it make whether anyone else knows? you should be no less curious about all the things that other people do know!).

One end of the watch in the late voyage to Barbados was set higher, because it was not equally adjusted in all positions. Also it was altered and brought back to the same position, with respect to the horizon, as the ship lay down on the one or the other tack, by the help of a moveable box, with a divided arch.

I'm not quite sure what he means by a moveable box with a divided arch. What is a divided arch? Elsewhere the word "arch" is used to mean "arc" and I have transcribed it as "arc", but in this case since I'm not sure of the meaning I left it alone. In any case, what's a divided arc? How does it help to bring the watch to the same position with respect to the horizon?

I'm thinking it must be either a gimballed mount, or something that lets the human operator compare the angle of the box to the horizon (by comparing the horizon to the divisons on an arch?) and adjusting it manually.

Mr. William Harrison reckons the greatest roll of a ship fifteen degrees, and the greatest lie-down, when going upon one tack, twelve degrees.

Hold the watch a little back, when in a vertical position, that the face may be a little up.

If the balance-spring be not exactly parallel to the plates, there will be a small difference in the going of the watch, when the face is up or down.

I guess this is because the balance spring would then be pulling the balance against one or other of the bearing caps, which would either be mitigated or exacerbated depending on which way up it sits?

Care is to be used in moving the watch, or in turning it about, in order to wind it up, not to give it any quick circular motion in the plane of the balance, as it might possibly stop it. A pocket-watch, which Mr. Harrison has made of this kind, once stopped this way. Turn the watch over upon some diameter of the dial-plate, as an axis, in order to bring it into a convenient position, when you want to wind it up.

It's interesting that this was already a problem in 1767. This is a problem that was only to get worse as the chronometer was developed further.

It is quite difficult to disturb a watch so as to take almost exactly all of the energy out of the balance, at a point where it is near the centre, and thereby bring it to a complete stop. But the later chronometer escapement was vulnerable to tripping, which is where a disturbance instead adds energy to the balance, sufficient to let it do another "lap" and gain a 2nd impulse from the escapement. Thereafter, due to the extra energy that keeps getting maintained by the 2nd impulse, the balance will do a second lap on every cycle and the clock will run twice as fast as it should. (source: "The Marine Chronometer: Its History and Developments" by Rupert Gould).

Oil must be applied to the pallets and pivot-holes of the watch, but very sparingly.

This is anathema to Harrison, but apparently his anti-friction wheels couldn't be satisfactorily miniaturised for the watch (source: "Harrison" by Jonathan Betts).

At the time of the discovery, in August 1765, Mr. Harrison said, that the watch then went a little slower than it had done, owing to its wanting to be cleaned, viz. two or three seconds per day.

The "discovery" here is again the event where Harrison explained the watch.

The watch should have a cap, and no outer case, the wooden box, in which it should be kept, serving that purpose better.

I'm not sure what this means. The watch is pair-cased, is Maskelyne saying that the outer case should not be used?

Principles of Mr. Harrison's Time-keeper

Now we get to Harrison's part. In "Harrison", Betts writes that this is "arguably the most seminal of all publications in the history of the chronometer".

In this Time-keeper there is the greatest Care taken to avoid Friction as much as can be, by the Wheels moving on small Pivots, and in Ruby-holes, and high Numbers in the Wheels and Pinions.

The Part which measures Time goes but the eighth Part of a Minute without winding up; so that Part is very simple, as this Winding-up is performed at the Wheel next to the Balance-wheel; by which Means, there is always an equal Force acting at that Wheel, and all the rest of the Work has no more to do in measuring Time, than the Person that winds them up once a Day.

This is talking about the remontoire, the winding of which is slowed down by the fly that Maskelyne mentioned.

The big idea here is that you can almost totally forget about variations of torque due to the mainspring winding down, or changes oil thickness etc. in most of the gear train of the watch. You only really care about the parts from the remontoire to the balance, it is like a self-contained clock that only runs for 8 seconds between automatic windings.

There is a Spring in the Inside of the Fusee, which I will call a secondary Main-spring. This Spring is always kept stretched to a certain Tension by the Main-spring, and during the Time of winding up the Time-keeper, at which Time the Main-spring is not suffered to act, this secondary Spring supplies its Place.

Without this "secondary mainspring", the fusee does not transmit any power to the gear train while the clock is being wound, because the act of winding it takes the spring tension away from the train.

In common Watches in general the Wheels have about One-thrid the Dominion over the Balance that the Balance-spring has; that is, if the Power the Balance-spring has over the Balance be called Three, that from the Wheels is One; but in this my Time-keeper, the Wheels have only about One-eightieth Part of the Power over the Balance that the Balance-spring has; and it must be allowed, the less the Wheels have to do with the Balance, the better. The Wheels in a common Watch having this great Dominion over the Balance, they can, when the Watch is wound up, and the Balance at rest, set the Watch a-going; but when my Time-keeper's Balance is at rest, and the Spring is wound up, the Force of the Wheels can no more set it a-going, than the Force of the Wheels of a common Regulator can, when the Weight is wound up, set the Pendulum a-vibrating; nor will the Force from the Wheels move the Balance, when at rest, to a greater Angle in Proportion to the Vibration that it is to fetch, than the Force of the Wheels of a common Regulator can move the Pendulum from the Perpendicular, when it is at rest.

My Time-keeper's Balance is more than three times the Weight of a large sized common Watch-balance, and three times its Diameter; and a common Watch-balance goes through about six Inches of Space in a Second, but mine goes through about twenty-four Inches in that Time: So that had my Time-keeper only these Advantages over a common Watch, a good Performance might be expected from it. But my Time-keeper is not affected by the different Degrees of Heat and Cold, nor Agitation of the Ship; and the Force from the Wheels is applied to the Balance in such a Manner, together with the Shape of the Balance-spring, and (if I may be allowed the Term) an artificial Cycloid, which acts at this Spring; so that from these Contrivances, let the Balance vibrate more or less, all its Vibrations are performed in the same Time; and therefore, if it go at all, it must go true. So that it is plain from this, that such a Time-keeper goes entirely from Principle, and not from Chance.

The following is a Description of theDrawings from which my fourth Time-keeper was made, and the Drawings are also hereunto annexed.

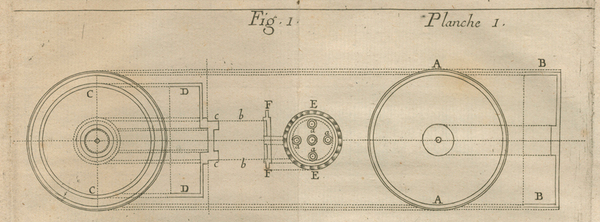

Fig. 1

AA is the Chain-barrel, and BB is a Section of it.

CC is the Spring-barrel, and DD is a Section of it.

EE is a Ratchet at the Spring-barrel, and FF is a Section of it. This Ratchet is screwed to the Spring-barrel by four small Screws at aaaa. There is a hole in the Pillar-plate of the Diameter from the dotted Lines bb, and that Part of the Spring-barrel cc is to mvoe in this Hole without any Shake, in order to set the Spring up. The Ratchet is also shown in Figure 13th, by the Circle bb, and it has thirty Teeth, and c is the Click that holds it.

Diameter of the spring Arbor: about 1.64 of 1/4 Inch.

Diameter of the Hole in the Centre of the Chain Barrel about: 0.38

Diameter of the upper pivot: 0.23

Diameter of the lower: 0.215

Diameter of the spring Barrel within: 1.4 Inch.

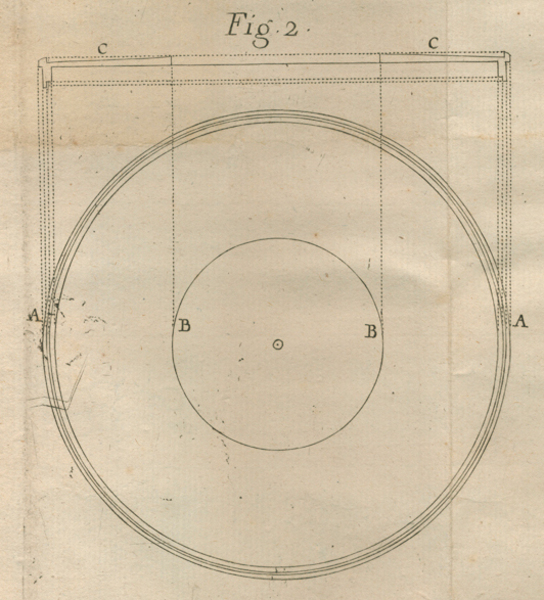

Fig. 2

AA is the Brass Edge, BB the Hole in the Middle of it, and CC is a Section of it. This Brass Edge is supported by six Pillars, and their Places are represented in Figures 13 and 14, by six Circles aaaaaa.

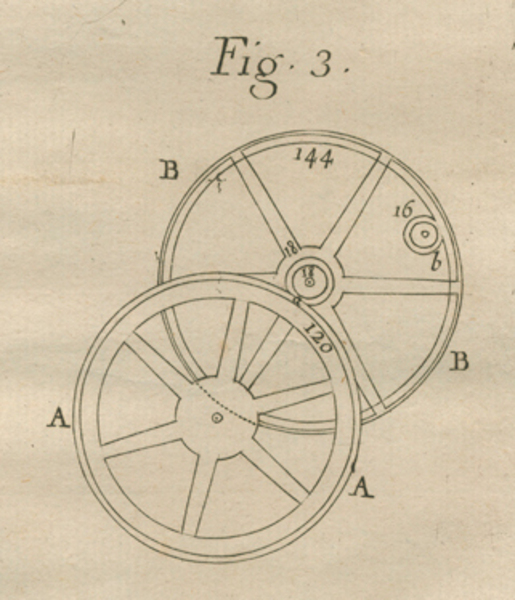

Fig. 3

AA represents the second Wheel acting in a Pinion at a. BB represents the third Wheel, which is concave, and acts in a Pinion at b. The second Wheel is described in Figure 14 by the Circle dd, and acts in a Pinion of 18 at e. The third Wheel is represented in Figure 14 by the Circle ff, acting in a Pinion of 16 at g.

Note, The third Wheel is larger than is represnted in Figure 14, and has 144 Teeth, and the second Wheel has 120 Teeth.

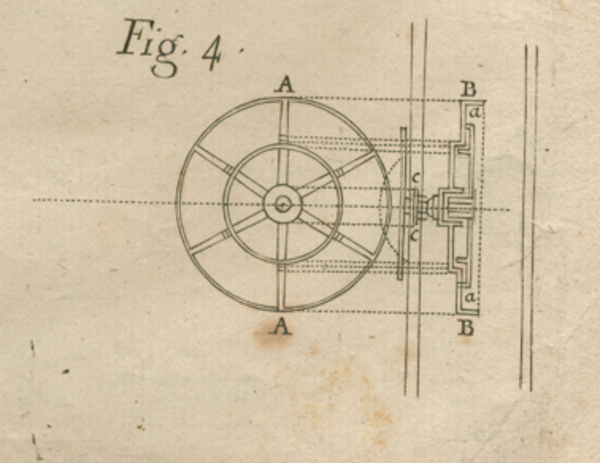

Fig. 4

AA represents the contrate Wheel, BB a Section of it, with a Section of the Spring-barrel aa. At cc is a Piece with eight Pins in it, that discharges the running Wheels every eighth Part of a Minute. This Wheel is also represented in Figure 14 by the Circle hh; it has 120 Teeth, and acts in a Pinion of 12 at i.

Thickness of the Rim about 0.048 of 1/4 inch.

The discharger and wheel for the seconds, must be a little nearer the dial plate than according to this drawing so that the tops of the pins of the discharger may be even with the plane of the pillar plate.

The crosses of the wheel are also drawn too broad at the outer end.

Diameter of the hole in the centre of the wheel about 0.23 of 1/4 inch.

Diameter of that part of the spindle which goes through the fourth wheel arbor (thicker end) about 0.108 of 1/4 inch.

Diameter of each pivot 0.045.

Length of the spring 10 inches, its weight 3.5 grains.

The second paragraph here reads like it was written by somebody else. The capitalisation is unlike Harrison's. Perhaps he dictated that part at a separate time?

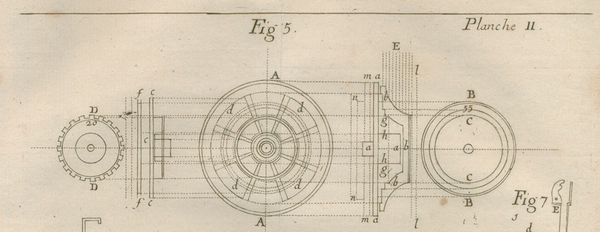

Fig. 5

AA is the first Wheel, and aaaa is a Section of it. bbb is a Section of the Fusee. BB is the outer Diameter of a Ratchet which is fixed to the Inside of the Fusee, and the inner Circle CC is its inner Diameter, and it has 55 Teeth in it. dddd is what I call the perpetual Ratcher, of which cccc is a Section; there is a Ratchet with 75 Teeth in it on that Part marked ff, this is also shown in Figure 13 by the Circle ee, and this perpetual Ratchet is to carry the Barrel DD, which Barrel contains the secondary Main-spring, and will be in the Inside of the Fusee at gg, and at that Part of the first Wheel hh the inner End of this Spring is to act, as that Part hh will be its Arbor. The dotted Lines E represent the Grooves in the Fusee. The dotted Lines ll represent the upper Plate. The dotted Lines mm represent the Pillar Plate. The dotted Lines nn represent the Cock, which carries the lower End of the Arbor of the first Wheel. This Cock is also represented in Figure 13 at dddd. The Ratchet ee in Figure 13 has two Clicks, whose Centres are at ff, and gg are the Springs which act at these Clicks. In Figure 14 bb represents the first Wheel with 96 Teeth, acting in a Pinion of 21 at c.

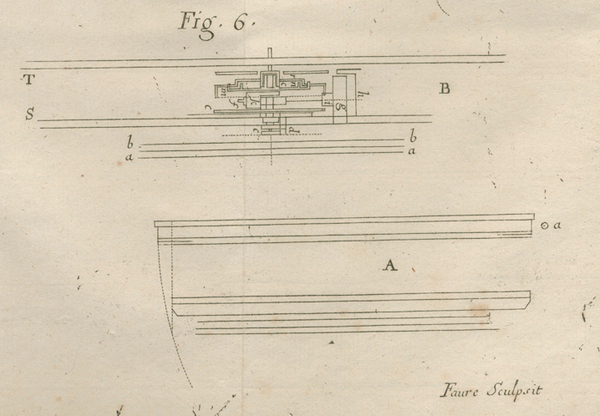

Fig. 6

A is a Section of the Frame, with the Balance-cock, the Slide, and the Brass Edge; and a is the Centre of the Joint-pin. B is a Section, where aa represents the Balance-cock, bb the third Wheel-cock.

c the Cock at the End of the contrate Wheel.

d the Cock at the End of the fourth Wheel.

e the fourth Wheel.

f the Follower.

g the Balance-wheel.

h the Potence.

i the Balance-wheel Pinion.

k the Counter-potence, which also carries the other End of the fourth Wheel.

m the Spring-barrel.

n the Hook in it, where the out End of the Spring hangs.

o the Hook at the contrate Wheel, where the inner End of the Spring is hung.

r the fifth Wheel, with the Pin where the Detent is to stop.

S the upper Plate.

T the Pillar-plate.

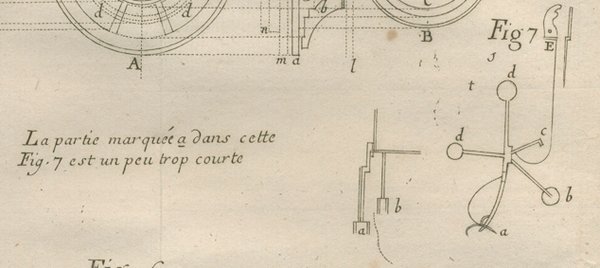

Fig. 7

Is the Detent, by which is the Discharge for winding up eight Times in a Minute. The Part a acts at the eight Pins on the contrate Wheel-arbor. b is a Roller acting against a Piece of Brass on the fifth Wheel-arbor. c is a Piece that stops against a Pin in the Rim of the fifth Wheel. dd are Pieces of Brass to make it in an Equilibrium with itself; and E is the Spring which acts upon it. The Centre of the Detent is at x in Figure 14.

The note in French translates as:

The part marked a in this fig. 7 is a little too short

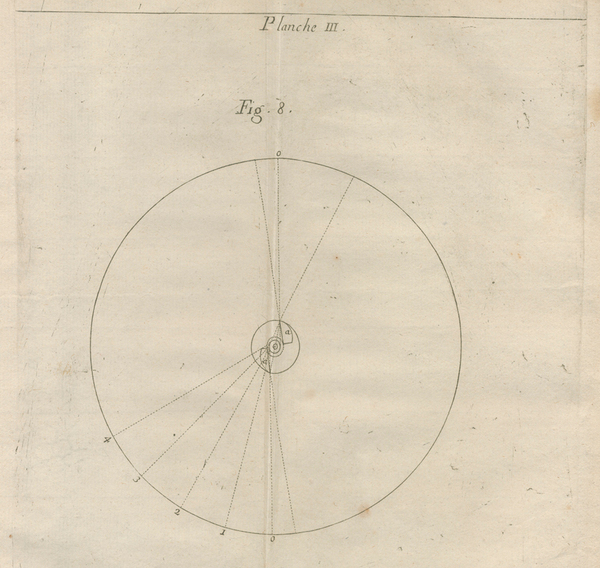

Fig. 8

aa are the Pallets of ten times the Size that they are in the Time-keeper. The dotted Lines from 24ths of the Circle, show the Power the Balance-wheel has to impede the Motion of the Balance by the Declivity on the Back of the Pallets, at any the same time whenever it shall have the greatest Power to give it Motion.

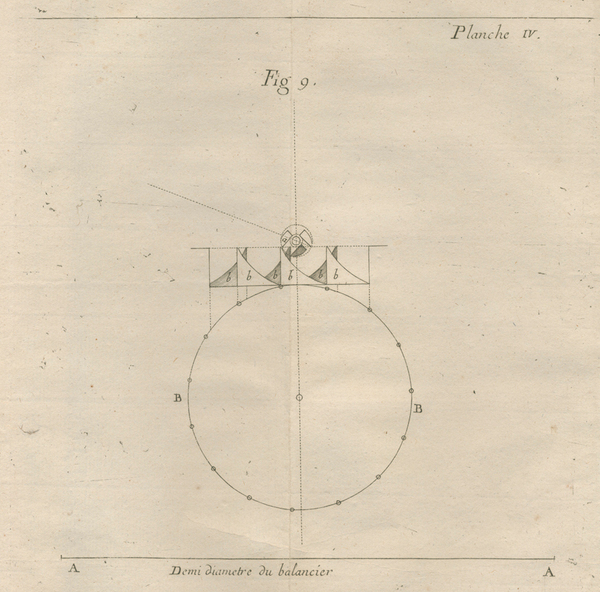

Fig. 9

Is to show the Proportion between the Balance, the Balance-wheel, the Balance-wheel Teeth, the Pallets, and at what Distance the Wheel acts from the Centre of the Balance. AA represents the Balance, BB the Balance-wheel, aa the Pallets, and bbbbbb the Balance-wheel Teeth.

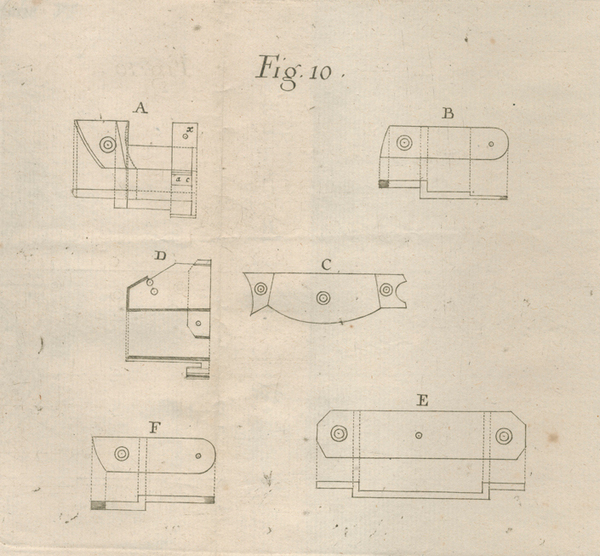

Fig. 10

A is the Counter-potence, with the Follower a, and a small Screw at c, to stop when at its proper Place, and x is the Centre of the fourth Wheel.

B is the Cock for the Minute-wheel.

C is the Steel Bridge.

D is a Cock for the contrate Wheel.

E is a Cock at the first Wheel.

F is a Cock at the contrate Wheel on the Pillar-plate.

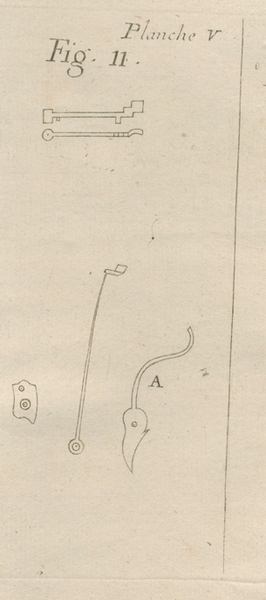

Fig. 11

Is the Detent, which is to stop the Balance before the Watch be down. It turns upon a Centre at t in Figure 14. A is the Locking-spring.

Diameter of the hole in the Socket. (Its wider end) about 0.19 of 1/4 inch.

Diameter of the upport pivot 0.22. Diameter of the lower pivot 0.09.

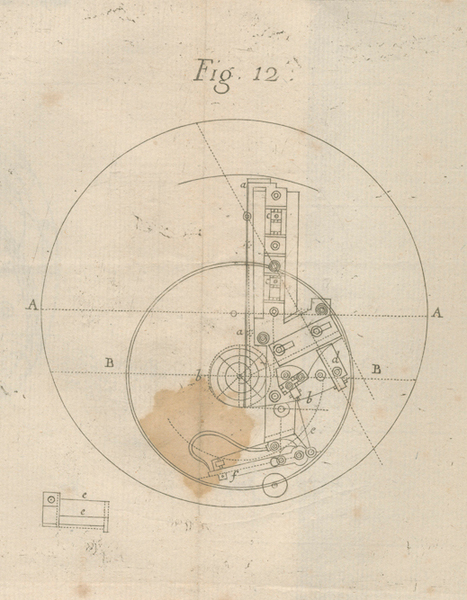

Fig. 12

AA represents the upper Plate. BB the Balance.

aa the Thermometer.

bb the Balance-spring.

cc Slider to adjust the Thermometer end-way.

d the Stud.

e the artificial Cycloid.

f a Piece to adjust it so as to bear properly against the Spring.

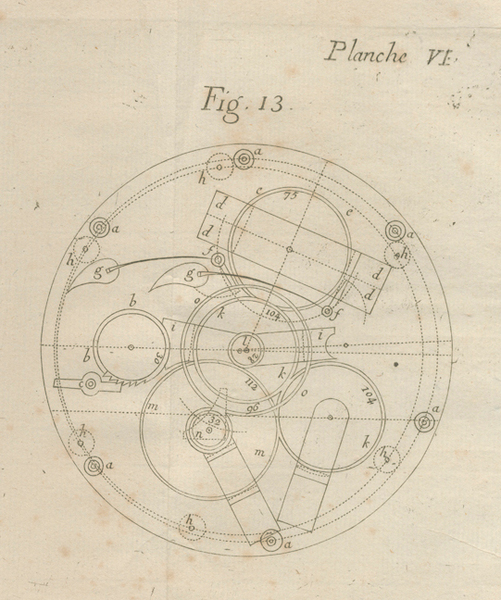

Fig. 13

aaaaaa the Feet of the Brass Edge.

bbthe Ratchet at the Spring-barrel.

c the Click.

dddd the Cock at the End of the first Wheel.

ee a Ratchet.

ff the Centres of the two Clicks which act in it.

gg the two Springs that act at them.

hhhhhh the six Pillars of the Frame.

ii the Steel Bridge.

kkk two Wheels that carry the Seconds, one being on the contrate Wheel-arbor, the other moving on the Cannon-pinion.

l the Cannon-pinion.

mm the Minute-wheel.

n the Hour-pinion.

oo the Hour-wheel.

Fig. 14

Sadly figures 14 and 15 are missing from the scans in the Cambridge Digital Library.

aaaaaa the six Pillars of the Brass Edge.

bb the first Wheel.

c the Centre-pinion.

dd the second Wheel.

e the second Pinion.

ff the third Wheel.

g the third Pinion.

hh the contrate Wheel, and the fourth Wheel.

i the Balance-wheel Pinion.

k the fourth Pinion.

ll the fifth Wheel.

m the fifth Pinion.

nn the Fly.

oo the Balance-wheel.

p the Potence.

rrrrrr the six Pillars of the Frame.

s the Stud.

t the Centre of the Detent, to stop the Balance.

x the Centre of the discharging Detent.

uu the upper Plate.

zz the Pillar-plate.

Fig. 15

Sadly figures 14 and 15 are missing from the scans in the Cambridge Digital Library.

Is what was designed for the Work on the upper Plate, which is now done in the Manner as represented in Figure 12.

For tempering the Balance-spindle, the Balance-spring, and the Pinions.

Before their being immersed in Metal (as just melted) let them be oiled over.

The Heat for the Balance-spindle 567 on Fahrenheit's Scale, the which is given by one of Pewter to 12 of Lead; but for the Balance-spring and the Pinions, let the Mixture be One of Pewter to 17 of Lead.

Each Turn of the first Wheel (or Fusee) is 4 4/7 Hours; so 5 1/4 of its Turns is just 24 Hours; and 6 1/4 is 28 4/7 Hours; and 6 9/16 Turns equal to 30 Hours.

Although the figure is missing, this is one of the most fascinating passages in the entire document, and at any rate doesn't appear to relate to the figure.

Harrison is achieving very precisely controlled heat treatment by melting defined alloys and then dunking his parts into the molten metal "as just melted".

The molten metal is guaranteed to be at approximately its melting point if it has only just melted, so he achieves a very repeatable heat treatment this way. And by changing the ratio of lead to pewter he changes the melting temperature of the alloy to gain continuous-valued control over the temperature. And on top of that, the part is kept in an oxygen-free environment for the bulk of the time that it is hot. Ingenious!

I'm not sure what the oil is for. To prevent the lead mixture from sticking perhaps?

FINIS.