Last modified: 2024-12-09 17:04:31

< 2024-12-08 2024-12-10 >I'm going to put a fourth M12 bolt on the balance wheel, and reset the pivots and pallets, and let it run and see what it looks like.

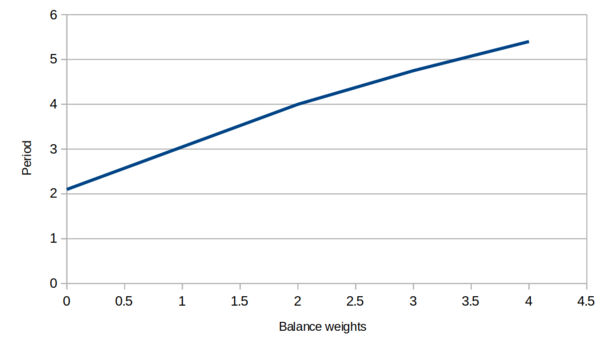

The free-swinging balance wheel has a period of about 5.4 seconds. 5.4/4.75 = ~1.136, so only about 14% slower, looks like diminishing returns here.

Or maybe not, seems reasonably linear actually.

It should run for about 3.5 hours. It's 12:10 now so should stop around 15:40.

Look at this:

There is a weird sort of pattern in the unaveraged amplitude at about 243 degrees, independent of the varying amplitude. I think maybe this is the balance spring hitting the balance shaft again?

And amplitude/period shows a "gap" at about 244 degrees:

I guess if there is enough energy to overcome the resistance at the point that the spring touches the shaft, then it tends to go even further.

It stopped early because Emma knocked it.

But that's still enough to see that it's not working very well.

Obvious problems are the usual suspects: one pallet catching the escape wheel tooth on its reverse swing, and the spring touching the balance shaft.

It looks like the historical data thing is actually not working correctly.

If I ask for the "last hour", I always get the same output, not matter when I ask. What is wrong?

I did notice that the timestamps in the database are in microseconds and in the URL are in seconds, but if that is the problem why does it yield any data at all?

Oh, the Cursor code has added a second, unnecessary, timestamp field based on the Unix time that the record was inserted.

So I will want to get rid of that and just use total_micros, but in the meantime it seems

like it should roughly work? Why aren't I getting back the same data that I'm seeing in the

live view?

OK, I'm an idiot, I think it might be working fine, it's just showing me all the data from the last hour, including the stuff from before I "reset" the view after setting the pallets etc.

One issue is that changing the "moving average" setting doesn't redraw the plot in historical mode.

Fixed.

And I accidentally reloaded the "live" viewing tab while testing this, and can confirm that I am able to retrieve the historical data. Good.

I'm wondering about adding an extra reduction stage into the train. Although I worked out that I thought I could do it with 3 stages of 20:1 reduction, that would be like a 120-tooth wheel and 6-tooth pinion, which seems maybe a big ask? Perplexity reckons adding a 4th stage would be likely to make it more efficient overall despite the extra stage, because it would allow use of more favourable (larger) pinions.

I was thinking that if I want the weight to drop down the side of the case, but I want the winding drum to have a big gear on it, then maybe I should put the winding drum in the middle but loop the string over a pulley at one side? That way the size of the gear isn't pushing the winding drum away from the side of the case (and, worse, the top).

Yes you lose a bit of efficiency in the pivots on the pulley, but probably the extra ~5% (if you assume 10cm closer to the top of a 2 metre drop) distance is worth it.

And I think I'm ok with using ball-race bearings, pillar blocks, bicycle chains, etc. on antyhing that lives on the train side of the remontoire, because variations in the oil shouldn't affect the escapement.

So we've got the weight on a pulley (2:1) falling the entire height of the clock case.

The string loops over a pulley at the top of the case and comes down to the first shaft in the train.

Then we have 4 stages of about 9:1 reduction, then the remontoire and finally the escapement.

That is 1000x the overall reduction that I have at the moment, which means it should run for 3500 hours, or 145 days. The remaining factor of 2.5 comes from:

I think a factor of 1.5 on each of those is reasonable, which overall gives us 35% more reduction than is needed to run for a year.

I think for the time being I build just the "top" part of the clock frame. Leave the vertical tubes open at the bottom and then they can drop on top of "legs" later.

Let's put the train pivots 125mm apart vertically. That allows for just under 250mm combined diameter of wheel plus pinion.

And I'll build the frame to allow a lot of adjustment in the pivots.

Including space for the dial etc. I think this top part needs to be a bit over a metre tall.

One issue with having the remontoire directly on the shaft with the escape wheel is that the clock needs to be quite deep. It needs to be deep enough to fit the pinion, catching-arm-shaft-engaging-gear, remontoire bevel gears, and escape wheel, and half the balance wheel diameter. Maybe I don't care? It just feels out of proportion to have most of the case empty, and then one super-complicated shaft that crams everything in a tiny space.

I got fed up of trying to plan it out on paper, will arrange some stuff in CAD to work out how I need to make the frame.

Actually I'm just going to go with aluminium extrusion, leaves flexibility to move things around, and saves faffing about with welding.

Something like this: