I liked my dining table, but it was a bit longer than necessary. It occurred to me that I could cut it in half, so that's what I did.

Here's the "before and after":

The table is too large to get in/out of the house with the legs on, so the legs have to come off inside the house:

I used the tablesaw, with blade retracted, as a workbench. I would have done this work outdoors because the tabletop is quite large, but it was raining so I preferred to just manage inside the garage.

I clamped down a guide for the circular saw and started making the cut. It was a bit of an awkward reach towards the end, and I obviously wasn't paying attention properly, as my cut wandered away from the guide. D'oh!

I moved the guide over and had another go, and this time succeeded, although the tabletop will now not quite be a perfect square. Never mind.

I didn't cut all the way through the strips of wood at the edges with the circular saw, because I didn't want the tabletop to crash to the floor at the end of the cut, and I didn't want to cut into the tablesaw. I finished the cut by hand.

I initially understood this to be a solid-wood tabletop with an oak veneer on the top, however I now discovered that it was an MDF tabletop with an oak veneer on the top and some other veneer on the bottom! What a scam. If I'd known this when I started I would probably have chucked it away instead of trying to cut it in half.

Now we need to work on the underside of the tabletop, so to avoid scratching the top surface I put a blanket over the tablesaw:

My plan here was to take the edge piece off the end of the offcut and glue it on to the now-shortened tabletop. To start with, we need mitred corners on the edge pieces that are already there. Spot the deliberate mistake:

For some reason, my first thought was to cut the mitre backwards... I don't know why. Fortunately I realised my mistake before I got too deep. I marked the mitres with a "speed square", which is a tool I bought years ago after reading something that recommended it, but have found to be useful for almost nothing other than marking 45° angles.

After I cut my mitre, I found that the triangle of wood on the end was still attached with glue and a nail. I pried it off with a screwdriver, but in so doing I also dislodged the edge piece that I wanted to keep, so I glued that back down and clamped it, but I squeezed the clamp too hard and broke the handle off! This is not my day.

I plan to copy the broken part in FreeCAD as a CAD Dojo project and then make a replacement out of aluminium using the CNC machine.

I've left a few apprentice marks, and ripped off a bit of the veneer, but I think this is going to work:

Now I just need to liberate the edge piece from the offcut so that I can glue it on.

I found that the MDF would split more readily than the edge piece would separate from the MDF.

But using fine engineering techniques, and definitely not any brute force or ignorance, I eventually got it off:

Quite a lot of MDF and veneer came off with it, so I then cleaned the glue surface up with a chisel:

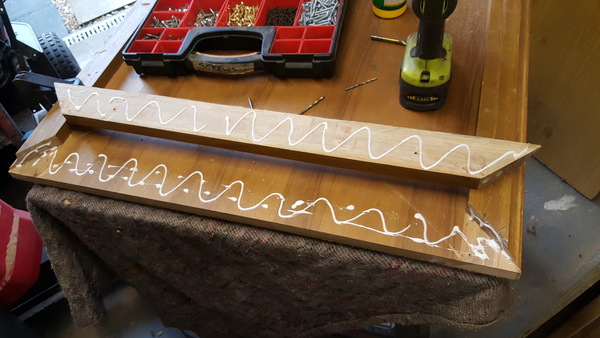

I glued both surfaces:

And put it in place, with a couple of screws to hold the glue joint nice and tight:

I found that the ends of this piece were bent away from the tabletop (probably due to the fine engineering techniques used in separating them earlier), so I clamped them down to help the glue joint:

Now we're getting somewhere. Just need to cut the side pieces down:

The side pieces have a slight curve in the bottom of them, which I have simply ignored for now. If it bothers me that they're wider at one end than the other, I can always take it apart again and run all of these pieces through the table saw to take the curve off. But I don't think I care enough.

I planed a small chamfer on the cut edge to make it match the other edges a bit more:

And finally took it inside and put the legs back on:

That was quite a bit more of an ordeal than expected, and probably not worth it now that I know the whole thing is only made out of MDF.