Last modified: 2025-01-09 20:01:22

< 2025-01-07 2025-01-11 >The idea of making anti-friction wheels by putting lots of different pivots all over the aluminium frame sounds like it's more trouble than it's worth.

So what if I designed a 3d-printed "bearing block" with 3 anti-friction wheels inside? Then I can just bolt it to the frame and pass a shaft through it and it is constrained in 2 dimensions.

The wheels want to be very accurately concentric with the shaft, probably rough out the wheels, Loctite to the shaft, true up on the lathe? Between centres? If I do them all at the same time it could be quite efficient.

Then it just needs a block that can bolt to the extrusion, take 3 pivots for the wheels, and allow the "real" shaft to pass through the centre.

Then you've got the problem of how to constrain the shaft axially. I was kind of thinking that there should be a hard stop at one end and a spring-loaded stop at the other, so that it is always pressed against the hard stop but not too tightly.

For most of the shafts just blocking off one end of the block would be fine (either solidly, or spring-loaded). But the most important one is the escape wheel shaft, and that has a gear on each end.

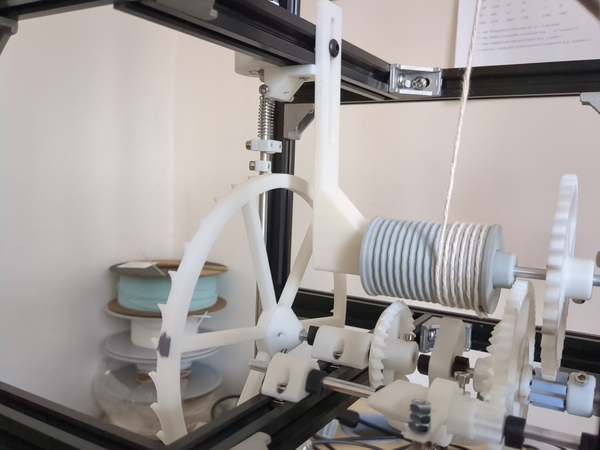

Old pic but you can see the "long" bearing block here:

So that one will need an arm that reaches around the bevel gear to act as a stop at the back. But what at the front? Maybe we have a shoulder on the shaft and press against that? Or maybe we say the reaction from the pallets will always load it against the stop at the back and we don't need anything at the front?

I think start by saying we don't need anything at the front and then add something later if it turns out to be needed.

So, I guess CAD an anti-friction bearing block. And do I leave the shaft diameter at 5mm or switch to something smaller? I reckon more convenient to leave it at 5mm for now.

The block needs to be made of 2 parts if the wheels are going to be Loctited on to the shafts, else it won't be possible to get the wheels in.

So there we have 1mm holes for the 3 anti-friction wheel shafts, big hole through the middle to allow the real shaft to pass through (and enough gap to see it working), holes to bolt the two halves together, holes to bolt the arrangement down to the extrusion, and a hole on the "cover plate" side to allow bolting some sort of shaft end stop, flexible or otherwise.

Having the wheels all in the same plane allows it to be quite compact, but obviously you can get larger wheels in the same footprint if you stagger them.

And I will want a "double" anti-friction wheel block for the escape wheel. Maybe could just have 5 wheels instead of 6?

I printed a first iteration of the (single) anti-friction wheel block, but it's not going to work because it is too wide, the arm-catching shaft is too close to the escape wheel shaft.

So need to either make it narrower, or maybe just make them special to constrain 2 shafts, since (for now) I only want anti-friction wheels on the remontoire stuff anyway, I'll have:

And that's all I need? So a generic one is maybe no use at all.

< 2025-01-07 2025-01-11 >