Last modified: 2024-04-28 20:26:25

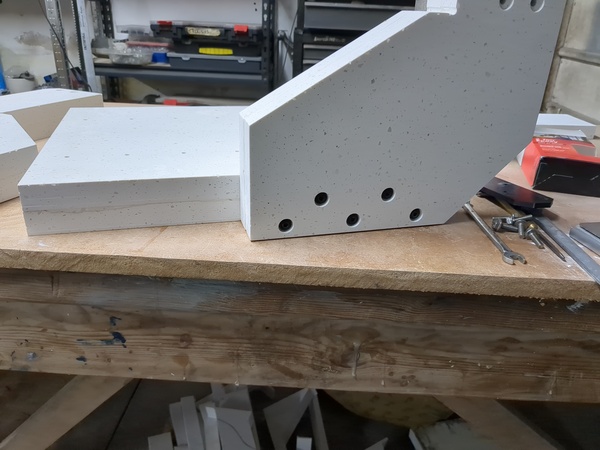

< 2024-04-26 2024-04-28 >The upright bolts nicely to the inserts I bolted in:

Not perfectly square, but I'm not sure how bothered I am. Maybe worth addressing just to improve the contact surface area:

The rails and BK12 bolt on nicely to the gantry, thankfully:

And works when I drive it with the drill:

https://www.youtube.com/watch?v=Tj82risYJTE

That's good because it means everything is square and parallel enough not to bind up.

For fitting inserts to the other side of the baseplate, I'm going to need to widen this hole:

I ummed and ahhed about what to do, but then decided that since I'm using the template to align it for gluing anyway, the actual hole doesn't need to be very precise. So I widened it using a Dremel tool:

And now the inserts fit in on the template, and they're gluing now. I'm also gluing the BK12 and linear rail inserts for both the Y axis and Z axis, which is all the gluing I can do until I drill more holes.

I've been reading "The Modern Clock" by Ward Goodrich, original version publish 1905. I am becoming intrigued by the idea of trying to make an accurate pendulum clock. Goodrich suggests:

I also like Hefetrueb's clock ( https://www.youtube.com/watch?v=Q9XJ3UHtpf0 ) but I don't know if I'd want the grasshopper escapement. I do like the idea of reducing the number of wheels by making the escape wheel go around once per 4 minutes and making the dial show seconds on 1/4 of a turn. I also like the roller pinions and anti-friction rollers, although I would use PTFE or something instead of lignum vitae.

I am not sure why Harrison used a remontoire on a weight-driven clock.

I think it would be cool to make the clock run for 1 year on a winding, not sure how practical that is though. I don't mind dedicating the entire height of the room to it, so the weight can fall the entire height of the room. And for that matter you might be able to put a vertical date scale, with a pointer on the weight!

< 2024-04-26 2024-04-28 >