Last modified: 2024-02-25 19:51:53

< 2024-02-23 2024-02-26 >I had another look at the 1.5kW spindle motor and found that the wavy washer in the top that allows for thermal expansion is actually 2 wavy washers, and I had somehow assembled it with the waves out of phase with each other, which meant the spacing was too big. I fixed that and put it all back together and all is fine now. I've installed it in the CNC router and it works, and seems quieter than the 2.2kW one, so perhaps I should give that one the same treatment.

I do think I may have buggered up some of the bearing seals so that they're rubbing on the balls now, so it makes a slight rubbing noise at low speeds, and it did get warm to the touch after only a few minutes' use, so I may have to address it again. But I'm happy for now, it works.

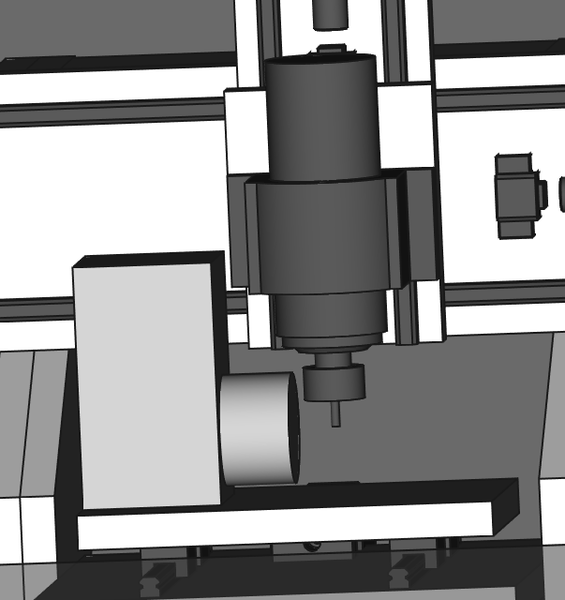

I put a very rough mockup of the 4th axis in the new machine CAD, and it looks like I may be able to use it, but I may have to slide the spindle down in the clamp, otherwise the spindle clamp could hit the 4th axis motor:

I think Gio is maybe not as useful for me as I initially thought. It doesn't handle edge cases very well (e.g. if there are too many buttons in a horizontal layout to fit on the screen, they don't wrap or scroll or anything, some of them just go missing).

So my new plan is to separate everything I have so that the GUI part is all self-contained, and then swap the GUI out for something using Gotk4.

Haven't watched it yet, but this Clickspring video on making hairsprings is bound to be interesting: https://www.youtube.com/watch?v=in6yWrlighI

< 2024-02-23 2024-02-26 >