Last modified: 2024-09-13 15:25:41

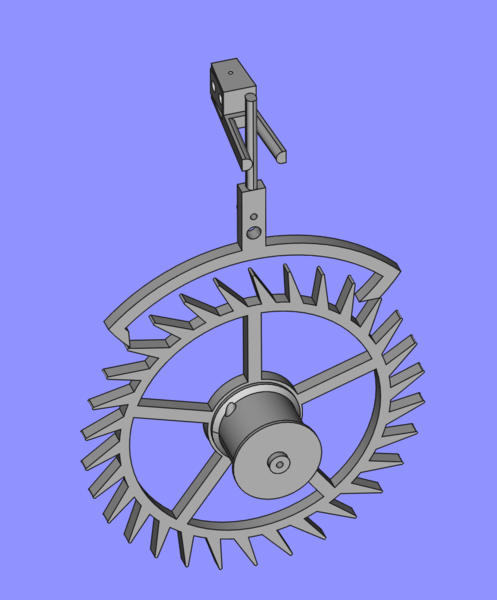

< 2024-09-10 2024-09-14 >So the plan today is to make some a finger/fork that clamps onto the wire, and make an anchor with a matching part, and then see if we can run the deadbeat escapement with the anniversary clock balance wheel.

First, CAD.

Maybe?

It looks like the kind of complicated thing you design when you don't know what you're doing.

It allows me to move the fork up/down to vary the lever ratio, and to move the wire forwards/backwards to vary the clearance in the fork, so hopefully it has all the adjustment I need. And obviously I can clamp it higher/lower on the wire to change the ratio between how much the balance wheel turns and how much the fork wants to turn. (If you imagine the wire wants to be twisted uniformly along its entire length, if the fork is 1/10 of the way from the top to the bottom, then unconstrained it would do 1/10 as many rotations as the wheel does).

And then the next question is how I'm going to suspend the wire above the mechanism. Maybe I have to make a sort of wooden frame? Surely there's something easier.

Maybe I screw a piece of 3x2 to the rafters, above the vice, and then clamp the wire to the wood, and position the vice so that it interacts nicely with the mechanism.

https://www.youtube.com/watch?v=7EEG-fOk8MA

Issues are:

For now I think just make another anchor, with a larger locking surface, and wider lever so that it fills the fork better.

Hasn't really helped, it still keeps fluttering.

OK, this was actually a geometrical error in my anchor.

This is what I have now:

You can see at the perimeter of the escape wheel there is now 2 circles, and the end of the exit pallet & start of the entry pallet lie on the inner circle. Previously the outer circle was the only one, which meant that as one tooth left the exit pallet the next tooth landed right on the corner of the entry pallet.

The inner circle is set up so that the tangent line from the circles to the anchor pivot is 1 deg. apart, which means the anchor has moved 2 degrees beyond the point that a tooth hits the corner of the entry pallet, before the other tooth escapes the exit pallet. Hope that makes sense.

The other thing I noticed was PrusaSlicer put the seam right inside the locking face of the exit pallet! Which meant it was printed really badly. I will move the seam somewhere else this time. The seam can go literally anywhere except on the working faces!

Also, this is actually drawn wrong in another way. In the central position the pallet faces should be halfway across the perimeter circle (modulo extra for locking), but I've got it set up so that the exit pallet is fully open and the entry pallet is fully closed.

It is looking a bit more convincing, still a bit fluttery though.

This page on anniversary clock repair - https://www.clockworks.com/clock-repair/clock-repair-help-1.html - says:

To find out exactly where this [fork] should go, hold up the suspension to the clock and get an idea on the height it should be put at. It should be able to whack the verge wire back and forth and should be positioned so it's sticking straight out of the spring at a 90 degree angle. Its height will have to be low enough on the verge to keep the clock running, but high enough so the clock will not flutter. Fluttering is the term used to describe the clock running 300 miles an hour even with the balls hung and is the result of having the fork set to low.

What would having the fork set too low do? It would mean that a given movement of the fork corresponded to a larger movement of the anchor, and vice versa. But why would that make it flutter?

I'm thinking it flutters because the balance wheel has too much moment of inertia. Let's say the escape wheel tooth ends up on the impulse face of the pallet, and pushes the anchor, which rotates the fork, which applies some torque to the spring, and then the escape wheel tooth escapes from the pallet and the anchor is free. If the balance wheel hasn't moved far enough yet (because its moment of inertia is too high), then the fork will be pulled back by the spring, and can flick the anchor back the other way, even though the balance wheel hasn't changed direction. Basically forget the balance wheel, just imagine something is pulling the anchor towards the centre all the time.

If we humour the page on clock repair, then what we want to do is move the fork higher, but I already have it as high as it can go. The purpose of moving the fork higher is to make a given movement of the fork have less effect on the anchor. We can achieve the same thing by moving the wire closer to the anchor, although I might be at about the limit in that direction as well. I'l give it a go though.

https://www.youtube.com/watch?v=V2ZCK9fv1O4

Well this is better now. I've moved the wire support further down so that I can move the fork further up, and removed most of the bolts from the balance wheel to reduce its moment of inertia. Observations include:

We might be able to solve the flutter by making sure that the centre point of the escapement puts the escape wheel teeth on the locking face rather than the impulse face. Then even if the fork snaps the anchor all the way back to the point at which the lift began, the escape wheel tooth will still land on the locking face, and it doesn't flutter. But does that mean we'll be spending too much energy on frictional rest and not enough on impulse? Maybe.

All of the impulse will be delivered "after the line of centres", whereas you'd rather have an equal amount each side. But needs must.

Another thought that occurred: do anniversary clocks basically work by accident, rather than by principle? Do you really need all the weights and springs and moments of inertia and frictions to be in perfect balance, otherwise it just doesn't work? Not sure.

Let's try an anchor where the mid-point places the escape wheel teeth on the locking faces.

There isn't that much room, because you need the exit pallet to not crash into the escape wheel when the impulse begins on the entry pallet:

That's about the best I can do. It doesn't have a lot of safety margin around the centre point. And it only has 3 degrees of impulse and 3 degrees of drop, so 50% of the escape wheel motion is wasted. Not really ideal, but if I increase the width of the impulse faces then the exit pallet crashes into the wheel before the entry pallet can accept the tooth.

I'll see how I get on with this one.

Still a bit fluttery - but perhaps the issue is the rounded corners on the pallet faces. So let's try a version with more safety margin and more impulse, and explicit fillets. And failing that, I'll have to sit and think about it.

Still fluttery, so I have to sit and think.

Thinking about this another way: why wouldn't the spring simply snap the lever back to the centre as soon as the impulse is over?

The impulse doesn't take place instantaneously. The lever was already moving "forwards", else the escapement wouldn't have unlocked. As long as the lever moves forwards far enough during the time it takes to apply the impulse, then the next escape wheel tooth will land neatly on the locking face.

But the lever has to be pushed ahead of its natural movement during the impulse, otherwise there is no impulse! So any lever which is not snapping back to the centre is not actually applying any impulse.

It's possible to apply some impulse for the first part of the movement, and then slow down and let the balance wheel "catch up" before finally letting the tooth escape.

OK, how then?

Not sure, but you agree that it is in principle possible?

Sure. Do other anniversary clocks exhibit the "snapping back to centre after end of impulse" phenomenon? Let's find out.

Yes! Check out https://www.youtube.com/watch?v=-EsKQANaKY0 - the lever/fork very clearly snap back towards the centre after the impulse is over.

So you're saying this is approximately working as intended, and making it actually work is just a matter of magically balancing all the forces so that it just happens not to flutter?

< 2024-09-10 2024-09-14 >