Last modified: 2024-03-09 21:38:13

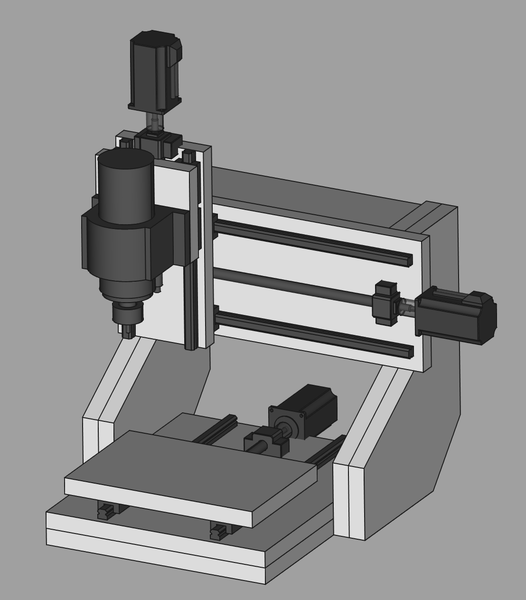

< 2024-02-27 2024-03-04 >I've finally put all the ballscrews in.

Z ballscrew: 200mm threaded

X linear rails: 450mm

I think I'm going to use the BK12 bearing blocks for the restrained end of the ballscrews, but just 3d print some bearings holders for the other ends, because the other end only needs to be constrained at all to prevent whipping, if I make them myself then I can make them small enough to clear other parts, and it's cheaper that way.

I will need to turn down the ballscrews that I have to suit the required length, but I believe the lengths I have chosen are standard sizes so that if I need replacements I can buy them.

I'm going to 3d print the motor mounts (at least to start with). They won't see any thrust loads because the BK12 bearing blocks take all of the thrust load, they'll only see torque. I expect a decent 3d print would be adequate. Corollary to that is that the motor mounts should be designed primarily to react torque, and hardly any thrust at all. One important consideration is how easy it will be to get motors on/off once the machine is inside the tub. That was a major point of annoyance on the mini mill.

Still needed in CAD:

Interestingly, for the price of one genuine(?) Hiwin HGH15CA carriage from CNC4YOU, I can get 2x 500mm rails plus 4 carriages on Amazon. I think Amazon is definitely the place to start.

I didn't see 450mm rails available on Amazon so I got 500mm and may have to cut them down.

Update: apparently BK12+BF12 come in a pair, I can't seem to buy them individually. Oh well, I may use the BF12 then or I may 3d print my own.

I've bought:

Total: £213.71

I'll still need to buy threaded inserts and probably nuts/bolts, but I think that's the bulk of the cost already. Very cheap for what should hopefully be quite a capable machine (because I already have most of the expensive parts).

< 2024-02-27 2024-03-04 >