Last modified: 2024-03-09 21:37:35

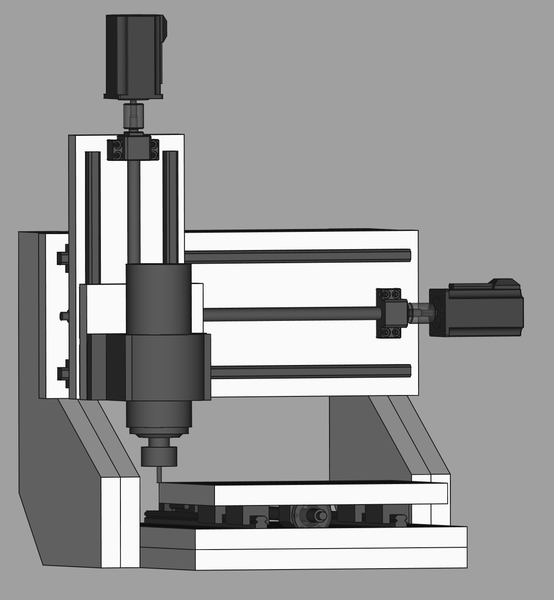

< 2024-03-05 2024-03-10 >Now with mounting holes in the ballnut holders & BK12 bearing holders:

Also I've shifted the ballscrews so that they're centred in the space between the adjacent planes.

Actually, perhaps I should shift it so it is closer to the "moving" surface, and that way I won't need to gouge out such a big channel in the "stationary" surface? Especially if I cut the top off the ballnut holder. I'll have to cut a bigger pocket for the ballnut holder, but that is a lot less work than cutting a big pocket for the entire length of the screw.

I've started on hollowing out the ballnut holder attachment points:

The cut-out is 11mm deep, will obviously have rounded corners in practice but I've left room for that.

Suggested order of operations for construction:

I might leave the "loose" end of the ballscrews unsupported, in which case it doesn't really matter if I can't turn them on the lathe because they don't do anything anyway, just need to be a clean enough cut to get the ballnuts back on, which can probably be done adequately with the grinder.

Instead of winding the ballnuts on to a dedicated holder, perhaps I could use the ballscrew offcuts as holders? Just need to cut the ballscrews down before I remove the ballnuts.

The things that need doing are:

What are these sorts of spacers/washers called?

ChatGPT can't tell me.

Still needed in CAD is: