Last modified: 2023-12-24 09:58:39

< 2023-12-20 2023-12-23 >Predictably, the watch had stopped when I got to it, but it started again with a bit of a kick. If I had put the hands on it I might have an idea of how long it ran for.

Measurements:

(Possibly wrong nomenclature, I've ordered them starting at the barrel and ending at the escape wheel).

As a sanity check:

Minute hand is on first wheel, so barrel turns once every 58/8 = 7.25 hours.

Second hand is on third wheel, which turns (60*48)/(8*6) = 60 times slower than minute hand.

Escape wheel turns 48/6 = 8 times slower than second hand, which means it completes one turn every 7.5 seconds, or 2 teeth per second.

Third wheel output tooth module: ~0.30

First wheel pivots: 0.9mm

I was wondering about making a mainspring barrel by coiling up dozens of turns of the piano wire inside a very thin case, and letting it spin comparatively fast. Having the barrel spin fast is an advantage because it reduces the ratio required in the train to the escape wheel, and therefore reduces the torque required. It does mean you need more ratio to the hand though.

The wire would fix to the outer barrel by poking through a hole in the end cap, and fix to the inner shaft by poking through a cross-hole.

Since a barrel constructed this way would be very thin, you could let it cover the entire bottom surface of the movement (or top surface, for improved exhibition caseback viewing), and transfer its "fast" output into the main body of the movement with the central shaft, then have a counter-wheel to slow it down once and then a wheel on the hand to slow it down again, and the "fast" shaft is then only sped up with a very short train to drive the escapement.

I think I should make a barrel like this just for the experience if nothing else.

A 45mm area with 4mm shaft would give 20.5mm radius available for turns, and 0.25mm wire would fit 82 turns, which would be a length of 3155mm. I only have wire in 1m lengths so I'd probably only get about 25 turns. For a 12-hour runtime it would have to turn no faster than once every 30 mins.

This eBay listing has a good range of piano wire: https://www.ebay.co.uk/itm/255953572857 - lengths from 1m to 9m, and diameter from 0.14mm to 1.6mm.

So I now have three contenders for the movement layout, depending on how the mainspring barrel works:

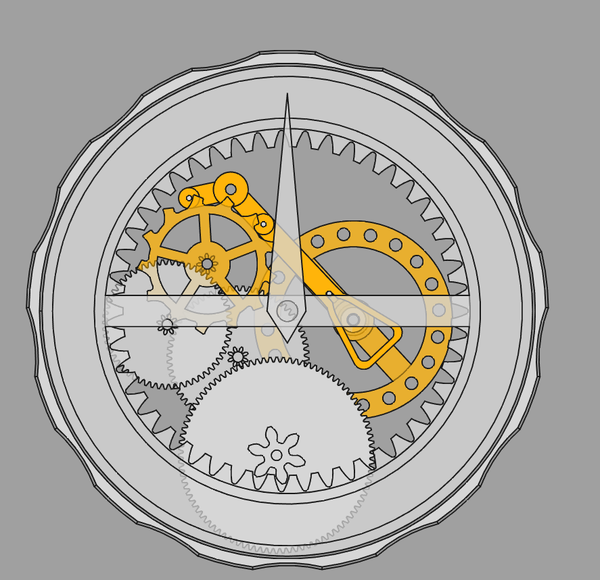

This is what I've been laying out in CAD so far, something like this:

For 12000 bph.

Though note it would need 1 more gear in the train at module 0.3 instead of 0.2

Total gears: 8

Pros:

Cons:

Let's take the mainspring barrel out of the pocket watch, and say we get 4 turns in 12 hours, so it turns once every 3 hours. So the centre-hour-hand needs to mesh off the barrel output and have 4x as many teeth so that it turns 4x slower.

Since the pocket watch's output gear has 60 teeth, we can't fit 4x as many on the hand wheel, so we'll add a second gear to the output.

The pocket watch barrel ends up 12mm away from our centre, so we need some (say) module 0.3 gears with 1:4 ratio, with 12mm between centres. I think they need to sum to 80 teeth. 16 and 64?

Barrel turns in 3 hours. First wheel turns in 21 minutes. Second wheel turns in 126 seconds. Escape wheel turns in 15.3 seconds, which is a bit over 6100 bph. Would look a bit like this:

The brown part is the mainspring barrel from the pocket watch.

We could easily change all the pinions to 6 teeth, which would change it from 6100 bph to 11000 bph, which is probably OK.

Total gears: 10

Pros:

Cons:

The idea with this one is we make a very thin barrel spanning almost the entire movement, and the outer is coupled directly to the winder like in the "hollow barrel" idea, except instead of making room for the gears by making the barrel hollow, we instead make the barrel thin and let it turn very fast.

This then implies a 2-step reduction for driving the hand, but means we don't need too much reduction for driving the escapement.

Let's say the barrel turns once in half an hour, so it is 24 turns for a complete wind. So we need a factor of 24 slow-down to drive the hand, and a factor of 240 speed-up to drive the escape wheel.

This:

Which has a solid disc at the bottom which would be the mainspring housing, and then the 24x reduction to the hand, which rotates concentric with the barrel output shaft.

If we made the mainspring really strong, we might be able to get away with the "thin barrel" design but with the barrel doing only 1 turn in 12 hours, which would then mean the hand can be coupled directly to the barrel arbor, but would need an extra wheel in the train.

Total gears: 12

If we make it 20 minutes for a turn of the barrel, instead of 30, then we can probably lose a gear (and associated pinion) in the train, which would bring it down to 9 gears total, only 1 more than the "hollow barrel" design, and without the requirement for cutting internal teeth. But it would then require 36 turns of the winder every 12 hours instead of only 24 turns.

But actually, I don't care about that, because it's hardly going to be a watch to wear everyday, and winding it up will be a treat. The more turns it needs winding, the more often you can wind it! The issue is going to be fitting 36 turns inside the barrel, and that the torque drop over 36 turns will be quite severe.

Pros:

Cons: