Last modified: 2025-01-05 10:01:51

< 2025-01-03 2025-01-07 >I'm going to try again to get it to run down with the clockwatcher taking a trace, and this time I won't disturb the cables etc. while it's going.

If the clockwatcher has a connection problem this time then I'll try to debug it.

Started at 12:50.

Meanwhile, I can CAD and print a larger gear for the winding drum to increase the running time.

I only have a tiny amount of the white PLA left, hopefully the machine realises it has run out and lets me load a new spool. It did! Good.

I asked ChatGPT what sort of string is best to use. It suggested low-friction low-stretch string (duh) and suggested that braided polyester is a good choice, so I've ordered some braided polyester string.

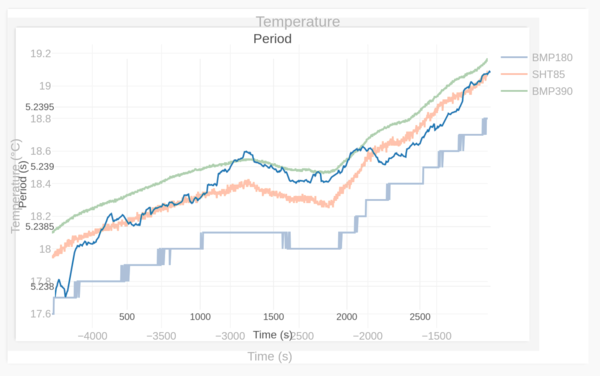

Check this out:

Kind of looks like period tracks temperature pretty closely! Hotter makes slower, as you'd expect.

It ran for about 90 mins before running out of string:

So, yes, looks like it very obviously slows down with heat, as expected. And it stayed within about 2.5ms of period variation over the 90 minutes, which would correspond to varying by 41 seconds per day.

I'm going to fit the bigger gear and see if it will run. I went up from 43 teeth to 100 teeth.

With 12x drive nuts and reduced remontoire weight, it is running, with about 200 degrees amplitude. And I guess we expect it to run for about twice as long as before because the gear has about twice as many teeth.

During the 90 minutes, the weight dropped by maybe 50cm and then I was out of string. Which means if the weight can drop by 2 metres then it should have run for 6 hours before, so about 12 hours now, if it had enough string. So about a factor of 700 remaining.

Started at about 15:04.

It stopped because a drive weight nut rested on a beam of the frame. Need to make it not do that. I might be better with a "bottle" type drive weight where I can more easily constrain the outer shape, and more finely adjust the weight within.

< 2025-01-03 2025-01-07 >