Last modified: 2024-11-13 21:50:09

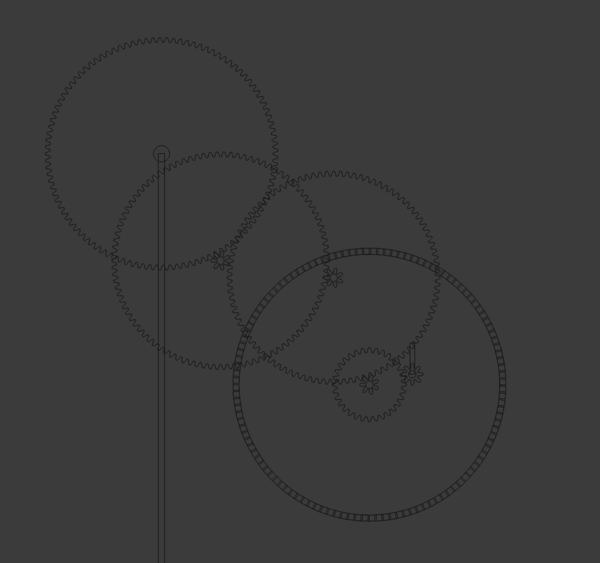

< 2024-11-11 2024-11-13 >Yesterday I wrote a load of nonsense about the clock, but I think I reached this as a sketch of the design:

For gearing:

And for the rest:

For bearings:

So the plan is to lay out the clock in sort of schematic form in FreeCAD and see that it looks like it is going to work, and then as quickly as possible transition to making the escapement. Once the escapement works we'll know how fast it ticks, then the gear train can be recalculated and I can build the rest of the clock.

For making bevel gears for the remontoire I wanted to use https://github.com/looooo/freecad.gears but I can't install it in the addon manager because of some git error about not being able to find "master" (but I checked on github and it is still using "master" and not "main"). And when I tried to install it again it is saying it is already installed and up to date, but the workbench isn't visible anywhere.

If we allow 7-tooth pinions then to get 1:2880 we can use 7:105 7:98 7:96. One problem is there is no simple ratio

to take the minute hand off this. The second shaft is quite close, takes about 54 mins per rev.

Here's a way to lay that out:

That shows the going train, from the drive weight (represented by the tall thin rectangle) to the escape wheel, and including the shaft adjacent to the remontoire.

Does not show the motion work, balance, anti-friction rollers.

Next step is to design the escapement in more detail so that I can actually make it and see that it works.

Also, I want some optical electronic measurement system on the balance, with a quadrature encoder so it can tell me both the period and the amplitude. Could be like https://incoherency.co.uk/blog/stories/3dprinted-light-gate.html but with 2 channels?

It seems like applying a polar pattern in FreeCAD is O(n^2), making a 120-tooth escape wheel is extremely slow.

One issue is end-shake on the escape wheel will mess up the interaction with the pallets, maybe anti-friction rollers are not the best idea for this? Or maybe it's still fine, just needs some other feature to locate it axially.

I have this:

(You just have to imagine the lower pallet).

The escape wheel is 220mm diameter.

I'm going to start the escape wheel printing now, even though I don't have a design for the frame yet. I think the white PLA will run out and I'll get to find out what happens then. Hopefully I get to complete the part with a different spool.

The frame will need provision for cone bearings at the top and bottom of the balance shaft, probably the small ball bearings on the escape wheel shaft, and space to let the drive string hang below, although we could run that over a rod at the side if necessary. Also needs to hold a balance spring, but I can easily add that later (ha).

Maybe we fix the lower conical pivot in the frame but allow the top one to be moved around to help align the balance shaft. And space the escape wheel shaft from its bearings with some collars to adjust depthing.

When it ran out of filament it moved the head over to the filament purging area, but didn't pop up any message on the screen (maybe I didn't wait long enough). I took the empty eSun spool out of the AMS and put a Bambu spool in its place and it resumed on its own with no further effort from me. I don't know if it was necessary that the Bambu spool had RFID identifying it as white PLA (which matched what I had configured for the eSun one) or if just populating the same slot is sufficient.

Here's a frame 3d-printable in two pieces:

- the top one is bolted down from the top, not visible here.The random holes in it are for attaching other parts later (specifically the balance spring). I don't know exactly what I'll make or where I'll want to put it, but drilling holes in 3d prints after the fact doesn't work very well, so hopefully one or two of these holes will be useful.

I can go and make the shafts now.

The balance shaft is 330 mm long, with points on the ends.

The escape wheel shaft is 200 mm long

Lol, my 5mm aluminium rod is just slightly too short, so they're 320 mm and 192 mm long instead.

Also I was planning to make the conical pivots out of M12 bolts, but all of my M12 bolts are only part-threaded, so would stick out unnecessarily far. I'll just 3d print the pivots for now.

I'm having trouble with bed adhesion with the Bambu PLA. It could just be the shape of the parts, strange that it seems worse with Bambu PLA than eSun though. I'm going to try out the smooth bed.

Smooth bed worked, and after the print finished the parts felt very well stuck down. So I reckon bed adhesion is better on the smooth bed.

I put the escape wheel bearings in the vice and spun the escape wheel and it was wobbling pretty badly. I put some pieces of paper in between the collar and the gear to straighten it up.

I reckon the wobble is less than 1mm now, still worse than I imagined settling for though.

Also, due to the grub screw, it is slightly out of balance, I have added a sticky pad weight to balance it out.

I have all the small parts from my CAD printed, just need the balance wheel and the frame parts.

< 2024-11-11 2024-11-13 >