Last modified: 2024-04-03 19:41:28

< 2024-02-14 2024-02-17 >Plan is to make the conrod for the busyboard. I want to use the milling machine, but that means I first need to address the Z backlash. I can see the pulley lifting up and down as I turn it back and forth, so it should just be a case of tightening up the nut that tensions it axially.

Actually I can also see the bearing at the far end moving around on its mounting b lock! Should I tighten it up? Or take it off entirely? I'll try tightening it up, and if it binds up the screw then I'll take it off.

Lol I can't tighten it up because the thread is stripped. I'll just remove for now, and if the screw whips around too much then I'll think of something else.

OK, well I tightened the axial tensioner nut thing, but the backlash is still there. So now maybe the theory is that there is no clearance between the inner races of the bearings, so tightening up against them can't take the backlash out. So the plan is to take it apart again, take the bearing plate off, knock one of the bearings out, and then put a spacer between the outer races so that the inner races can be tensioned.

Well I've got the bearing plate off and I can very clearly see that the inner races are not touching, so I don't see why I can't tension it.

Off the machine, with a bolt through the bearings, I can very easily get them so tight they'll barely turn.

I've put 3 washers underneath the tensioning nut, so that it is pushed further up and I can get the spanner on it more easily, and the plan is to try again to tighten it up.

I think the problem is that the grub screw won't get tight because the allen key keeps slipping. I've replaced the grub screw with an ordinary screw.

The leadscrew is still moving up/down by 0.2mm as I turn it back and forth! What is going on?? I did it even tighter and if anything it's got worse. I wonder if the outer races are shifting inside the block. I'll take the block out again and press the outer races together to see if they're actually constrained.

Nope, the outer races are plenty tight, I'm not convinced I even managed to move them.

So maybe the issue is that I was trying to clamp the screw by wedging a block to stop the head from moving, but there is too much flex in the system. Maybe I need to grab the screw with mole grips or something while I tighten the nut up. I really need to be able to get it so tight that it won't turn easily. If I can't get it that tight then I'm not satisfied that I'm actually getting it tight at all.

I don't really want to bugger up the screw with mole grips but I'm not sure I have much choice. I'll do it right at the end where it probably doesn't get used.

I think this might have sorted it! The bearings aren't filling me with confidence though, very "lumpy".

With it all back together the backlash looks like 0.09mm now, measured by jogging the axis with LinuxCNC. Much better.

I'm going to run the busyboard with all backlash compensation disabled and see how it goes.

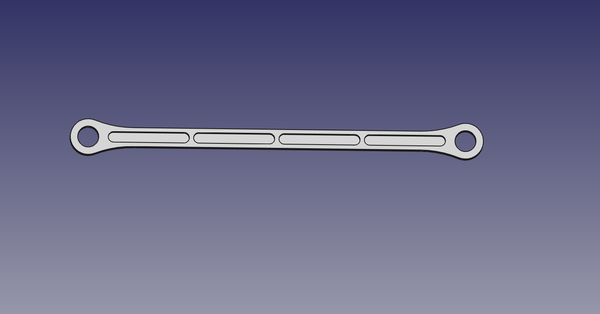

This is the conrod I want to make:

Maybe with a chamfer around the top surface.

Here's my clamping setup:

The aluminium is bowing up a bit in the middle, but I'm just going to run it anyway.

The first job will do most of the machining, then I'll run a chamfer, then I'll finish cutting it free.

Lol, I was trying to setup the coordinate system and the X axis made a rattling noise and bound up and alarmed. Sigh. This machine is nothing but trouble.

I'm not sure if axis has a bug to do with coordinate systems, or if I just don't understand, but having set the work offset correctly, the toolpath view is showing the tool miles away from the actual path. I'm just going to run it and see what happens. Need to ditch LinuxCNC and get grblHAL on it though.

It turned out that it was cutting in the right place, the toolpath view is just wrong.

I really need a switch for the flood coolant on the cabinet. And maybe a flow restricter on the nozzle so it is higher pressure and less volume. And maybe an Arduino thing to pulse it on and off instead of having it continuously on.

Great, after completing the first operation, the Z axis alarmed out. Probably the bearings are too tight. I'm going to decrease the speed limit on all axes.

Actually, update: looks like I may be able to leave flood coolant on permanently now? It is draining fast enough I think.

Damn, the X axis has stopped moving. The belt had come off. I've hooked it back on but I'm not sure it won't come off again.

Ugh, it actually scrapped the part on boring the hole, but I couldn't tell because flood coolant:

I wonder if I have another bit of aluminium I could use. I thought I had several lengths of this and don't recall using them, but I can't find them now. Found a bit, let's try again. I've added a bracket to stop the belt falling off.

It hasn't worked, the belt has come off straight away again.

Maybe the plan is to dismantle this machine, chuck away the frame (maybe even convert it back to a manual mill??) and use the leadscrews and motors for the machine I keep talking about building.

But for now I'm just going to have to use the CNC router to make this part. I'm out of time for today though. This evening I should do some more musing on what to do about the milling machine.

The leadscrews are 1605 as far as I can tell, and approximate lengths are:

This is a great example of the kind of thing I am after: https://www.youtube.com/watch?v=MnYmvph5MmU

It does have drawbacks compared to the existing milling machine though (mainly Z travel, potentially lack of torque at low spindle speeds). Z travel is very useful for drilling, because drill bits are long, but also useful for using the 4th axis.

More of the same machine: https://www.youtube.com/watch?v=pjhFVff9gW8 https://www.youtube.com/watch?v=lsQHJYeh0kY

I do wonder if the kitchen worktop offcuts would be a good material to make it out of. They're very heavy, quite thick, and most importantly they're free.

< 2024-02-14 2024-02-17 >